Download GHM4, GHM6, & GHM8

Transcript

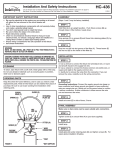

Operations & Service Manual GHM4, GHM6, & GHM8 Model: GHM4 Model: GHM6 Model: GHM8 Giles Enterprises, Inc. 2750 Gunter Park Drive West • Montgomery, AL 36109 USA Fax: (334) 272-3561 • Internet: www.gilesent.com Service Hotline (Toll Free): 1-800-554-4537 (USA & Canada Only) Form No. 60329 (Release date: 9/00)(Revision Date: 10/01/03)(Rev B) LIMITED WARRANTY • Subject to the terms and conditions of this Limited Warranty as herein stated, all Giles Enterprises, Inc., Foodservice Equipment and parts purchased new from an authorized Giles Enterprises, Inc., representative are warranted as to defects in material or workmanship for a period of 12 months from the date of installation, provided, however, that with regard to labor costs in connection with this warranty, see below. All installations must be made by a qualified installing agency in accordance with all applicable codes and/or regulations in the jurisdiction in which installed. Limited warranty coverage is extended to the original owner only and is void if the unit is resold. • During the Limited Warranty period, Giles Enterprises, Inc. will replace or recondition, at its factory, any part or parts of this unit which Giles Enterprises, Inc. inspectors judge defective, provided the unit has been subjected to normal usage, properly installed, operated and serviced. This Limited Warranty does not cover cosmetic damage, and damage due to acts of God, accident, misuse, alteration, negligence, abuse of the Giles Foodservice Equipment or the use of unorthodox repair methods. All parts replaced under this Limited Warranty carry only the unexpired term of this Limited Warranty. Limited Warranty service may be furnished only by an authorized Giles Enterprises, Inc., representative. • If Limited Warranty service is requested, Giles Enterprises, Inc., will send factory-authorized service representatives to repair, recondition, replace or inspect units of its manufacture with such labor being rendered without cost to owner for ninety (90) days from the date of installation. Otherwise, service, including labor and transportation charges or other expenses, in connection with the removal or installation of any part or parts supplied under this Limited Warranty, are specified on the original sales contract between the purchaser and the authorized Giles Enterprises, Inc., representative. • Giles Enterprises, Inc. reserves the right to change or improve its equipment and parts in any way, without obligation to alter such equipment or parts previously manufactured. • Giles Enterprises, Inc. makes no further warranties, express or implied including implied warranties of merchantability or fitness for a particular purpose, and has no other obligation or liability not specifically stated herein. • Repair or replacement as provided under this limited warranty is the exclusive remedy. Giles Enterprises, Inc., shall not be liable for any incidental or consequential damages for breach of any express or implied warranty on this product, except to the extent prohibited by applicable law. Any implied warranty of merchantability or fitness for a particular purpose on this product is limited in duration to the duration of this limited warranty. • Used Giles Enterprises, Inc., Foodservice Equipment or parts or Giles Enterprises, Inc., Foodservice Equipment or parts not purchased from an authorized Giles Enterprises, Inc., representative, carry no warranties, express or implied. Table Of Contents Safety Model: GHM4, GHM6, & GHM8 ........................................................v Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v Specific Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1-1. 1-2. 1-3. 1-4. 1-4.1. 1-4.2. 1-4.3. 1-4.4. 1-4.5. 1-4.6. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Standard Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Overall Dimensions for GHM4, GHM6, GHM8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Basic Steam Pan Configurations for GHM4, GHM6, GHM8 . . . . . . . . . . . . . . . . . . . . . . . . . 3 Profile of Base Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Regulatory Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Number of Pan Wells, Heated Zones, and Lighted Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2-01. 2-02. 2-03. 2-04. 2-05. 2-06. 2-07. 2-08. 2-08.1 2-09. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Counter Top Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Base Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Installation of the Glass (Full Serve) and Heat Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Installation of the Glass (Self Serve) and Heat Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Electrical Connections Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Ventilation of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 3. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 3-01. 3-02. 3-03. Back and Side View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Accessories (Included) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Accessories (Not Included). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4. Unit Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 4-1. 4-2. 4-3. 4-4. 4-5. 4-6. 4-7. Installation of Pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Setting and Adjusting Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Setting and Adjusting Heat Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Cutting Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Cutting Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Normal Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Emergency Shut-Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 iii Model: GHM4, GHM6, & GHM8 Table Of Contents 5. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 6. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 7. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 7–1. 7-2. 7-3. 7-4. 