Download USER MANUAL

Transcript

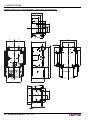

OEM USER MANUAL KPM302 KPM303 Commands manual 77200000030600 CUSTOM ENGINEERING S.p.A. Str. Berettine 2 43010 Fontevivo (PARMA) - Italy Tel. : +39 0521-680111 Fax : +39 0521-610701 http: www.custom.biz Customer Service Department: Email : [email protected] © 2012 CUSTOM ENGINEERING S.p.A. – Italy. All rights reserved. Total or partial reproduction of this manual in whatever form, whether by printed or electronic means, is forbidden. While guaranteeing that the information contained in it has been carefully checked, CUSTOM ENGINEERING S.p.A. and other entities utilized in the realization of this manual bear no responsibility for how the manual is used. Information regarding any errors found in it or suggestions on how it could be improved are appreciated. Since products are subject to continuous check and improvement, CUSTOM ENGINEERING S.p.A. reserves the right to make changes in information contained in this manual without prior notification. The pre-installed multimedia contents are protected from Copyright CUSTOM ENGINEERING S.p.A. Other company and product names mentioned herein may be trademarks of their respective companies. Mention of third-party products is for informational purposes only and constitutes neither an endorsement nor a recommendation. CUSTOM ENGINEERING S.p.A. assumes no responsibility with regard to the performance or use of these products. THE IMAGES USED IN THIS MAN- GENERAL SAFETY INFORMATION Your attention is drawn to the following actions that could compromise the characteristics of the product: • Read and retain the instructions which follow. • Follow all indications and instructions given on the device. • Make sure that the surface on which the device rests is stable. If it is not, the device could fall, seriously damaging it. • Make sure that the device rests on a hard (non-padded) surface and that there is sufficient ventilation. • When positioning the device, make sure cables do not get damaged. • Use the type of electrical power supply indicated on the device label. If uncertain, contact your dealer. • Make sure the electrical system that supplies power to the device is equipped with a ground wire and is protected by a differential switch. • Do not block the ventilation openings. • Do not insert objects inside the device as this could cause short-circuiting or damage components that could jeopardize printer functioning. • Do not carry out repairs on the device yourself, except for the normal maintenance operations given in the user manual. • Make sure that there is an easily-accessible outlet with a capacity of no less than 15A in the vicinity of where the device is to be installed. • Periodically perform scheduled maintenance on the device to avoid dirt build-up that could compromise the correct, safe operation of the unit. • Before any type of work is done on the machine, disconnect the power supply. • Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. UAL ARE USED AS AN ILLUSTRATIVE EXAMPLES. THEY COULDN’T REPRODUCE THE DESCRIBED MODEL FAITHFULLY. UNLESS OTHERWISE SPECIFIED, THE INFORMATION GIVEN IN THIS MANUAL ARE REFERRED TO ALL MODELS IN PRODUCTION AT THE ISSUE DATE OF THIS DOCUMENT. GENERAL INSTRUCTIONS CUSTOM ENGINEERING S.p.A. declines all responsibility for accidents or damage to persons or property occurring as a result of tampering, structural or functional modifications, unsuitable or incorrect installations, environments not in keeping with the equipment’s protection degree or with the required temperature and humidity conditions, failure to carry out maintenance and periodical inspections and poor repair work. THE CE MARK AFFIXED TO THE PRODUCT CERTIFY THAT THE PRODUCT SATISFIES THE BASIC SAFETY REQUIREMENTS. The device is in conformity with the essential Electromagnetic Compatibility and Electric Safety requirements laid down in Directives 2006/95/CE and 2004/108/CE inasmuch as it was designed in conformity with the provisions laid down in the following Standards: • EN 55022 Class B (Limits and methods of measurements of radio disturbance characteristics of Information Technology Equipment) • EN 55024 (Information Technology Equipment – Immunity characteristics – Limits and methods of measurement) • EN 60950-1 (Safety of information equipment including electrical business equipment) GUIDELINES FOR THE DISPOSAL OF THE PRODUCT The crossed-out rubbish bin logo means that used electrical and electronic products shall NOT be mixed with unsorted municipal waste. For more detailed information about recycling of this product, refer to the instructions of your country for the disposal of these products. • Do not dispose of this equipment as miscellaneous solid municipal waste, but arrange to have it collected separately. • The re-use or correct recycling of the electronic and electrical equipment (EEE) is important in order to protect the environment and the wellbeing of humans. • In accordance with European Directive WEEE 2002/96/EC, special collection points are available to which to deliver waste electrical and electronic equipment and the equipment can also be handed over to a distributor at the moment of purchasing a new equivalent type. • The public administration and producers of electrical and electronic equipment are involved in facilitating the processes of the re-use and recovery of waste electrical and electronic equipment through the organisation of collection activities and the use of appropriate planning arrangements. • Unauthorised disposal of waste electrical and electronic equipment is punishable by law with the appropriate penalties. The format used for this manual improves use of natural resources reducing the quantity of necessary paper to print this copy. POWER SUPPLY INFORMATION The device is fed by a SELV power supply (Safety Extra Low Voltage). When power supply unit is installed as accessory in the end-product, the following items must be considered: • The power supply must be properly bonded to the main protective earthing termination. • A suitable mechanical, electrical and fire enclosure must be provided. • The power supply has been evaluated for use in a pollution degree 2 environment, overvoltage category II. • An appropriate disconnect device must be provided. • The power supply must be installed in compliance with the mounting, creepage, clearance, markings and segregation requirements of the end-use application. CAUTION: PRESENCE OF A LITHIUM BATTERY Risk of explosion if battery is replaced with an incorrect type. Dispose of used batteries according to the instructions. WARNING: PRESENCE OF DANGEROUS VOLTAGES (POWER SUPPLY) Risk of electric shock (accessory power supply). WARNING: PRESENCE OF HAZARDOUS MOVING PARTS INDEX INDEX 1 INTRODUCTION .................................................................................................................................................... 7 1.1 Document structure ...................................................................................................................................... 7 1.2 Explanatory notes used in this manual ........................................................................................................ 7 2 DESCRIPTION ....................................................................................................................................................... 9 2.1 Unpacking the device ................................................................................................................................... 9 2.2 Device components: external views ........................................................................................................... 