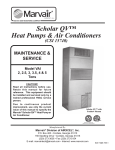

Download Scholar III™ Heat Pumps & Air Conditioners (CSI 15740)

Transcript