7-5. Parts Ordering and Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Control Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Element Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 Glass and Cutting Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Heat Lamp Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 8. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 8-01. 8-02. 8-03. 8-04. 8-05. 8-06. 8-07. 8-08. 8-09. 8-10. 8-11. 8-12. Wiring Wiring Wiring Wiring Wiring Wiring Wiring Wiring Wiring Wiring Wiring Wiring iv Diagram Diagram Diagram Diagram Diagram Diagram Diagram Diagram Diagram Diagram Diagram Diagram GHM4 GHM4 GHM4 GHM6 GHM6 GHM6 GHM6 GHM6 GHM6 GHM8 GHM8 GHM8 208-240/60/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 220/50/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 380/50/3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 FULL SERVE 208-240/60/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 SELF SERVE 208-240/60/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 FULL SERVE 220/50/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 FULL SERVE 380/50/3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 SELF SERVE 220/50/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 SELF SERVE 380/50/3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 FULL SERVE 208-240/60/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 SELF SERVE 208-240/60/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 FULL SERVE 380/50/3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Safety Model: GHM4, GHM6, & GHM8 Safety Safety Overview The instructions contained in this manual have been prepared to aid you in learning the proper procedures for installing and servicing your new unit. Throughout this manual, safety precautions are identified through the use of the safety alert symbol and three signal words: DANGER, WARNING, and CAUTION. All safety alert information precedes the step(s) to which they apply. Suggested, recommended, or other noteworthy information is identified through the use of NOTES. Additionally, certain words are used to indicate a specific meaning or to add emphasis. The following words are used as indicated throughout the manual: Shall: understood to be mandatory. Should: understood to be advisory. May: understood to be permissive. Will: indicates a future event/condition to occur. ! or ! (Safety Alert Symbol) Used in conjunction with signal words (DANGER, WARNING, or CAUTION) to alert you of potential personal injury hazards, immediately preceding precautionary measures that pertain to subsequent step(s). Obey all safety messages that follow this symbol to avoid possible injury or death. Failure to adhere to safety precautions identified by the safety alert symbol may also void the warranty. ! DANGER • Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. ! WARNING • Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. ! CAUTION • Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. Also used to alert against unsafe practices. CAUTION • When used without the safety alert symbol, CAUTION indicates a potentially hazardous situation which, if not avoided, may result in equipment/property damage, and void the warranty. NOTE: • Identifies suggested, recommended, or other noteworthy information. v Model: GHM4, GHM6, & GHM8 Safety Specific Safety Precautions For your safety, please observe the following precautions when operating or servicing your Giles equipment. Read the following important safety information to avoid personal injury and/or damage to the equipment. ! DANGER • Turn off the unit and unplug the power cord before cleaning or performing maintenance. • DO NOT ADD WATER OR OTHER LIQUID SOLUTIONS! The food well area is not sealed and liquids will leak onto the heating Elements underneath. • DO NOT hose down the unit’s interior or exterior with water. • Failure to comply with these DANGER notices will result in death or serious injury, equipment/property damage, and void the warranty. ! WARNING • Consult a qualified electrician to ensure that: •• all electrical specifications and codes are met. •• circuit breakers and wiring are of sufficient rating and gauge. • The unit must be properly grounded and all electrical specifications must be met during installation. • Improper installation, adjustment, alteration, service or maintenance could result in death or serious injury, equipment/property damage, and void the warranty. • DO NOT use or store gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance! • Failure to comply with WARNING notices could result in death or serious injury and equipment/property damage and void the warranty. ! CAUTION • The unit must remain in the upright (vertical) position. • Exercise care when removing the wooden crate from around the unit. • DO NOT operate the unit unless you fully understand the components and their intended function (see Section 3). • The unit and its parts are HOT! Temperatures inside the unit may exceed 150°F (65.5°C). Exercise caution when operating, loading/unloading food, cleaning or servicing. Wearing of thermal oven mitts is recommended. • Failure to comply with CAUTION notices may result in minor or moderate injury, equipment/property damage, and void the warranty. vi Safety Model: GHM4, GHM6, & GHM8 ! CAUTION • Food products must be maintained at a temperature of 150°F (65.5°C) minimum or in accordance with local or state health regulations. • The unit must be adequately and properly grounded. Improper grounding may result in electrical shock. Always refer to your local electrical code to ensure proper grounding of this or any other electrical equipment. Always consult with an electrician or other qualified service person to ensure breakers and wiring are of sufficient rating and gauge for the equipment being operated. • Units are available from the factory wired for various voltage, phase and hertz. Check the rating plate on the side of the unit to determine the correct power supply. • Ensure the unit is positioned in a secure, safe location • Consult an electrician to ensure all electrical specifications have been met and the unit is properly grounded. The wiring diagrams contained in this manual should aid your electrician in the installation of your unit. • Allow the unit to cool down a minimum