11 2.3 Device components: side views ................................................................................................................. 17 2.4 Device components: internal views ............................................................................................................ 18 2.5 Keys functions: power up ........................................................................................................................... 19 2.6 Keys functions: stand by ............................................................................................................................ 20 2.7 Status led flashes ....................................................................................................................................... 21 2.8 Triple feeder led flashes ............................................................................................................................. 22 3 INSTALLATION.................................................................................................................................................... 23 3.1 Fixing brackets ........................................................................................................................................... 23 3.2 “BURSTER” configuration .......................................................................................................................... 27 3.3 “CUT AND DROP” configuration ................................................................................................................ 30 3.4 Connections ............................................................................................................................................... 34 3.5 Pinout ......................................................................................................................................................... 35 3.6 Driver.......................................................................................................................................................... 38 4 OPERATION ........................................................................................................................................................ 39 4.1 Adjusting paper width ................................................................................................................................. 39 4.2 Adjusting notch sensors position................................................................................................................ 40 4.3 Turning on the device ................................................................................................................................. 43 4.4 Paper insertion ........................................................................................................................................... 44 5 CONFIGURATION ............................................................................................................................................... 49 5.1 Configuration mode .................................................................................................................................... 49 5.2 Setup report ............................................................................................................................................... 51 5.3 Printer status .............................................................................................................................................. 52 5.4 Printer parameters ..................................................................................................................................... 53 5.5 Ethernet parameters .................................................................................................................................. 57 5.6 Hexadecimal dump .................................................................................................................................... 58 5.7 Calendar clock ........................................................................................................................................... 59 6 MAINTENANCE ................................................................................................................................................... 61 6.1 Printer paper jam........................................................................................................................................ 61 6.2 Triple feeder paper jam .............................................................................................................................. 64 6.3 Planning of cleaning operations ................................................................................................................. 65 6.4 Cleaning ..................................................................................................................................................... 66 6.5 Upgrade firmware....................................................................................................................................... 74 7 SPECIFICATIONS................................................................................................................................................ 76 7.1 Hardware specifications ............................................................................................................................. 76 7.2 Character specifications in ESC/POS™ emulation .................................................................................... 79 7.3 Specifications for RFID reader/writer ......................................................................................................... 80 7.4 Specification for reader of one-dimensional barcode ................................................................................. 80 7.5 Printer dimensions ..................................................................................................................................... 81 7.6 Power supply dimensions cod.963GE020000004 (optional) .................................................................... 90 7.7 Specifications for ticket with barcode ........................................................................................................ 91 7.8 Specifications for ticket with black mark..................................................................................................... 92 7.9 Specifications for ticket with labels............................................................................................................. 93 7.10 Specifications for ticket with hole ............................................................................................................... 93 User manual KPM302-KPM303 5 INDEX 7.11 Specifications for ticket with RFID Tag ....................................................................................................... 95 7.12 Character sets in ESC/POS™ emulation ................................................................................................... 98 7.13 Character sets in SVELTA emulation ....................................................................................................... 105 8 CONSUMABLES ............................................................................................................................................... 107 9 ACCESSORIES ................................................................................................................................................. 109 9.1 Paper roll holder ........................................................................................................................................111 9.2 Adapter cable for power supply................................................................................................................ 