Download Planmeca Compact

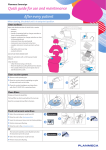

Transcript