of 15 minutes before cleaning or servicing. CAUTION • The electronic components of the Control Panel are impact-sensitive. Exercise care around the Control Panel to maintain proper operation. • DO NOT install the unit next to combustible walls and materials. Failure to maintain safe distances may result in fire. • During cleaning of the unit •• DO NOT steam clean. •• DO NOT use products containing chlorine. •• DO NOT use abrasive products, steel wool or scouring pads. •• DO NOT use oven cleaner. • Failure to comply with these CAUTION notices may result in equipment/property damage and void the warranty. • DO NOT Modify, Alter or Add Attachments to This Equipment! NOTE: • If the crate is damaged upon receipt, immediately inspect the unit and notify the carrier of any damage to the unit. • To aid the electrician, an electrical wiring diagram is contained in this manual. Refer to the wiring diagram during installation or servicing. • Comply with all appropriate state and/or local heath regulations regarding the cleaning and sanitation of equipment. vii Model: GHM4, GHM6, & GHM8 Notes: viii Safety Introduction 1. Model: GHM4, GHM6, & GHM8 Introduction Congratulations on the purchase of your new Giles Heated Merchandiser (GHM) manufactured by Giles Enterprises, Inc., Montgomery, Alabama (USA), hereafter referred to as "Giles". Three different models (GHM 4, GHM 6, and GHM 8) are available, each as a countertop model or with an optional base. Proper care and maintenance of this unit will ensure years of trouble-free service. The GHM has been developed with flexibility in mind, designed to maximize menu selections while keeping the food products fresh and maintaining them at the proper serving temperature, just waiting for your customers to enjoy. Deli personnel have the option of displaying fresh prepared foods for full service, or placing prepackaged foods for customer self-service. In either case, the products are highly visible and appealing to the customer. To help protect your investment in this equipment, we recommend taking a few moments to familiarize yourself with the installation, cleaning and maintenance procedures contained in this manual. Read these instructions before installation and use. Adherence to these recommended procedures minimizes the potential for costly "down-time" and equipment repairs. Please retain this manual for future reference. 1-1. Construction All of the unit’s exterior parts and the pan well are constructed of stainless steel. The unit is equipped with a tempered European-style glass cover and utilizes safety coated heat lamps. 1-2. Standard Features Temperature -Adjustable, variable control of well heaters, indicator lights verify unit operation. Lighting -Adjustable, variable control of heat lamp output. European-Style Glass -Allows maximum visibility of the product. Gas lift springs will hold the glass in the open position for easy cleaning. Fold Down Cutting Board -Folding and removable cutting board. 1-3. Optional Features Self-serve -Available in a 24” section on the left or right side of the unit. Allows the customer to remove product from the unit. Glass color -Glass is available in clear, or mirror. Base -Five bases are available: High Profile, Low Profile, Super Low Profile, Pedestal Profile, and Standard. 1 Model: GHM4, GHM6, & GHM8 1-4. Specifications 1-4.1. Overall Dimensions for GHM4, GHM6, GHM8 INCHES [MILLIMETERS] 2 Introduction Introduction Model: GHM4, GHM6, & GHM8 1-4.2. Basic Steam Pan Configurations for GHM4, GHM6, GHM8 INCHES [MILLIMETERS] 3 Model: GHM4, GHM6, & GHM8 Introduction 1-4.3. Profile of Base Options SLP-4, 6, or 8 PP-4, 6, or 8 LP-4, 6, or 8 FL-4, 6, or 8 HP-4, 6, or 8 INCHES [MILLIMETERS] 4 Introduction Model: GHM4, GHM6, & GHM8 1-4.4. Regulatory Listings UL (US and Canada) UL Sanitation CE 1-4.5. Unit Weights Weights Model Uncrated w/o product or pans Crated lb kg lb kg GHM4 489 221.8 277 125.6 GHM6 621 281.7 390 177 GHM8 812 368.3 503 229 1-4.6. Number of Pan Wells, Heated Zones, and Lighted Zones Heated Zones Lighting Zones Total Lights Model Pan Wells GHM4 3 2 2 6 GHM6 Full Serve 5 3 3 10 GHM6 Self Serve 5 3 3 9 GHM8 Full Serve 7 4 4 14 GHM8 Self Serve 7 4 4 13 5 Model: GHM4, GHM6, & GHM8 Notes: 6 Introduction Installation Model: GHM4, GHM6, & GHM8 2. Installation This section provides a summary of the procedures necessary for proper installation of your unit. To prevent personal injury or equipment damage, please ensure the following steps are taken. 2-01. Location CAUTION • DO NOT MODIFY, ALTER OR ADD ATTACHMENTS TO THIS EQUIPMENT 1. Keep the appliance and surrounding area free and clear from combustible materials. Always keep a minimum clear distance of 6 inches [152.4 mm] in front of the unit. 2. Please retain this manual for future reference. 3. Please note wiring diagrams for this appliance are located in the rear of this manual. Ensure the wiring diagram corresponds with the model being operated. 4. Please ensure this appliance is electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA NO. 70-1999. 5. Please provide adequate room for servicing and proper operation of this appliance. Also, provide adequate ventilation in the operating area where necessary. 6. Always consult with an electrician or other qualified service person prior to installation. 7. Ensure voltage and amperage supplied to the unit are as specified on the unit’s rating plate. 8. Make sure this unit is in a secure position and will not move. The above steps will help to ensure safe and proper installation of your unit. If you have any questions concerning these procedures, contact your local Giles distributor or other qualified service person. 7 Model: GHM4, GHM6, & GHM8 Installation 2-02. Unpacking Your unit may arrive enclosed by a wooden crate. The unit is secured to a wooden platform by means of hightensile strength strapping. ! CAUTION • Exercise care when lifting or moving the unit. • Exercise care when removing the wooden crate from around the unit. • Failure to comply with these CAUTION notices may result in minor or moderate injury, equipment/property damage, and void the warranty. NOTE: • If the crate is damaged, immediately inspect the unit and notify the carrier of any damage to the unit. 1. Carefully cut and remove the plastic shipping wrap and the strapping mentioned above. 