Download Miller GA-5OGL Specifications

Transcript

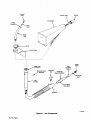

July1988 FORM: Effective With Style No. JA-9 _... MIIIe OWNERS IMPORTANT MODEL GA-5OGL MANUAL Read and understand the entire contents of both this manual and the power source manual used with this unit, with special the safety material throughout both manuals, before in- emphasis on stalling, operating, maintaining this equipment. This unit and these only by persons trained and experienced in the safe operation of welding equipment. Do not allow untrained persons to instructions are install, operate, not or for or use Miller Electric Mfg. Co. AM~G,o~LIa Cornp~n~ ~o. Box 1079 Appleton, WI 54912 USA Tel. 414-734-9821 maintain this unit. Contact your distributor if you do fully understand these instructions. PRINTED IN U.S.A. ADDITIONAL-COPY PRICE 25 CENTS M-1532A .- ~-~-~ -\~-~1-~,mp-~ LIMITED WARRANTY EFFECTIVE: FEBRUARY 18, 1988 supersedes This warranty all previous MILLER warranties and LIMITED WARRANTY - Subject to the terms and is exclusive with or, where authorized in Equipment furnished by Miller is free from defect in workmanship and material as of the time and place of delivery by Miller. No warranty is made by Miller with respect to engines, trade accessories or other items manufactured by others. Such engines, trade accessories and other items are sold subject to the warranties of their respective manufacturers, if any All engines are warranted by their manufacturer for one year from date of original purchase, except Tecumseh engines which . or warranties expressed or implied. the reasonable cost of writing by Miller in appropriate cases, (3) repair or replacement at an authorized Miller service station (4) payment of or or credit for the purchase price (less reasonable depreciation based upon actual use) upon risk and expense. MILLERs return of the goods at Customers option of repair or replacement will be F.O.B., Factory, at Appleton, Wisconsin, or FOB., at a MILLER authorized service facility, therefore, no compensation for transportation costs of any kind will be allowed. Upon receipt of notice of apparent defect or failure, Miller shall instruct the claimant on the warranty claim procedures to be followed. . a two other guarantees In the case of Millers breach of warranty or any other duty with respect to the quality of any goods, the exclusive remedies therefore shall be, at Millers option (1) repair or (2) replacement condi- tions hereof, Miller Electric Mfg. Co., Appleton, Wisconsin warrants to its Distributor/Dealer that all new and unused have no year warranty, ~ as specified below, Millers warranty does not apply components having normal useful life of less than one (1) year, such as spot welder tips, relay and contactor points, MILLERMATIC parts that come in contact with the welding wire including nozzles and nozzle insulators where failure does not result from defect in workmanship or material. to ~/ ~ ~ ~ ~ ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND ANY IMPLIED WARRANTY, GUARANTY OR REPRESENTA T1ON AS TO PERFORMANCE, AND ANY REMEDY FOR BREACH OF CONTRACT WHICH, BUT FOR THIS PROViSION, MIGHT ARISE BY IMPLICATION, OPERATION OF LAW, Miller shall be required to honor warranty claims on warEquipment in the event of failure resulting from a defect within the following periods from the date of delivery of Equipment to the original user: CUSTOM OF TRADE OR COURSE OF DEAUNG, INCLUDING ranted ANY IMPUED WARRANTY OF MERCHANTABIUTY OR OF FITNESS FOR PARTICULAR PURPOSE, WITH RESPECT TO ANY AND ALL EQUIPMENT FURNISHED BY MILLER IS EX j~ 1. Arc welders, p~r sour~, robots, and componente 2. Load banks 3. Original (labor 4. All 6. rr~ 7. N q~J (1 main power rectifiers 1 year only) guns, feeder/guns and torches 5. All other Millermatic Feeders Ł~ ~ ~J - welding Replacement or CLUDED AND DISCLAIMED BY MILLER. 1 year 1 year 3 years EXCEPT ..... repair parts, exclusive of labor Batteries . 1 year 60 days 6 months .. of the date of such failure. As a MILLER CONSUMER USE. MILLERS WARRANTIES DO NOT EXTEND AND NO RESELLER IS AUTHORIZED TO EXTEND MILLERS WARRANTIES TO, ANY CONSUMER. provided that Miller is notified in writing within thirty (30) days TO, matter of submitted AS EXPRESSLY PROVIDED BY MILLER IN ARE INTENDED FOR PRODUCTS ULTIMATE PURCHASE BY COMMERCIAL/INDUSTRIAL USERS AND FOR OPERATION BY PERSONS TRAINED AND IN EXPERIENCED THE USE AND MAINTENANCE OF WELDING EQUIPMENT AND NOT FOR CONSUMERS OR WRITING, 90 days general policy only, Miller may honor claims by the original user within the foregoing periods. . -... ..... ..... April 27, 1990 ERRATA SHEET _____________________ After this manual was to data FORM: OM-1532A printed, refinements appearing later In this manual. In equipment design occurred. This sheet lists exceptions AMENDMENT TO PARTS LIST Amend Parts List as follows: All Parts Eff w/KA27 Part No. Replaced 7-5 7-13 7-17 7-18 7-26 008 931 602 177 Deleted 602 178 856 852 624 134 601 134 600 114 974 7-26 079 079 009 009 625 114973 ** Descnption With Quantit: - **First digit represents page no - SCREW, set sti sch .250-20 x .375 SLEEVE, centering monocoil GUIDE, wire outlet 1/1 6-5/64 LINER, monocoil 1/16-5/64 wire x lift 6in LINER, monocoil i/16-5/64wirex l6ft8in digits following dash represent item no. BE SURE TO PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT PARTS. 