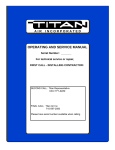

Download Service Manual for Flame Safeguard & Combustion Controls

Transcript