2. Use pliers to loosen wire hooks which secure the wooden crate around the unit. Remove the wooden crate. 3. Carefully remove the unit from the shipping platform. Your new unit is extremely heavy, see Section 1.4.5 Unit Weights. Great care should be taken in lifting or moving the unit to prevent personal injury or equipment damage. 2-03. Counter Top Installation 1. There are (2) supplied Leg Mount Plates, attach (1) Leg Mount Plate to each leg. Upper Leg Leg Mount Foot 2. 8 Fasten (4) supplied adjustable legs, (2) with Leg Mount Plates which should be diagonal from one another, to the bottom of the unit. Installation Model: GHM4, GHM6, & GHM8 ! CAUTION • Exercise care when lifting or moving the unit. • Ensure the counter and counter-top can support the weight of the unit. See 1-4.5 Unit Weights. 3. Place the unit on the counter-top. 4. Using the Adjustable legs, level the unit. 5. Secure the unit to the counter-top by fastening the Leg Mounts to the counter-top with appropriate screws (not supplied). Rear Leg Mount Front Leg Mount (3) Screws (supplied by customer) each Leg Mount Plate 9 Model: GHM4, GHM6, & GHM8 Installation 2-04. Base Installation 1. Prior to installing the GHM on the base 1 the unit must be leveled. Leveling of the base 1 can be accomplished by adjusting the leveling feet 2 that are included with the base 1 . Confirm the level of the base 1 by measuring both the length and width of the base with a 24” level. 1 2 2. The Giles GHM units come with mounting screws to attach the unit to the base.These screws must be used in the attachment of the case to the base. These screws are designed to meet sanitation regulations by being the correct length to not allow any exposed threads. 3. Non-specified screws,if used, must conform to applicable health and sanitation standards. 10 Installation Model: GHM4, GHM6, & GHM8 4. Once the unit has been installed on the base the seams between the base and the unit must be caulked. This must be done internally and externally. A food grade caulk must be used to perform the sealed joint. 5. Depending on local and state health codes the base of the GHM must be sealed to the floor to eliminate harborage of vermin. This is the responsibility of the installer to perform this task. It can be completed by using a food grade sealant or stainless steel flashing attached to the base and then sealed to the floor with food grade sealant. 6. If flashing is to be used it must be attached with stainless steel self-tapping screws or bonding double sided adhesive. Other methods of fastening could potentially harm the painted surfaces causing rust or other non-conformance issues with applicable health or sanitation codes. 7. In locations where flashing is not permitted, the base can be mounted on 6” legs to comply with local codes. 11 Model: GHM4, GHM6, & GHM8 Installation 2-05. Installation of the Glass (Full Serve) and Heat Lamps 1 2 1. Install Rear Sliding Glass 1 . 2. Install Side Glass 2 and 3 . 3. Install Heat Lamps 4 . 12 4 3 Installation Model: GHM4, GHM6, & GHM8 2-06. Installation of the Glass (Self Serve) and Heat Lamps 2 6 7 5 4 3 1. Install Middle Glass Support 1 . 2. Install Middle Glass 2 . 3. Install Sneeze Guard Glass 3 . 4. Install Side Glass 4 and 5 . 5. Install Heat Lamps 6 . 6. Install Rear Sliding Glass 7 . 1 13 Model: GHM4, GHM6, & GHM8 Installation 2-07. Electrical Requirements ! CAUTION • The unit must be adequately and properly grounded. Improper grounding may result in electrical shock. Always refer to your local electrical code to ensure proper grounding of this or any other electrical equipment. Always consult with an electrician or other qualified service person to ensure breakers and wiring are of sufficient rating and gauge for the equipment being operated. Units are available from the factory in the voltages and phases listed below. Check the rating plate on the side of the unit to determine the correct power supply. Table 2-07. Electrical Breaker Requirements 14 Model Voltage Hz Phase Watts GHM4 208 60 1 GHM4 240 60 GHM4 220 GHM4 AMPS L1 L2 L3 Breaker Required 2495 12 12 --- 15 1 3120 13 13 --- 20 50 1 2860 13 13 --- 20 380 50 3 2990 4.5 4.5 4.5 10 GHM4 415 50 3 3120 5 5 5 10 GHM6 208 60 1 4556 17 17 --- 30 GHM6 240 60 1 6065 20 20 --- 30 GHM6 220 50 1 5560 20 20 --- 30 GHM6 380 50 3 5810 7.5 7.5 7.5 10 GHM6 415 50 3 6065 8.5 8.5 8.5 10 GHM8 208 60 1 6380 31 31 --- 35 GHM8 240 60 1 8490 35 35 --- 50 GHM8 220 50 1 7770 35 35 --- 50 GHM8 380 50 3 8140 10.5 10.5 10.5 15 GHM8 415 50 3 8630 12 12 12 15 Installation Model: GHM4, GHM6, & GHM8 2-08. Electrical Connections 1. Install appropriate Circuit Breakers in Main Breaker Box. See Table 2-07. 2. Connect appropriate size Power Cable wire to the Main Breaker. Allow enough Cable so the unit can be moved for cleaning and servicing. 3. Remove the Service Box Cover. See Figure 2-06.1. 4. Install the supplied Power Cable Strain Relief to the unit. 5. Run the Power Cable through the Strain Relief and then tighten the Strain Relief. 6. Connect appropriate Power Cable wires to the unit’s Terminal Blocks. 7. Reinstall Service Box Cover. 8. Turn Main Breaker on. 9. Rotate each Temperature Knob and verify that the unit is heating. 10. Rotate each Lighting Knob and verify the the lights turn on. 2-08.1 Electrical Connections Diagram Power Cable Strain Relief Power cable Service Box Cover Terminal Blocks Power Cable Wires from Main Breaker 15 Model: GHM4, GHM6, & GHM8 Installation 2-09. Ventilation of the Unit NOTE: • Guidelines for proper ventilation system requirements may differ from location to location. Always consult with local authorities to ensure compliance. 