115 9.3 Wirings kit with near paper end sensors (for models with triple feeder)................................................... 115 10 ALIGNMENT ...................................................................................................................................................... 117 10.1 Enable alignment ..................................................................................................................................... 118 10.2 Calibration ................................................................................................................................................ 121 10.3 Alignment parameters .............................................................................................................................. 123 10.4 Printing area ............................................................................................................................................. 127 11 TECHNICAL SERVICE ...................................................................................................................................... 129 12 ADVANCED FUNCTIONS ................................................................................................................................. 131 12.1 File sharing............................................................................................................................................... 131 12.2 Embedded Web Server ............................................................................................................................ 132 12.3 Embedded Web Server: access ............................................................................................................... 133 12.4 Embedded Web Server: functions ........................................................................................................... 135 12.5 Locator ..................................................................................................................................................... 137 12.6 Drivers installation .................................................................................................................................... 138 12.7 Logos management ................................................................................................................................. 139 12.8 Fonts management .................................................................................................................................. 141 12.9 Setup ........................................................................................................................................................ 143 6 KPM302-KPM303 User manual 1. INTRODUCTION 1 INTRODUCTION 1.1 Document structure This document includes the following chapters: 1 2 3 4 5 6 7 8 9 10 11 12 INTRODUCTION DESCRIPTION INSTALLATION OPERATION CONFIGURATION MAINTENANCE SPECIFICATION CONSUMABLES ACCESSORIES ALIGNMENT TECHNICAL SERVICE ADVANCED FUNCTIONS information about this document general description of device information required for a correct installation of the device information required to make the device operative description of the configuration parameters of the device information for a correct periodic maintenance technical specification for the device and its accessories description and installation of the available consumables for the device description and installation of the available accessories for the device information required for managing the paper alignment information required for contacting the technical service information about special functions available with the device 1.2 Explanatory notes used in this manual NOTE: Gives important information or suggestions relative to the use of the printer. ATTENTION: Gives information that must be carefully followed to guard against damaging the printer. DANGER: Gives information that must be carefully followed to guard against operator injury or damage. User manual KPM302-KPM303 7 1. INTRODUCTION 8 KPM302-KPM303 User manual 2. DESCRIPTION 2 DESCRIPTION 2.1 Unpacking the device Remove the printer from its carton being careful not to damage the packing material so that it may be re-used if the printer is to be transported in the future. Make sure that all the components illustrated below are present and that there are no signs of damage. If there are, contact Customer Service. KPM302, KPM303 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 1 2 3 4 5 6 1 11. 12. Installation instructions sheet Upper packing frame Power supply cable Spacer (only for standard model) Additional fixing brackets Ruler “CUT AND DROP” configuration kit (only for standard model) Printer Lower packing frame “BURSTER” configuration kit (only for standard model) Lower tray Box 2 3 A FIS LLIN SO EA A RE PA LIGN AL PE GU R G TO T IDA UID HE CA E FIX RT ED A 4 5 6 7 8 W MO ARN VIN ING GP ! AR TS 7 8 9 10 11 12 User manual KPM302-KPM303 9 2. DESCRIPTION KPM302 (models with triple feeder) 1 A FIS LLIN SO EA A RE PA LIGN AL PE GU R G TO T IDA UID HE CA E FIX RTA ED 3 4 5 6 7 8 3 2 2 1 1. Installation instructions sheet 2. Ruler 3. “CUT AND DROP” configuration kit (only for standard model) 4. “BURSTER” configuration kit (only for standard model) 5. Power supply cable 6. Printer 7. Lower packing frame 8. Box W MO ARN VIN ING GP ! AR TS 4 5 6 7 8 • • • • Open the printer packaging Remove the upper packing frame content and remove the upper packing frame. Take out the printer. Keep the box, trays and packing materials in the event the printer must be transported/shipped in the future. 10 KPM302-KPM303 User manual 2. DESCRIPTION 2.2 Device components: external views KPM302, KPM303 (standard models) 1. Printing head group 7. Status led 2. Release lever 8. Paper input 3. LINE FEED key 9. Cutter cover 4. FORM FEED key 10. Paper outfeed 5. S1 key 11. External near paper end sensor connector 6. S2 key 12. Printer chassis 1 2 3 4 5 6 7 8 12 11 10 9 User manual KPM302-KPM303 11 2. DESCRIPTION KPM302, KPM303 (models with ejector) 1. Printing head group 7. Status led 2. Release lever 8. Paper input 3. LINE FEED key 9. Cutter cover with ejector group 4. FORM FEED key 10. Paper outfeed 5. S1 key 11. External near paper end sensor connector 6. S2 key 12. Printer chassis 1 2 3 4 12 11 10 9 12 KPM302-KPM303 User manual 5 6 7 8 2. DESCRIPTION KPM302, KPM303 (models with selector) 1. Printing head group 8. Paper input 2. Release lever 9. Cutter cover with selector group 3. LINE FEED key 10. Tilting slide 4. FORM FEED key 11. Sensor for tilting slide position 5. S1 key 12. Paper outfeed 6. S2 key 13. External near paper end sensor connector 7. Status led 14. Printer chassis 1 2 3 4 5 6 7 8 14 13 12 11 10 9 User manual KPM302-KPM303 13 2. DESCRIPTION KPM302 (standard models with triple feeder) 1. Printer chassis 9. Triple feeder 2. Printing head group 10. Paper input feeder 1 3. Release lever 11. Paper input feeder 2 4. LINE FEED key 12. Paper input feeder 3 5. FORM FEED key 13. Triple feeder led (green) 6. S1 key 14. Triple feeder led (red) 7. S2 key 15. Paper outfeed 8. Status led 16. Cutter cover 1 16 15 14 KPM302-KPM303 2 3 14 User manual 4 13 5 6 7 8 9 10 11 12 2. DESCRIPTION KPM302 (models with triple feeder and ejector) 1. Printer chassis 9. Triple feeder 2. Printing head group 10. Paper input feeder 1 3. Release lever 11. Paper input feeder 2 4. LINE FEED key 12. Paper input feeder 3 5. FORM FEED key 13. Triple feeder led (green) 6. S1 key 14. Triple feeder led (red) 7. S2 key 15. Paper outfeed 8. Status led 16. Cutter cover with ejector group 1 16 15 2 3 14 4 5 6 7 8 9 10 11 12 13 User manual KPM302-KPM303 15 2. DESCRIPTION KPM302 (models with triple feeder and selector) 1. Printer chassis 10. Paper input feeder 1 2. Printing head group 11. Paper input feeder 2 3. Release lever 12. Paper input feeder 3 4. LINE FEED key 13. Triple feeder led (green) 5. FORM FEED key 14. Triple feeder led (red) 6. S1 key 15. Paper outfeed 7. S2 key 16. Tilting slide 8. Status led 17. Sensor for tilting slide position 9. Triple feeder 18. Cutter cover with selector group 1 18 17 16 15 16 KPM302-KPM303 2 3 14 User manual 4 13 5 6 7 8 9 10 11 12 2. DESCRIPTION 2.3 Device components: side views KPM302, KPM303 1. 