16 Overview Model: GHM4, GHM6, & GHM8 3. Overview The following section provides a brief overview of the components, functions, and accessories of the unit. Please review this section carefully before proceeding any further. Model: GHM4 Model: GHM6 Model: GHM8 17 Model: GHM4, GHM6, & GHM8 Overview 3-01. Back and Side View 7 8 6 1 18 2 3 4 5 Overview Model: GHM4, GHM6, & GHM8 3-01. Back and Side View Item 1 2 3 Description Function Fuse Holder (GHM6 and GHM8 Only) Holds the 15 Amp fuse that completes the electrical circuit to the heating lamps. There are two of these on each unit. Indicator Light The Red Indicator light gives a visual indication of whether or not the Elements are heating. The light is on (illuminated) while the Elements are heating. The Indicator Light goes out once the power has been removed from the Elements and they are no longer heating. There is an Indicator Light for each Thermostat. Thermostat The SET TEMPERATURE knob is used to adjust the Thermostat and achieve the desired temperature output of the heating Elements. Other than OFF, settings range from 0 to 10, incrementally (0 is the coolest setting and the 10 is the hottest). The number of Thermostats vary with the GHM models. 4 Rheostat The variable range LIGHTING knob is used to adjust the Rheostat and achieve the desired brightness of the heat Lamps. The knob is rotated clockwise for more lighting and counterclockwise for less. The number of Rheostats vary by GHM model. 5 Service Entrance The SERVICE ENTRANCE BOX cover provides access to the electrical connections from external power sources. 6 Lamps (Typical) These Teflon coated 150 watt Lamps are located underneath the hood of the display case, and provide lighting, as well as additional heat. The number of Lamps required varies with different GHM models. Use of high wattage lamps could damage unit. 7 European Style Glass This attractive glass cover provides maximum visibility of the products being displayed inside the case. It is attached with two hinges containing gas lift springs that make it easy to raise for cleaning. 8 Cutting Board The cutting board may be folded up or down and is easily removable. It is used for a convenient place to prepare food. 19 Model: GHM4, GHM6, & GHM8 3-02. Overview Accessories (Included) Part / Part Number Description Function Pan Support Channel (Long) (2) -GHM4 (4) -GHM6 (6) -GHM8 Used to support Pans front to back. Giles P/N: 35788 Pan Support Channel (Short) (6) -GHM4 (15) -GHM6 (21) -GHM8 Used to support Pans left to right. Giles P/N: 35789 (4) Leg Used when installing the unit and placing the unit on a counter-top. Giles P/N: 46766 (1) Power Cord Strain Relief Giles P/N: 20350 20 Used when installing the unit to prevent strain on the power cord. Overview Model: GHM4, GHM6, & GHM8 3-02. Accessories (Included) Part / Part Number Description Function (2) Leg Mounting Plate Used when installing the unit to secure the unit to a counter-top Heat Lamp (6) -GHM4 (10) -GHM6 (14) -GHM8 Used to Light and Heat the product (2) Self Serve Tile Used in the Self Serve Area (Self Serve Model Only) Middle Glass Support Channel Used to support the middle glass used on the Self Serve Area (Self Serve Model Only) Giles P/N: 35533 Giles P/N: 25356 (130V) (60Hz units) Giles P/N: 20088 (230V) (50Hz units) Giles P/N: 66033 Giles P/N: 36006 21 Model: GHM4, GHM6, & GHM8 3-03. Overview Accessories (Not Included) Part / Part Number Description Function Steam Pan (Full size) Used for Cooking and Displaying food. Steam Pan (1/2 size) Used for Cooking and Displaying food. Giles P/N 76183 -2-1/2” DEEP Giles P/N 76184 -4” DEEP Giles P/N 76185 -2-1/2” DEEP Giles P/N 76186 -4” DEEP Steam Pan (1/3 size) Giles P/N 76188 -2-1/2” DEEP Giles P/N 76189 -4” DEEP 22 Used for Cooking and Displaying food. Overview Model: GHM4, GHM6, & GHM8 3-03. Accessories (Not Included) Part / Part Number Description Function Steam Pan Grate (Full size) Used to allow drainage on food. Steam Pan Grate (1/2 size) Used to allow drainage on food. Steam Pan Grate (1/3 size) Used to allow drainage on food. Giles P/N: 76207 Giles P/N: 76208 Giles P/N: 70165 23 Model: GHM4, GHM6, & GHM8 Notes: 24 Overview Operation Model: GHM4, GHM6, & GHM8 4. Unit Operation This section describes how to operate the unit. Model: GHM4 Model: GHM6 Model: GHM8 25 Model: GHM4, GHM6, & GHM8 Operation 4-1. Installation of Pans This section describes how to install the pan dividers and the warming pans. ! DANGER DO NOT ADD WATER OR OTHER LIQUID SOLUTIONS! The food well area is not sealed and liquids will leak onto the heating Elements underneath. ! CAUTION Before installing pan dividers and the warming pans. Ensure the Heat Lamps and Set Temperature knobs are in the OFF position see 4-6, Normal Shut-Down and the unit is cool. 1 2 3 4 1. Lift the Front Curved Glass 1 and/or Slide the Sliding Doors 2 open. 2. Install the Long Pan Support channels 3 at each Channel Placement angle 4 . 5 1 3. Install the Short Pan Support channels 5 between each of the Long Pan Support Channels 1 . (Continued on next page. 26 Operation 4-1. Model: GHM4, GHM6, & GHM8 Installation of Pans (Continued) 4. Install the Steam Pans in between the Long and Short Pan Support Channels. There are many pan configurations you may use; for some basic configurations see above. NOTE: Ensure there are NO gaps between Steam Pans. Any gaps will cause the unit to lose heat. 5. Close the Front Curved Glass and/or Slide the Sliding Doors closed. 27 Model: GHM4, GHM6, & GHM8 Operation 4-2. Setting and Adjusting Temperature This section describes how to adjust the temperature of warming area. 2 1 2 1 1. Ensure the Front Curved Glass is lowered, and in the closed position. 2. Ensure the Sliding Glass Doors are in the closed position. 3. Preheat the GHM by rotating all the SET TEMPERATURE knobs 1 to the number 8 setting; the Indicator Light 2 comes on. Allow the unit to preheat. 4. Once the Indicator Light(s) go out 2 , proceed to the next step. ! CAUTION • The GHM and its parts are HOT! Temperatures inside the unit may exceed 150°F (65.6°C). Exercise caution when operating, loading/unloading food, cleaning or servicing. Wearing of thermal oven mitts is recommended. 5. Wear appropriate hand protection and place hot food products into the Steam Pans of the GHM. (Continued on next page) 28 Operation 4-2. Model: GHM4, GHM6, & GHM8 Setting and Adjusting Temperature (Continued) 6. After placing the food products into the GHM, rotate the SET TEMPERATURE knob 1 to the number 6 setting. ! CAUTION • Food products must have a minimum internal temperature of 150ºF (66ºC) before placing in the GHM. 7. Periodically monitor the temperature of the products inside the GHM and adjust the SET TEMPERATURE knob 1 as necessary. NOTE: • Proper temperature range for holding food product depends on the amount and type of product contained in the GHM. • Periodically check that food products are being maintained at the proper temperature. • Temperature is manually adjusted using the SET TEMPERATURE knob settings, ranging from 10 (hottest) to 1 (coolest). 8. Follow local codes for hot holding temperatures. 29 Model: GHM4, GHM6, & GHM8 Operation 4-3. Setting and Adjusting Heat Lamps This section describes how to illuminate interior of the unit. 2 2 1 1 ! DANGER • DO NOT touch the Heat Lamps. The Heat Lamps are very hot and skin contact with the Heat Lamps may result in severe burns. 1. Rotate each Lighting knob 1 to adjust the Lighting intensity for each zone 2 . NOTE: • The unit uses 150 Watt Heat Lamps which not only illuminates the product, they also help heat the product. Monitor the product closely to ensure the top of the product is not overcooking or drying due to the Heat Lamps being set too high. 30 Operation Model: GHM4, GHM6, & GHM8 4-4. Cutting Board Installation This section illustrates how to install the cutting board to the unit. 4-5. Cutting Board Removal This section illustrates how to remove the cutting board from the unit. 31 Model: GHM4, GHM6, & GHM8 Operation 4-6. Normal Shut-Down This section explains the process of shutting the unit down. 3 1 1 2 3 2 1. Rotate all Heat Thermostats to the OFF 1 position, Indicator Lights 2 will go off. 2. Rotate all Lighting Rheostats to the OFF 3 position, all Display Lights will go off. 3. If required, turn off the unit’s circuit breaker in the main circuit breaker box to remove power to the unit. 4-7. Emergency Shut-Down In case of emergency, remove power to the unit by turning off the facility circuit breaker. 32 Cleaning Model: GHM4, GHM6, & GHM8 5. Cleaning This section describes the cleaning of the unit. Not only is it important that your food products be appealing to the customer, but the cleanliness of the unit in which they are displayed is also vital. Your new GHM is the show-case for your prepared food products and should be cleaned on a daily basis. ! DANGER • • DO NOT hose down the unit’s interior or exterior with water. Failure to comply with these DANGER notices will result in death or serious injury, equipment/property damage, and void the warranty. 1. Perform a Normal Shut-Down procedure as described in section 4-6, then allow unit to cool. 2. Rotate the Front Curved Glass to the open position. 3. Wear appropriate hand protection (if necessary from residual heat) and remove all Serving Pans and Pan Support Channels from the GHM. Place items in the sink for cleaning. 4. If needed, remove the Sliding Glass Door(s) by lifting upward until clear of lower track. Pivot the bottom of the door outward, then lower and remove. Place in an area suitable for cleaning. 5. Clean the interior and exterior of the GHM with soap and hot water. For difficult areas, use a mild degradable nontoxic degreaser (such as Clear Magic or Simple Green). 6. Clean the glass parts of the GHM with an ordinary window cleaner. 7. Polish all stainless areas outside the GHM with a good stainless polish. 8. Clean the Serving Pans and Pan Support Channels with soap and hot water. 9. Reinstall the Sliding Glass Door(s) by inserting top into the upper track. Pivot the bottom of the door inward and align with lower track. Slide the door down into the lower track. 10. Rotate the Front Glass to the closed position. 11. Reinstall Pan Support Channels and the Serving Pans. 33 Model: GHM4, GHM6, & GHM8 Notes: 34 Cleaning Troubleshooting GHM4, GHM6, & GHM8 6. Troubleshooting This section describes troubleshooting procedures for the unit. Refer to the wiring diagrams in Section 7 for more detailed analysis. ! DANGER • Electrical troubleshooting procedures should be done ONLY by qualified service personnel. Death or serious injury will result from contact with energized electrical components. • Failure to comply with these DANGER notices will result in death or serious injury, equipment/property damage, and void the warranty. Table 6-1. Troubleshooting Procedures Problem Probable Cause Repair Procedure Heat Lamps Not Working. A. Blown fuse. B. Incorrect wattage bulb. A. Replace fuse. B. Replace with correct wattage bulb. Unit not heating properly. A. Unit not plugged in. B. Unit not turned on. C. Heating elements defective. A. Plug unit in. B. Turn unit on. C. Call service technician to replace defective heating element. Unit will not turn on. A. Unit not plugged in. B. Fuse is defective. A. Plug unit in. B. Unplug unit from power source and replace fuse. Unit will not maintain food temperature of 150°F(65.6°C). A. Unit not plugged in. B. Unit not turned on. C. Heating Elements defective. A. Plug unit in. B. Turn unit on. C. Call service technician to place defective Heating Element. D. Insure food is at required temperature before placing into unit. D. Food not at proper temperature when place in unit. 35 Model: GHM4, GHM6, & GHM8 Notes: 36 Troubleshooting Parts List 7. Model: GHM4, GHM6, & GHM8 Parts List This section lists various parts that are available for replacement on the unit. 7–1. Parts Ordering and Service Information If you require assistance or need repairs, please contact your area developer for a service agency in your area. For further assistance, please contact the Giles Enterprises, Inc. factory at the following phone numbers: IN THE UNITED STATES, CANADA or MEXICO Please call 1-800-288-1555 during normal business hours, 8:00AM-5:00PM Central Time Zone; other than normal business hours, please call 1-800-288-1555, extension 314. IN ALL OTHERS COUNTRIES Please call 1-334-272-3528 during normal business hours, 8:00AM-5:00PM Central Time Zone; other than normal business hours, please call 1-334-272-3528 extension 314. INTERNET Please visit our website on the world wide web at: www.gilesent.com. The goal of the Giles team of professionals is to provide you with the highest quality of service