2. 3. 4. 5. USB connector RS232 connector ETHERNET connector SD/MMC card Power Supply connector 1 2 3 4 5 3 4 KPM302 (models with triple feeder) 1. 2. 3. 4. 5. 6. Cover for triple feeder connectors USB connector RS232 connector ETHERNET connector SD/MMC card Power Supply connector 1 2 5 User manual 6 KPM302-KPM303 17 2. DESCRIPTION 2.4 Device components: internal views 1. 2. 3. 4. 5. 6. 7. 8. Sensors for paper out presence Opening/closing front cover sensor Cutter position sensor Unlocking button for mobile paper guide Mobile sensors for notch Head temperature sensor Sensor of paper presence Opening/closing printer cover sensor 7 6 5 4 3 2 1 1 18 KPM302-KPM303 User manual 7 5 8 2. DESCRIPTION 2.5 Keys functions: power up The following figures show the functions of printer’s keys according to the operating condition of the device. POWER UP LF FF S1 S2 LF FF Hold down FF S1 S2 LF Hold down print the SETUP report with printer parameters LF S1 LF Fast push FF S1 LF S2 FF S1 S2 Fast push modify selected parameter LF FF S1 S2 Fast push LF FF S1 S2 LF FF S1 S2 Fast push enter the CLOCK SETUP print the SETUP report with Ethernet parameters and enter the SETUP MODE LF S2 initialize the notch sensor and characterizes the paper Fast push enter the SETUP MODE for the printer parameters S1 Hold down perform the FONT TEST S2 FF FF S1 S2 Fast push skip the SETUP MODE LF FF S1 S2 Fast push next parameter exit the SETUP MODE NOTE: During power-up, do not press the S2 key because the printer enter in a test modality that becomes unusable by keys; if this event occurs then turn off the printer and turn on without pressing any key. User manual KPM302-KPM303 19 2. DESCRIPTION 2.6 Keys functions: stand by STANDBY LF FF S1 S2 LF Fast push S1 S2 Fast push advance the paper (manual feed) advance the paper (preset length) * Only with alignment enabled. 20 KPM302-KPM303 FF User manual LF FF S1 S2 Fast push perform the ticket alignment and the cut * 2. DESCRIPTION 2.7 Status led flashes The Status led indicates hardware status of device. Given in the table below are the various led signals and the corresponding printer status. STATUS LED DESCRIPTION - OFF PRINTER OFF GREEN ON PRINTER ON : NO ERROR 1x RECEIVING DATA GREEN 2x RECEIPT ERRORS (PARITY, FRAME ERROR, OVERRUN ERROR) COMMUNICATION STATUS 3x COMMAND NOT RECOGNIZED 4x COMMAND RECEIPT TIME OUT 2x PRINT HEAD OVER TEMPERATURE 3x PAPER END 4x PAPER JAM 5x POWER SUPPLY VOLTAGE INCORRECT 6x COVER OPEN 3x RAM ERROR RED 4x EEPROM ERROR UNRECOVERABLE ERROR 5x CUTTER ERROR 6x CUTTER COVER OPEN YELLOW RECOVERABLE ERROR User manual KPM302-KPM303 21 2. DESCRIPTION 2.8 Triple feeder led flashes KPM302 (models with triple feeder) The led panel of triple feeder is comprised of two led (one of green colour and one of red colour) for each of the three paper input feeder. The led indicate the triple feeder status and the paper status. Given in the table below are the various led signals and the corresponding triple feeder status. STATUS LED DESCRIPTION OFF PAPER PRESENCE ON NEAR PAPER END OFF NO PAPER OR PAPER IN PARKING SPACE (1) ON PAPER LOADED slow PAPER END DURING PRINTING fast PAPER JAM RED PAPER END WARNING GREEN TRIPLE FEEDER STATUS NOTE: (1) : The paper is in “parking space” when it is present on the entrance of feeder but it is not loaded into the printer. 22 KPM302-KPM303 User manual 3. INSTALLATION 3 INSTALLATION 3.1 Fixing brackets KPM302 (models without triple feeder), KPM303 The printer includes a kit for the assembly of two additional fixing brackets (see following figure). The kit contains: 1. Two fixing brackets; 2. No.4 fixing screws. 1 1 2 Assembly instructions Fix the brackets to the printer as shown in the following figures. 1 2 User manual KPM302-KPM303 23 3. INSTALLATION The following figure shows the printer overall dimensions with the two additional brackets (dimensions in mm). 31 150 10 45 150,1 5 - N°4 Slots 110 162,1 55 M4 - N°4 holes 10 127 85 200,24 42,5 4,7 1,5 86,5 123 2,5 191 16,5 50,9 24 KPM302-KPM303 114,3 User manual 129 16,5 3. INSTALLATION The following figure shows the overall dimensions of the printer with the “CUT AND DROP” configuration and the two additional brackets (dimensions in mm). 31 150 10 45 150,1 5 - N°4 Slots 110 162,1 55 M4 - N°4 holes 10 127 85 200,2 42,5 4,7 1,5 90,4 123 10,1 191 16,5 50,9 129 16,5 114,3 User manual KPM302-KPM303 25 3. INSTALLATION The following figure shows the overall dimensions of the printer with the “BURSTER” configuration and the two additional brackets (dimensions in mm). 31 150 10 45 150,1 5 - N°4 Slots 110 162,1 55 M4 - N°4 holes 10 127 200,2 191 4,7 42,5 1,5 86,5 123 2,5 4,5 85 50,9 26 KPM302-KPM303 114,3 User manual 16,5 129 16,5 3. INSTALLATION 3.2 “BURSTER” configuration KPM302 (standard models and models with triple feeder) KPM303 (standard models) Printer is provided with a kit for the “BURSTER” configuration (see the following figure). The kit contains: 1. Upper paper out feed mouth. 1 For the assembly procedure, proceed as follows: 1 Open the printer cover. User manual KPM302-KPM303 27 3. INSTALLATION 2 Unscrew the two fixing screws and take off the upper paper mouth group of the “STANDARD” configuration. Unscrew the central fixing screw and divide the paper mouth from the light guide. 3 Unscrew the fixing pins and take off the fixed blade and the spring. 28 KPM302-KPM303 User manual 3. INSTALLATION 4 Fix the light guide with the upper paper mouth of the “BURSTER” configuration using the screw previously removed. 5 Fix the upper paper mouth group for the “BURSTER” configuration using the screws previously removed. User manual KPM302-KPM303 29 3. INSTALLATION 3.3 “CUT AND DROP” configuration KPM302 (standard models and models with triple feeder) KPM303 (standard models) Printer is provided with a kit for the “CUT AND DROP” configuration (see following figure). The kit contains: 1. Label. 2. Upper paper out feed mouth. W MO ARN VIN ING GP ! AR 1 TS For the assembly procedure, proceed as follows: 1 Open the printer cover. 30 KPM302-KPM303 User manual 2 3. INSTALLATION 2 Unscrew the two fixing screws and take off the upper paper mouth group of the “STANDARD” configuration. 3 Using a clamp, remove the precut sheet metal on the printer cover. User manual KPM302-KPM303 31 3. INSTALLATION 4 Fix the upper paper mouth group for the “STANDARD” configuration in the upper holes on the printer cover using the screws previously removed. 5 Unscrew the two fixing screws on the cutter cover and take off the lower paper mouth of the “STANDARD” configuration. 32 KPM302-KPM303 User manual 3. INSTALLATION 6 Fix the lower paper mouth for the “CUT AND DROP” configuration by using the screws previously removed. 7 W MO ARN VIN ING GP ! AR TS W MO ARN VIN ING GP ! AR TS Close the printer cover and paste the label (supplied with the kit) on the cutter cover. User manual KPM302-KPM303 33 3. INSTALLATION 3.4 Connections RS232 PC Power Supply cable (supplied) ETHERNET CrossOver standard cable Serial standard cable USB standard cable USB ETHERNET UTP standard cable (pin-to-pin) The following figures show the possible connections for device. HUB POWER SUPPLY WARNING: In some using conditions, we recommend the installation of a ferrite core on the power supply cable. 