and assistance. You can help us accomplish this by obtaining the following information and having it readily available when calling. The information is recorded on the Data Plate attached to the side of the unit. The area below may be helpful in recording information for use as a quick reference. Model Number: ______________________________________ Serial Number: ______________________________________ Phase: ___________________________________________ Voltage: ___________________________________________ Nature of Problem: __________________________________ 37 Model: GHM4, GHM6, & GHM8 Parts List 7-2. Control Panel Assembly 1 2 3 4 7 5 8 6 38 9 Parts List Model: GHM4, GHM6, & GHM8 7-2. Control Panel Assembly Item No. Part No. Qty. 1 21950 2 GHM6 2 GHM8 2 GHM6 1 2 21900 2 3 Model Description GHM4 3 3 GHM6 3 4 GHM8 2 GHM4 4 3 GHM6 4 4 GHM8 2 GHM4 5 3 GHM6 5 4 GHM8 2 GHM4 6 3 GHM6 6 4 GHM8 2 GHM4 7 3 GHM6 7 4 GHM8 2 GHM4 8 3 GHM6 8 4 GHM8 1 ALL 5 6 7 8 9 FUSE, 15AMP, SC-15 GHM8 2 4 HOLDER,FUSE,300V, 15A,SC 0 TO 15 22300 40777 20025 23701 40780 23702 36329 LIGHT, PILOT, 250V, ROUND, RED KNOB, THERMOSTAT, NO DIAL PLATE PLATE, KNOB DIAL 1-10, GHM THERMOSTAT, 60-250 DEG, 208-240V, GHM KNOB, RHEOSTAT VARIABLE GHM RHEOSTAT, LAMP, 120V PLATE, INSPECTION, (TERMINAL BLOCK COVER) 39 Model: GHM4, GHM6, & GHM8 Parts List 7-3. Element Assembly 2 3 4 1 40 Parts List Model: GHM4, GHM6, & GHM8 7-3. Element Assembly Item No. Part No. Qty. 1 20039 1 ALL STRAP, 3/8" TUBE 2 38901 1 60Hz TERMINAL BLOCK ASSY., 60Hz 2 37655 1 50Hz 1ø TERMINAL BLOCK ASSY., 50Hz, 1ø 2 37762 1 50Hz 3ø TERMINAL BLOCK ASSY., 50Hz, 3ø 3 25352 3 GHM4 3 5 GHM6 3 7 GHM8 3 GHM4 4 5 GHM6 4 7 GHM8 4 36009 Model Description ELEMENT, ROUND, 208/240V PLATE, HEAT DEFLECTION 41 Model: GHM4, GHM6, & GHM8 Parts List 7-4. Glass and Cutting Board Assembly 4 3 2 1 8 7 5 OR 9 5 6 42 Parts List Model: GHM4, GHM6, & GHM8 7-4. Glass and Cutting Board Assembly Item No. Part No. Qty. 1 40184 2 --- 4 GHM8 1 Model Description BRACKET, DROP SHELF, GHM 2 36142 1 GHM4 3 WELL, WORK SHELF, ASSY. 2 36131 1 GHM6 5 WELL WORK SHELF, ASSY 2 36123 1 GHM8 4 WELL WORK SHELF, ASSY 2 36122 1 GHM8 3 WELL WORK SHELF, ASSY 3 40287 1 GHM4 DOOR, LEFT, CLEAR 3 40369 1 GHM4 DOOR, LEFT, MIRROR 3 70432 1 GHM6 DOOR, LEFT, CLEAR 3 70449 1 GHM6 DOOR, LEFT, MIRROR 3 40207 1 GHM8 DOOR, LEFT, CLEAR 3 70446 1 GHM8 DOOR, LEFT, MIRROR 4 40286 1 GHM4 DOOR, RIGHT, CLEAR 4 40371 1 GHM4 DOOR, RIGHT, MIRROR 4 70149 1 GHM6 DOOR, RIGHT, CLEAR 4 70448 1 GHM6 DOOR, RIGHT, MIRROR 4 40208 1 GHM8 DOOR, RIGHT, CLEAR 4 70447 1 GHM8 DOOR, RIGHT, MIRROR 5 40182 2 ALL SIDE, GLASS, CLEAR 5 40442 1 ALL SIDE, GLASS, MIRROR, LEFT 6 40183 1 ALL S/S MIDDLE, GLASS, CLEAR 7 40178 1 ALL S/S GLASS, 2' SELF SERVE 8 40479 1 GHM4 S/S GLASS, 4' SELF SERVE 8 45156 1 GHM4 FUL GLASS, 4' FULL SERVE 8 45156 1 GHM6 S/S GLASS, 6' SELF SERVE 8 40179 1 GHM6 FUL GLASS, 6' FULL SERVE 8 40179 1 GHM8 S/S GLASS, 6' SELF SERVE 8 40514 1 GHM8 FUL GLASS, 51” FULL SERVE 8 45156 1 GHM8 FUL GLASS, 4’ FULL SERVE 9 40374 1 ALL SIDE, GLASS, MIRROR, RIGHT 43 Model: GHM4, GHM6, & GHM8 Parts List 7-5. Heat Lamp Assembly 2 1 44 Parts List Model: GHM4, GHM6, & GHM8 7-5. Heat Lamp Assembly Item No. Part No. Qty. Model Description 1 25356 6 GHM4 LAMP, 150W, 130V, TEFLON COATED, (60Hz Modes) 1 20088 6 GHM4 LAMP, 150W, 230V, TEFLON COATED, (50Hz Modes) 1 25356 8 GHM6 LAMP, 150W, 130V, TEFLON COATED, (60Hz Modes) 1 20088 8 GHM6 LAMP, 150W, 230V, TEFLON COATED, (50Hz Modes) 1 25356 10 GHM8 LAMP, 150W, 130V, TEFLON COATED, (60Hz Modes) 1 20088 10 GHM8 LAMP, 150W, 230V, TEFLON COATED, (50Hz Modes) 2 25355 6 GHM4 BASE, GHM LAMP, CERAMIC 2 8 GHM6 2 10 GHM8 45 Model: GHM4, GHM6, & GHM8 Notes: 46 Parts List Wiring Diagram Model: GHM4, GHM6, & GHM8 8. Wiring Diagram The following section contains Wiring Diagrams for the various units. Please check the Serial Plate on the side of the unit, as shown below, for the units Model Name, Voltage, Hertz, and Phase. Serial Plate 47 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-01. Wiring Diagram GHM4 208-240/60/1 WIRING DIAGRAM P/N: 36376-D 48 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-01. Parts List for Wiring Diagram GHM4 208-240/60/1 Item 01 02 03 04 05 06 07 08 09 10 11 12 Part No. 20319 23701 23702 22300 25352 25355 25356 25275 20320 20321 20322 25300 Qty. 3 2 2 2 3 6 6 4 3 2 1 3 Description TERMINAL BLOCK,50 AMP,AWG 8-24 THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP, 150W, 130V, TEFLON COATED, GHM WIRENUT, IDEAL BLUE TERMINAL BLOCK,GROUNDING,AWG 8-24 TERMINAL MARKING STRIP,UK6N BRIDGE,10 POSITION W/SCREWS WIRENUT, 73B IDEAL ORANGE 49 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-02. Wiring Diagram GHM4 220/50/1 WIRING DIAGRAM P/N: 37109-C 50 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-02. Parts List for Wiring Diagram GHM4 220/50/1 Item 01 02 03 04 05 06 07 08 09 10 11 Part No. 20181 23701 23702 22300 25352 25355 20088 25275 20182 20183 20184 Qty. 3 2 2 2 3 6 6 2 3 2 1 Description BLOCK,TERMINAL,24-10GA,30 AMP THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, IDEAL BLUE BLOCK UNIVERSAL GROUND TERMINAL 20-10GA MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N 51 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-03. Wiring Diagram GHM4 380/50/3 WIRING DIAGRAM P/N: 37568-C 52 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-03. Parts List for Wiring Diagram GHM4 380/50/3 Item 01 02 03 04 05 06 07 08 09 10 11 12 Part No. 20181 23701 23702 22300 25352 25355 20088 25300 20182 20183 20184 21950 Qty. 6 2 2 2 3 6 6 2 2 2 1 1 Description BLOCK,TERMINAL,24-10GA,30 AMP THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, 73B IDEAL ORANGE BLOCK UNIVERSAL GROUND TERMINAL 20-10GA MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N HOLDER, FUSE, 300V, 15A, SC 0 TO 15 53 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-04. Wiring Diagram GHM6 FULL SERVE 208-240/60/1 WIRING DIAGRAM P/N: 36375-C 54 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-04. Parts List for Wiring Diagram GHM6 FULL SERVE 208-240/60/1 Item 01 02 03 04 05 06 07 08 09 10 11 12 13 Part No. 20319 23701 23702 22300 25352 25355 25356 25275 21950 20320 20321 20322 25300 Qty. 