34 KPM302-KPM303 User manual 3. INSTALLATION 3.5 Pinout 6 4 3 1 POWER SUPPLY Male Molex connector vertical (no. 39-30-0060) 1 +24 Vdc 2 +24 Vdc 3 +24 Vdc J26 4 GND 5 GND 6 GND ATTENTION: Respect power supply polarity. Note: Power supply cable The following figure shows the connector pinout of the power supply cable for the device: Female connector Molex (n.39-01-2065) 4 1 Power supply cable 2 6 3 PIN Cable color Signal 1 Red +24V 2 not connected +24V 3 Red +24V 4 Black GND 5 not connected GND 6 Black GND 1 USB INTERFACE Female USB type B connector 3 4 1 USB-VBUS J13 (out) 2 PD -0 3 PD +0 4 GND User manual KPM302-KPM303 35 3. INSTALLATION 5 9 1 6 RS232 SERIAL INTERFACE Female DB9 connector 1 DTR 2 TX During transmission, takes the values “0” and “1” depending on data. 3 RX During reception, takes the values “0” and “1” depending on data. 4 n.c. J1 5 GND 6 DTR When “1”, printer is power on. 7 CTS 8 RTS When “1”, printer is ready to receive data 9 n.c. Note: Given the presence of the RS232 standard, logic value “0” corresponds to a voltage level of between +3Vdc and +15Vdc and logic value “1” corresponds to a voltage level of between -3Vdc and -15Vdc. 1 2 3 4 5 6 7 8 9 DEVICE DCD RXD TXD SIGNAL GND DSR CTS 1 2 3 4 5 6 7 8 9 DB9 DB9 Note: KPM302-KPM303 > PC connection The following pictures shows an example of connections between the printer and a personal computer using a 9 pin female RS232 serial connectors: PC Note: When use a serial cable, we recommend the installation of a ferrite core on the power supply cable. 36 KPM302-KPM303 User manual 3. INSTALLATION ETHERNET INTERFACE 1 8 Female RJ45 connector 1 TPOUT + 2 TPOUT 3 TPIN + 4 GND 5 GND 6 TPIN J16 7 n.c 8 n.c 9 +3.3 V 10 LED-LAN 11 +3.3 V 12 LED-LNK 13 Shield 14 Shield Note: The functionality of two led are specified in the following table: LED FUNCTION LED-LNK Link (yellow color): the led lights up when a connection is active LED-LAN Rx/Tx: (green color): the led lights up when occurs a data reception or transmission • To directly connect the printer to a Personal Computer, use a Cross-Over Ethernet cable. • To connect the printer to a hub device, use an UTP Ethernet cable (Pin to Pin). Note: The pinout shown in table represents the input signals to component J15 before the isolation voltage transformer (through-hole pin). User manual KPM302-KPM303 37 3. INSTALLATION 3.6 Driver The drivers are available for the following operating system: OPERATING SYSTEM DRIVER INSTALLATION PROCEDURE Windows XP Windows VISTA (32/64bit) Windows Windows 7 (32/64bit) From the START menu, press Enter and key-in the path where the SW was saved on your PC, then click OK. Follow the instructions that appear on the screen to install the driver. OPOS (only for KPM302) Follow the instruction get back on the README.TXT file you can find it in the software package downloaded in advance. Linux Windows / Linux JavaPOS (only for KPM302) Extract the zipped folder to the destination path desired. All drivers can be found in the DOWNLOAD section of the web site www.custom.biz. 38 KPM302-KPM303 User manual 4. OPERATION 4 OPERATION 4.1 Adjusting paper width KPM302 (models without triple feeder), KPM303 Paper width may be adjusted from 40mm to 82,5mm by pressing the unlocking button and moving the mobile paper guide as shown in the following figure. To manage paper width from 40mm to 20 mm, apply the spacer on the mobile paper guide (see following figure), then adjust the paper width. User manual KPM302-KPM303 39 4. OPERATION 4.2 Adjusting notch sensors position Printer is provided with two mobile sensors for the notch detection both on the non-heat sensitive side (lower sensor) and on the heat-sensitive side of paper (upper sensor) as shown in the following figure. The “Notch/B.Mark Position” parameter of printer configuration (see par.5.4) sets the position for the notch as follows: • • Notch positioned on the non-heat sensitive side : Notch positioned on the heat-sensitive side : “Notch/B.Mark Position” = “Bottom” “Notch/B.Mark Position” = “Top” NON-HEAT SENSITIVE SIDE HEAT SENSITIVE SIDE n io ct d re di of fee r pe pa n io ct d re di of fee r pe pa LOWER MOBILE SENSOR FOR NOTCH UPPER MOBILE SENSOR FOR NOTCH 40 KPM302-KPM303 User manual 4. OPERATION To adjust the mobile sensor position according to the notch position on paper, proceed as follows: 1 Blade Lift the release lever. 2 ATTENTION: Pay attention to not work near the cutter blade with the finger (see the figure), because the cutter blade exposes its sharp part. 3 Open the printer cover. for models without triple feeder Adjust the paper width as described in par.4.1. User manual KPM302-KPM303 41 4. OPERATION 7 4 8 ALIGN TO THE FIXED XED ED D PAPER GUIDE ALLINEARE AL GUIDA CARTA CA ARTA AR RTA FISSO 1 2 3 4 5 6 7 8 Place the ruled supplied against the fixed paper guide on the lower flat. Move the lower sensor to the desired position using a small screwdriver or a pointed object. 6 ALIGN TO THE FIXED PAPER GUIDE 6 5 4 3 2 1 ALLINEARE AL GUIDA CARTA FISSO 7 8 1 2 5 ATTENTION: To avoid damaging the sensors, use the plastic tabs as foothold for the screwdriver to push the sensor in the desired position. Close the printer cover. Place the ruled supplied against the appropriate fin on the upper flat. Move the upper sensor to the desired position using a small screwdriver or a pointed object. 42 KPM302-KPM303 User manual 4. OPERATION 4.3 Turning on the device 3 1 EXTERNAL POWER SUPPLY UNIT (OPTIONAL) Power Supply cable (supplied) Connect the power supply cable (supplied) to an external power supply unit (optional). The green led turns on and the printer is ready. 2 Power Supply cable (supplied) Connect the power supply cable to the connector of the printer (see par.3.4). User manual KPM302-KPM303 43 4. OPERATION 4.4 Paper insertion Each time you change the paper, check inside the printer. To change the paper proceed as follows: KPM302 (models without triple feeder), KPM303 1 Blade Lift the release lever. 2 ATTENTION: For models with cutter, pay attention to not work near the cutter blade with the finger (see the figure), because the cutter blade exposes its sharp part. 3 Open the printer cover. 44 KPM302-KPM303 User manual Adjust the paper width as described in par.4.1. 4. OPERATION 6 7 4 8 XED ED D ALIGN TO THE FIXED PAPER GUIDE ALLINEARE AL GUIDA CARTA CA ARTA AR RTA FISSO 1 2 3 4 5 6 7 8 ATTENTION: Make sure the cut is straight. Adjust the notch sensors position as described in par.4.2. 5 Insert the paper edge into the feed slot (place the paper roll so that it unrolls correctly). 7 VROOM Close the printer cover. Wait for the paper to load automatically. User manual KPM302-KPM303 45 4. OPERATION KPM302 (models with triple feeder), KPM303 1 Blade Lift the release lever. 2 ATTENTION: Pay attention to not work near the cutter blade with the finger (see the figure), because the cutter blade exposes its sharp part. 3 7 8 XED ED D ALIGN TO THE FIXED PAPER GUIDE ALLINEARE AL GUIDA CARTA CA ARTA AR RTA FISSO 3 4 5 6 7 8 User manual 2 46 KPM302-KPM303 1 Open the printer cover. Adjust the position of the notch sensors as described in par.4.2. 4. OPERATION 4 6 UT NP RI R1 DE E FE ER D EE 2 F R3 UT DE NP E I R FE PE UT PA NP I R PE PA E P PA Close the printer cover. 5 ATTENTION: In case of ticket with TAG RFID, load the ticket only into the central feeder (paper input feeder 2). Insert the end of the paper roll in the paper load opening on the triple feeder unit. 7 VROOM ATTENTION: Make sure the cut is straight. Place the paper roll, so that it unrolls correctly. Wait for the paper to load automatically. User manual KPM302-KPM303 47 4. OPERATION 48 KPM302-KPM303 User manual 5. CONFIGURATION 5 CONFIGURATION 5.1 Configuration mode To enter the configuration mode and print a SETUP report with the operating parameters of the printer, proceed as follows. 1 LF FF LINE FEED KEY S1 S2 + POWER SUPPLY During power-up, hold down the LINE FEED key while the wiring is plugged into the power supply connector of the printer. 2 KPM302 printer SCODE: <code> BCODE: <code> FCODE: <code> UCODE: <code> DCODE: <code> CPLD - rel rel rel rel rel rel 1.00 1.00 1.00 1.00 1.00 1.00 PRINTER SETTINGS PRINTER TYPE ...................................KPM302 Barcode Reader ...................................Not Present RFID module ........................................Not Present nt PRINTING HEAD TYPE .................. .... ......KPA KPA PA8 80 80 INTERFACE ........... ......... ....... .............. ...........RS RS S232 2 ETHE HERNET RNET T TYP TYPE YPE....... E ... .... ........ .... ........ .... ........ ...10B .10Base1 ase-T T PRO PROG OGRA RAM M MEMO MEMORY EM RY Y TEST TEST.................O OK DYNA AMIC RAM TE TEST................. ........ ..........OK OK EEPR PROM OM TEST TEST. ST..... ...................................O ........OK ....OKK The device prints a SETUP report. User manual KPM302-KPM303 49 5. CONFIGURATION 3 LF FF S1 S2 LINE FEED KEY LF FF S1 S2 FORM FEED KEY DHCP Client ...................... : Disabled FTP Server ........................ : Enabled IP Address ......................... : 192. 2.168 168 68. 10. 0. 37 37 Subnet Mask k ... ....... ...... ...... ...... ..... ..... : 255 55 255 55.2 55. 255.24 240. 240 0. 0 Def Def efaul aul ultt Gate atewa wayy ... ..... ...... ......... .... : 192 192.1 168. 1. 1. 23 23 Press the LINE FEED key to enter the configuration mode or press the FORM FEED key to print the SETUP report with the Ethernet parameters. 4 [LF] to modify parameter [[FF]] for next p parameter [S2] exit Setup Printer Emulation .......... : ESC/POS (TM) Proceed with the configuration by using the keys according the functions printed on paper. For description and values of setup parameters, see the following paragraphs. NOTE: During power-up, if the LINE FEED key is held down, the printer enters the auto-test routine and prints out the setup report. The printer will remain in standby in Hexadecimal dump mode (see following paragraphs) until another key is pressed or characters are received through the printer communication port. When the FORM FEED key is pressed, the printer enters parameter configuration. When the LINE FEED key is pressed, the printer exits setup and terminates the Hexadecimal dump function. 50 KPM302-KPM303 User manual 5. CONFIGURATION 5.2 Setup report The following figures show the setup reports of the printer. The shown values for parameters are sample values; for the list and the description of printer and Ethernet parameters see the following paragraphs. KPM302 printer PRINTER NAME and FIRMWARE RELEASE SCODE: <code> BCODE: <code> FCODE: <code> UCODE: <code> DCODE: <code> CPLD - rel rel rel rel rel rel 1.00 1.00 1.00 1.00 1.00 1.00 PRINTER SETTINGS PRINTER STATUS (see paragraph 5.3) PRINTER PARAMETERS (see paragraph 5.4) KEYS FUNCTIONS (see paragraphs 2.5 and 2.6) PRINTER TYPE ...................................KPM302 Barcode Reader ...................................Not Present RFID module ........................................Not Present PRINTING HEAD TYPE .......................KPA80 INTERFACE .........................................RS232 ETHERNET TYPE................................10Base-T PROGRAM MEMORY TEST................OK DYNAMIC RAM TEST..........................OK EEPROM TEST....................................OK CUTTER TEST.....................................OK PRINTER HEAD Rav ...........................561 HEAD VOLTAGE [V] = 24.55 HEAD TEMPERATURE [°C] = 26 POWER ON COUNTER = 3 PAPER PRINTED [cm] = 10 CUT COUNTER = 35 Printer Emulation ............................ : RS232 Baud Rate .......................... : RS232 Data Length ........................ : RS232 Parity .................................. : RS232 Handshaking ...................... : Busy Condition ............................... : USB Mass Storage ......................... : USB Address Number .................... : Print Mode ...................................... : Autofeed ......................................... : Chars / inch .................................... : Speed / Quality............................... : Peper Width.................................... : Paper Threshold ............................. : Notch/B.Mark Position .................... : Notch/B.Mark Threshold................. : Notch Distance [mm] ...................... : Ticket Locking................................. : PaperEnd Buffer Clear ................... : Ticket Management ........................ : Paper End Management ................ : RFID Module Baud Rate ................ : Print Density................................... : [LF] [FF] [S1] [S2] ESC/POS (TM) 115200 bps 8 bits/chr None Xon/Xoff RxFull Enabled 0 Normal CR disabled A=15 B=20cpi Normal 82 mm 60% Bottom 40% +00.0 Disabled Disabled Disabled Print All 38400 0% enter Printer Setup enter Ethernet Setup enter Clock Setup skip Setup User manual KPM302-KPM303 51 5. CONFIGURATION KEYS FUNCTIONS (see paragraphs 2.5 and 2.6) [LF] [FF] [S1] [S2] enter Printer Setup enter Ethernet Setup enter Clock Setup skip Setup DHCP Client ................................. : Disabled FTP Server ................................... : Disabled ETHERNET PARAMETERS (see paragraph 5.5) IP Address .................................... : 192.168. 0. 1 Subnet Mask ................................ : 255.255.240. 0 Default Gateway........................... : 192.168. 0. 5 MAC Address ............................... : 00-0E-E2-02-0B-0D For advanced printer setup please connect to the site http://192.168.0.1 5.3 Printer status Printer operating status is indicated in the configuration print-out in which, next to the name of the components displayed, the following information is given: PRINTER TYPE is given the device model. Barcode Reader is given the presence of the barcode reader. RFID module is given the presence of the RFID reader/writer. PRINTING HEAD TYPE is given the printing head model. INTERFACE is given the interface present. ETHERNET TYPE is given the connection type for the Ethernet interface. PROGRAM MEMORY TEST the message OK appears if functioning and NOT OK if faulty. DYNAMIC RAM TEST the message OK appears if functioning and NOT OK if faulty. EEPROM TEST the message OK appears if functioning and NOT OK if faulty. CUTTER TEST the message OK appears if functioning and NOT OK if faulty. PRINTER HEAD Rav is given the resistance of a dot head. HEAD VOLTAGE is given the voltage of the head. HEAD TEMPERATURE is given the temperature of the head. POWER ON COUNTER is given the number of power-ups made. PAPER PRINTED is given the number of centimeters of paper printed. CUT COUNTER is given the number of cuts made. 52 KPM302-KPM303 User manual 5. CONFIGURATION 5.4 Printer parameters This printer allows the configuration of the parameters listed in the following table. The parameters marked with the symbol D are the default values. Settings remain active even after the printer has been turned off and they are stored in non-volatile memory. PRINTER EMULATION Available emulations for the device: SVELTA D ESC/POS™ RS232 BAUD RATE Communication speed of the serial interface: 115200 D 57600 38400 19200 9600 4800 2400 1200 NOTE: Parameter valid only with serial interface. RS232 DATA LENGTH Number of bit used for characters encoding: 7 bits/car 8 bits/car D NOTE: Parameter valid only with serial interface. RS232 PARITY Bit for the parity control of the serial interface: None D = parity bit omitted Even = even value for parity bit Odd = odd value for parity bit NOTE: Parameter valid only with serial interface. RS232 HANDSHAKING Handshaking: XON/XOFF D = software