6 3 3 3 5 10 10 8 2 2 2 1 4 Description TERMINAL BLOCK,50 AMP,AWG 8-24 THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP, 150W, 130V, TEFLON COATED, GHM WIRENUT, IDEAL BLUE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 TERMINAL BLOCK,GROUNDING,AWG 8-24 TERMINAL MARKING STRIP,UK6N BRIDGE,10 POSITION W/SCREWS WIRENUT, 73B IDEAL ORANGE 55 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-05. Wiring Diagram GHM6 SELF SERVE 208-240/60/1 WIRING DIAGRAM P/N: 39073-B 56 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-05. Parts List for Wiring Diagram GHM6 SELF SERVE 208-240/60/1 Item 01 02 03 04 05 06 07 08 09 10 11 12 13 Part No. 20319 23701 23702 22300 25352 25355 25356 25275 21950 20320 20321 20322 25300 Qty. 6 3 3 3 5 9 9 8 2 2 2 1 4 Description TERMINAL BLOCK,50 AMP,AWG 8-24 THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP, 150W, 130V, TEFLON COATED, GHM WIRENUT, IDEAL BLUE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 TERMINAL BLOCK,GROUNDING,AWG 8-24 TERMINAL MARKING STRIP,UK6N BRIDGE,10 POSITION W/SCREWS WIRENUT, 73B IDEAL ORANGE 57 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-06. Wiring Diagram GHM6 FULL SERVE 220/50/1 WIRING DIAGRAM P/N: 37110-C 58 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-06. Parts List for Wiring Diagram GHM6 FULL SERVE 220/50/1 Item 01 02 03 04 05 06 07 08 09 10 11 12 Part No. 20181 23701 23702 22300 25352 25355 20088 25300 21950 20182 20183 20184 Qty. 3 3 3 3 5 10 10 3 2 3 2 1 Description BLOCK,TERMINAL,24-10GA,30 AMP THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, 73B IDEAL ORANGE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 BLOCK UNIVERSAL GROUND TERMINAL 20-10GA MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N 59 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-07. Wiring Diagram GHM6 FULL SERVE 380/50/3 WIRING DIAGRAM P/N: 37569-C 60 Wiring Diagram 8-07. Item 01 02 03 04 05 06 07 08 09 10 11 12 Model: GHM4, GHM6, & GHM8 Parts List for Wiring Diagram GHM6 FULL SERVE 380/50/3 Part No. 20181 20182 23701 23702 22300 25352 25355 20088 25300 21950 20183 20184 Qty. 6 2 4 4 4 5 10 10 4 2 2 1 Description BLOCK,TERMINAL,24-10GA,30 AMP BLOCK UNIVERSAL GROUND TERMINAL 20-10GA THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, 73B IDEAL ORANGE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N 61 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-08. Wiring Diagram GHM6 SELF SERVE 220/50/1 WIRING DIAGRAM P/N: 39236-A 62 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-08. Parts List for Wiring Diagram GHM6 SELF SERVE 220/50/1 Item 01 02 03 04 05 06 07 08 09 10 11 12 Part No. 20181 23701 23702 22300 25352 25355 20088 25300 21950 20182 20183 20184 Qty. 3 3 3 3 5 9 9 3 2 3 2 1 Description BLOCK,TERMINAL,24-10GA,30 AMP THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, 73B IDEAL ORANGE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 BLOCK UNIVERSAL GROUND TERMINAL 20-10GA MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N 63 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-09. Wiring Diagram GHM6 SELF SERVE 380/50/3 WIRING DIAGRAM P/N: 39235-A 64 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-09. Parts List for Wiring Diagram GHM6 SELF SERVE 380/50/3 Item 01 02 03 04 05 06 07 08 09 10 11 12 Part No. 20181 20182 23701 23702 22300 25352 25355 20088 25300 21950 20183 20184 Qty. 6 2 4 4 4 5 9 9 4 2 2 1 Description BLOCK,TERMINAL,24-10GA,30 AMP BLOCK UNIVERSAL GROUND TERMINAL 20-10GA THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, 73B IDEAL ORANGE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N 65 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-10. Wiring Diagram GHM8 FULL SERVE 208-240/60/1 WIRING DIAGRAM P/N: 35695-E 66 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-10. Parts List for Wiring Diagram GHM8 FULL SERVE 208-240/60/1 Item 01 02 03 04 05 06 07 08 09 10 11 12 13 Part No. 20319 23701 23702 22300 25352 25355 25356 25275 21950 20320 20321 20322 25300 Qty. 6 3 3 3 5 10 10 9 2 2 2 1 6 Description TERMINAL BLOCK,50 AMP,AWG 8-24 THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP, 150W, 130V, TEFLON COATED, GHM WIRENUT, IDEAL BLUE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 TERMINAL BLOCK,GROUNDING,AWG 8-24 TERMINAL MARKING STRIP,UK6N BRIDGE,10 POSITION W/SCREWS WIRENUT, 73B IDEAL ORANGE 67 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-11. Wiring Diagram GHM8 SELF SERVE 208-240/60/1 WIRING DIAGRAM P/N: 39072-B 68 Wiring Diagram 8-11. Item 01 02 03 04 05 06 07 08 09 10 11 12 13 Model: GHM4, GHM6, & GHM8 Parts List for Wiring Diagram GHM8 SELF SERVE 208-240/60/1 Part No. 20319 23701 23702 22300 25352 25355 25356 25275 21950 20320 20321 20322 25300 Qty. 6 3 3 3 5 10 10 9 2 2 2 1 6 Description TERMINAL BLOCK,50 AMP,AWG 8-24 THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP, 150W, 130V, TEFLON COATED, GHM WIRENUT, IDEAL BLUE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 TERMINAL BLOCK,GROUNDING,AWG 8-24 TERMINAL MARKING STRIP,UK6N BRIDGE,10 POSITION W/SCREWS WIRENUT, 73B IDEAL ORANGE 69 Model: GHM4, GHM6, & GHM8 Wiring Diagram 8-12. Wiring Diagram GHM8 FULL SERVE 380/50/3 WIRING DIAGRAM P/N: 37111-C 70 Wiring Diagram Model: GHM4, GHM6, & GHM8 8-12. Parts List for Wiring Diagram GHM8 FULL SERVE 380/50/3 Item 01 02 03 04 05 06 07 08 09 10 11 12 Part No. 20181 20182 23701 23702 22300 25352 25355 20088 25300 21950 20183 20184 Qty. 10 2 4 4 4 7 14 14 4 2 2 1 Description BLOCK,TERMINAL,24-10GA,30 AMP BLOCK UNIVERSAL GROUND TERMINAL 20-10GA THERMOSTAT, 60-250 DEG, 208-240V, GHM RHEOSTAT, LAMP, 120V, GHM8 LIGHT, PILOT, 250V, ROUND, RED ELEMENT, ROUND, 719/957W, 208/240V, GHM BASE,GHM,LAMP,CERAMIC LAMP,150W/250V,TEFLON COATED WIRENUT, 73B IDEAL ORANGE HOLDER, FUSE, 300V, 15A, SC 0 TO 15 MARKING STRIP,TERM.BLKS,PHOENIX,UK5N_ BRIDGE, UNIVERSAL TERMINAL BLOCK, UK5N 71 Model: GHM4, GHM6, & GHM8 Notes: 72 Wiring Diagram Giles Enterprises, Inc. P.O. Box 210247 • 2750 Gunter Park Drive West • Montgomery, Al 36121-0247 USA (334) 272-1457 • Service Hotline 1-800-554-4537 (USA & Canada Only) • FAX (334) 272-3561 • www.gilesent.com Form No. 60329 (Release date: 09/00)(Revision Date: 10/01/03)(Rev B)(CSY)