handshaking Hardware = hardware handshaking (CTS/RTS) NOTE: Parameter valid only with serial interface. BUSY CONDITION Activation mode for Busy signal: OffLine/ RXFull = Busy signal is activated when the printer is both in OffLine status and the buffer is full Busy signal is activated when the buffer is full RXFull D = NOTE: Parameter valid only with serial interface. USB MASS STORAGE Sharing mode from Mass Storage: Disabled D = sharing mode disabled Enabled = sharing mode enabled USB ADDRESS NUMBER Numerical address code for the univocal identification of the USB device (in case of more than a USB device connected with the same PC): 0D 1 2 3 4 5 6 7 8 9 User manual KPM302-KPM303 53 5. CONFIGURATION PRINT MODE Printing mode: Normal D = enables printing in normal writing way Reverse = enables printing rotated 180 degrees AUTOFEED Setting of the Carriage Return character: CR disabled D = Carriage Return disabled CR enabled = Carriage Return enabled NOTE: The parameter is printed only with ESC/POS™ emulation enabled. CHARS / INCH Font selection: KPM302 models A = 11 cpi, B = 15 cpi D A = 15 cpi, B = 20 cpi KPM303 models A = 16 cpi, B = 23 cpi A = 23 cpi, B = 30 cpi NOTE: CPI = Characters Per Inch NOTE: The parameter is printed only with ESC/POS™ emulation enabled. SPEED / QUALITY Setting of printing speed and printing quality: Normal High Quality High Speed D PRINT WIDTH Width of printing area: 20 mm 22 mm 24 mm 26 mm 28 mm 30 mm 32 mm PAPER THRESHOLD 60% D 70% 80% 62 mm 64 mm 66 mm D 68 mm 70 mm 72 mm 74 mm 76 mm 78 mm 80 mm 82 mm 90% Position of the alignment notch and choice of appropriate notch sensor: Disabled D = Top = Bottom = Transparence = NOTCH/B.MARK THRESHOLD 48 mm 50 mm 52 mm 54 mm 56 mm 58 mm 60 mm Threshold value (in percent) for the recognition of the presence of paper by the paper presence sensor: 30% 40% 50% NOTCH/B.MARK POSITION 34 mm 36 mm 38 mm 40 mm 42 mm 44 mm 46 mm the notch alignment is not performed the notch position is detected by the upper sensor (reflection) the notch position is detected by the lower sensor (reflection) the notch position is detected by both the sensors (transparence) Threshold value (in percent) for the recognition of the presence of notch by the notch sensor: 30% 40% D 50% 60% 70% 80% 90% NOTE: If the “Notch/B.Mark Position” parameter is disabled, this parameter is not printed. 54 KPM302-KPM303 User manual 5. CONFIGURATION NOTCH DISTANCE “Notch Distance” is the minimum distance (in mm) between the upper edge of ticket and the notch (see chapter 10). The numeric value of the distance is made up with the following four parameters for the setting of three digits (two for the integer part of the number and one for the decimal part) and of the sign: Sign setting: NOTCH DISTANCE SIGN + D = positive distance -= negative distance Setting the digit for tens: NOTCH DISTANCE [mm x 10] 0D 1 2 3 4 5 6 7 8 9 Setting the digit for units: NOTCH DISTANCE [mm x 1] 0D 1 2 3 4 5 6 7 8 9 Setting the digit for decimals: NOTCH DISTANCE [mm x .1] 0D 1 2 3 4 5 6 7 8 9 NOTE: For example, to set the notch distance to 15 mm, modify the parameters as follows: Notch Distance Sign =+ Notch Distance [mm x 10] = 1 Notch Distance [mm x 1] = 5 Notch Distance [mm x .1] = 0 NOTE: If the “Notch/B.Mark Position” parameter is disabled, the parameters for the “Notch Distance” are not printed. TICKET LOCKING This parameter enables/disables the block of the paper inside the device where the ticket is not cut with the cutter, but is presented for the manual tear off by the user: KPM302, KPM303 Disabled D = paper block disabled Enabled = paper block enabled KPM302 (models with triple feeder) Disabled D = paper block disabled By Printer = the motor remain switched on also at the printing end By Feeder = stops the paper of the not active (idle) feeders in order to avoid that the paper parked in a idle feeder, is dragged inside the printer Complete = ticket locking by printer and feeder (combination of the two previous effects) NOTE: If the “Notch/B.Mark Position” parameter is disabled, the parameter is not printed. PAPEREND BUFFER CLEAR Cleaning mode of the data in receive buffer, if the printing is stopped due to lack of paper: Disabled D = The data remain in the receive buffer. When the paper runs out, the printer keeps the remaining data in the receive buffer and prints the remaining portion of the ticket after that the new paper is loaded. Enabled = When the paper runs out, all data in the receive buffer are deleted. User manual KPM302-KPM303 55 5. CONFIGURATION TICKET MANAGEMENT This parameter allows the ticket management: Disabled D = no check Short Ticket = it is possible to manage tickets with length less than the distance between the notch sensor and the printing line Check First = before printing, the device checks the integrity of the first ticket PAPER END MANAGEMENT (only for models with triple feeder) Management of the paper end sensors of triple feeder: Print All D = when the paper end sensor of a feed line of the triple feeder detects the paper end, it is not possible to change the feed line until all tickets remaining in that feed line are printed (so that the paper sensors of the printer will have detected the end of paper) when the paper end sensor of a feed line of the triple feeder detects the paper end, the printer automatically ejects the paper remaining on that feed line and prints diagonal voiding lines on the remaining tickets when the paper end sensor of a feed line of the triple feeder detects the paper end, the printer performs a paper retracting up to the parking position Eject = Retract = RFID MODULE BAUD RATE Communication speed of the RFID module: 115200 57600 38400 D 19200 9600 4800 2400 1200 NOTA: if the RFID module is not recognized in the printer status (“RFID module = Not Present”), set this parameter on the correct value. PRINT DENSITY Adjusting the printing density: -50% -37% -25% 56 KPM302-KPM303 -12% 0D +12% User manual +25% +37% +50% 5. CONFIGURATION 5.5 Ethernet parameters This printer allows the configuration of the parameters listed in the following table. The parameters marked with the symbol D are the default values. Settings remain active even after the printer has been turned off. DHCP CLIENT Setting of the DHCP protocol: Disabled D = protocol disabled Enabled = protocol enabled FTP SERVER Setting of the FTP server: Disabled D = server disabled Enabled = server enabled IP ADDRESS IP address of printer; this parameter is assigned by the network administrator. NOTE: Press the FORM FEED key to modify the value of the highlighted digit. Pressing LINE FEED key to move the cursor on the next digit (if the cursor is on the latest digit, proceed to next parameter by pressing the LINE FEED key). SUBNET MASK This parameter identifies the local network address. NOTE: Press the FORM FEED key to modify the value of the highlighted digit. Pressing LINE FEED key to move the cursor on the next digit (if the cursor is on the latest digit, proceed to next parameter by pressing the LINE FEED key). DEFAULT GATEWAY This parameter identifies the Gateway IP address used to send applications to the external network. NOTE: Press the FORM FEED key to modify the value of the highlighted digit. Pressing LINE FEED key to move the cursor on the next digit (if the cursor is on the latest digit, proceed to next parameter by pressing the LINE FEED key). MAC ADDRESS This is the number, provided by the constructor, that identifies the printer; this number is univocal. NOTE: This parameter can’t be modified by set up. ATTENTION: Any changes to network parameters will interrupt browser connection. If the server not responding you must reconnect to the new IP address set. User manual KPM302-KPM303 57 5. CONFIGURATION 5.6 Hexadecimal dump This function is used to diagnose the characters received through the communication port; the characters are printed out both as hexadecimal codes and ASCII codes. Once the self-test routine has finished, the printer enters Hexadecimal Dump mode. The printer remains in standby until a key is pressed or characters are received through the communication port. For example, in the 200 dpi model, for every 8 characters received, the hexadecimal and corresponding ASCII codes are printed out (if the characters are underlined, the receive buffer is full). Shown below is an example of a Hexadecimal Dump: 48 65 78 61 64 65 63 69 Hexadeci 6D 61 6C 20 64 75 6D 70 mal dump 20 66 75 6E 63 74 69 6F functio 6E 20 30 31 32 33 34 35 n 012345 36 37 38 39 61 62 63 64 6789abcd 65 66 67 68 69 6A 6B 6C efghijkl 6D 6E 6F 70 71 72 73 74 mnopqrst 75 76 77 78 79 7A 58 KPM302-KPM303 User manual uvwxyz 5. CONFIGURATION 5.7 Calendar clock The printer is equipped with a Real Time Clock. During power-up, held down the LINE FEED key to enter in the printer configuration mode. Pressing the S1 key to enter in the clock configuration (see following figure). Pressing the LINE FEED key to modify date / time; the printer will be print the updated the date and time. Follow the instructions printed on the paper for the key functionality. The highlighted digit (the number is written in negative mode) indicates the digit to be modified. Pressing LINE FEED key to modify the value of the highlighted digit; every single LINE FEED key pressure increases of 1 his value. Once the value 9 is reached the counting starts again from 0. Pressing FORM FEED key to move the cursor on the next digit; if the cursor position is on the latest digit you can proceed to next parameter pressing the FORM FEE key again. Pressing S2 key to exit and terminate the setting procedure. CLOCK SETUP [LF] to modify date/time [FF] to next field [S2] to exit 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 01/01/12 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 12:00:00 Date Time Setting : 01/01/12 12:00:00 User manual KPM302-KPM303 59 5. CONFIGURATION 60 KPM302-KPM303 User manual 6. MAINTENANCE 6 MAINTENANCE 6.1 Printer paper jam In case of paper jam proceed as follows: 1 Blade Lift the release lever. ATTENTION: Pay attention to not work near the cutter blade with the finger (see the figure), because the cutter blade exposes its sharp part. 3 2 Open the printer cover. Open the frontal cover. User manual KPM302-KPM303 61 6. MAINTENANCE 6 4 ATTENTION: Do not let water or other liquids get inside the device. Do not insert any kind of object inside the device. Close the printer cover. 7 Remove the damaged paper and check the presence for paper scraps inside the printer; carefully remove all scraps of paper. If necessary, use tweezers. 5 ATTENTION: Make sure the cut is straight. Close the frontal cover. 62 KPM302-KPM303 User manual Insert the paper edge into the feed slot (place the paper roll so that it unrolls correctly). 6. MAINTENANCE 8 VROOM Wait for the paper to load automatically. User manual KPM302-KPM303 63 6. MAINTENANCE 6.2 Triple feeder paper jam KPM302 (models with triple feeder) In case of paper jam inside the triple feeder, the green led that corresponds to the input paper jammed flashes quickly. In this case, contact the Customer Service. 1 Il led verde corrispondente all’ingresso carta inceppato del gruppo di caricamento lampeggia velocemente. 2 [email protected] Assistenza Tecnica Inviare una e-mail al Servizio di Assistenza Tecnica (vedere il capitolo 11). 64 KPM302-KPM303 User manual 6. MAINTENANCE 6.3 Planning of cleaning operations The regular cleaning of the device keeps the print quality and extends its life. The following table shows the recommended planning for the cleaning operations. EVERY PAPER CHANGE Printing head Use isopropyl alcohol Printing roll Use isopropyl alcohol Use a soft cloth Window for barcode reading (1) EVERY 5 PAPER CHANGES Cutter Paper path Use compressed air Use compressed air or tweezers Sensors Triple feeder (2) Use compressed air Use the dedicated cleaning kit (3) EVERY 6 MONTHS OR AS NEEDED (1) Case Use compressed air or a soft cloth For specific procedures, see the following pages. NOTE: If you use the device in dusty environments, you must reduce the intervals between the cleaning operations. NOTES: (1) For models with barcode reader. (2) For KPM302 models with triple feeder. (3) For cleaning kit, contact Customer Service. User manual KPM302-KPM303 65 6. MAINTENANCE 6.4 Cleaning For periodic cleaning of the printer, see the instructions below. PRINTING HEAD 1 3 ISOPROPYL ALCOHOL Disconnect the power supply cable. 2 ATTENTION: Do not use solvents, or hard brushes. Do not let water or other liquids get inside the machine. ON Clean the printing head by using a non-abrasive cloth moistened with isopropyl. ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer cover to the lock position. 66 KPM302-KPM303 User manual 6. MAINTENANCE CUTTER 3 1 Open the frontal printer cover. Disconnect the power supply cable. 2 4 ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer cover to the lock position. ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. ON Alcohol, cohol, solvent solve Clean the cutter by using compressed air. User manual KPM302-KPM303 67 6. MAINTENANCE WINDOW FOR BARCODE READING 3 (for models with reader for one-dimensional barcode) 1 Disconnect the power supply cable. 2 ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. Alcohol, cohol, solvent solve Clean the window for barcode reading by using a non-abrasive cloth. ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer cover to the lock position. 68 KPM302-KPM303 User manual ON 6. MAINTENANCE PRINTING ROLL 3 1 Disconnect the power supply cable. 2 ISOPROPYL ALCOHOL ATTENTION: Do not use solvents, or hard brushes. Do not let water or other liquids get inside the machine. ON Clean the printing roll by using a non-abrasive cloth moistened with isopropyl. ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer cover to the lock position. User manual KPM302-KPM303 69 6. MAINTENANCE SENSORS 3 1 Open the frontal cover. Disconnect the power supply cable. 4 2 ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer cover to the lock position. 70 KPM302-KPM303 User manual ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. Alcohol, cohol, solvent solve Clean the printer sensors by using compressed air. ON 6. MAINTENANCE PAPER PATH 3 1 Disconnect the power supply cable. 2 ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. Alcohol, cohol, solvent solve ON Clean the area involved in the passage of paper by using compressed air. ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer cover to the lock position. User manual KPM302-KPM303 71 6. MAINTENANCE TRIPLE FEEDER 3 (only for KPM302-TF) 1 Insert the edge with the rounded corners of the ticket of the cleaning kit in each of the three feeders. Disconnect the power supply cable. 2 4 ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. ATTENTION: Do not touch the head heating line with bare hands or metal objects. Do not perform any operation inside the printer immediately after printing because the head and motor tend to become very hot. Open the upper printer covers to the lock position. 72 KPM302-KPM303 User manual Alcohol, cohol, solvent solve ON Push the ticket to make out a few of centimetres on the flat inside the printer and pull the ticket out of the internal floor. 6. MAINTENANCE CASE 1 Disconnect the power supply cable . 2 ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not let water or other liquids get inside the machine. Alcohol, cohol, solvent solve ON To clean the device, use compressed air or a soft cloth. User manual KPM302-KPM303 73 6. MAINTENANCE 6.5