1 1 1 1 1 SECTION 1 Rating: 100% Duty Cycle, dcrp 500 Amperes Wire Diameter 1/16 thru 1/8 in. thru 3.2 mm) (1.6 A. Cable Cooling Length Method lOft. 3.0 15 ft. 4.6 Figure 1-1. INTRODUCTION 1-1. Net Air Air m m Ship Weight Weight 12 lbs. 14 lbs. 5.4 kg) 6.4kg) 14 lbs. 6.4 16 lbs. 7.3 kg kg SpecifIcations signal word, IMPORTANT highlights inst ruc special emphasis to obtain the mo~ ef operation of this equipment. A third GENERAL INFORMATION AND SAFETY tions which need General ficient presented in this manual and on various la bels, tags, and plates on the unit pertains to equipment design, installation, operation, maintenance, and troubleshooting which should be read, understood, and followed for the safe and effective use of this equipment. Before installing this equipment, clean all packing ni atenat from around the unit, and carefully inspect for any damage that may have occurred during shipment. Any B. claims for loss Information Safety The and installation, maintenance, operation, troubleshooting of arc welding equipment requires prac tices and procedures which ensure personal safety and the safety of others. Therefore, this equipment is to be installed, operated, and maintained only by qualified persons in accordance with this manual and all applica ble codes such as, but not limited to, those listed at the end of Section 1 Safety Rules For Operation Of Arc Welding Power Source in the welding power source 1-2. RECEIVING-HANDLING or damage that may have occurre d in transit must be filed by the purchaser with the car ler. A copy of the bill of lading will be furnished by the m nu facturer on request if occasion to file claim arises. When requesting information concerning this e~ u ip ment, it is essential that Model Description and tyle Number of the 1-3. equipment be supplied. DESCRIPTION - Owners Manual. Safety instructions specifically pertaining to this unit ap pear throughout this manual highlighted by the signal words WARNING and CAUTION which identify differ ent levels of hazard. WARNING statements include installation, operation, and maintenance procedures or practices which If not carefully followed could result in serious personal injury or loss of life. This gun is designed specifically for use in conjun tion with the self-shielding Flux Cored Arc Welding process. component~ for The gun is shipped with the necessary the specific wire size ordered. Through minor in parts the gun may be used with 1/16, .068/.072, char~iges ~/64, or 3.2 Mm) 3/32, 7/64, or 1/8 in. (1.6, 1.8, 2.0, 2.4, 2.8, flux cored wire. The GA.5OGL is designed for matic scratch start open arc welding. An optional had-held flux hopper extends the cap~ Lbili ties to include manual Submerged Arc Welding. Th ~aI pha-numeric designation refers CAUTION statements include installation, operation, and maintenance procedures or practices which if not carefully damage followed could result in minor personal to this equipment. injury semi~uto to the following: G-gun A air cooled 50 ampere rating: 500 ampere GL gasless or - - - SECTION 2-INSTALLATION a WARNING: ELECTRIC SHOCK can kill. 2-1. GUN/FEEDER CONNECTOR INSTALLA1 ION Do not touch live electrical parts. (FIgure 2-1) Shut down welding power source and discon input power employing lockout/tagging proceduresbe fore installing gun. Proceed as follows to install the gun/feeder into the drive assembly on the wire feeder. Lockout/tagging procedures consist of pad locking line disconnect switch in open position, removing fuses from fuse box, or shutting off and red-tagging circuit breaker or other discon necting device. IMPORTANT: The outlet the gun assembly. nect 1. guide is provided Loosen the gun/feeder connector the wire drive assembly. COflflE as securing ctor p~ rt of kno Ofl OM-1532P gel Contact Nozzle Tube Flux Hopper Thread Stub Liner Head Tube / / Hand Guard / / / / Outlet Head Tube Rear Connector Centering Guide Sleeve Monocoli Uner Setscrew Lubricator Cup Centering Sleeve Setscrew Monocoll Ll~er Gun 4 _______ Handle Connector Insulator TC-044 585 Figure OM-1532 Page 2 2-1. Gun Components IMPORTANT: The outlet guide should be positioned as close as possible to the drive rolls without touching them. This gives the wire maximum column strength 2. thus 3. eliminating waves. Loosen the clamp securing the hand guard, move the hand guard. Install hand-held flux an hopper assembly into ead ~Op tube connector. Insert the 2. gun/feeder connector into the wire drive 2-4. assembly. re INSTALLATION OF TRIGGER SWITCH tional) 3. Tighten the NOZZLE 2-2. gun/feeder connector securing knob. IMPORTANT: The installation of trigger switch ad~pts the GA-5OGL gun for use with any feeder requiring a (Optional) (44.5 mm) nozzle is recommended for normal application. If longer stick out of the electrode is desired, a 2-3/8 in. (60 mm) nozzle is available. The gun is shipped with a thread protector which should be used A 1-3/4 in. when a switch-type starting system. 1. nozzle is not, 2-3. INSTALLATION OF HAND-HELD FLUX HOPPER (Optional) (Figure 2-1) 2. SECTION. 3 The duty cycle of a welding gun period that a gun can output. This gun is rated amphenol gun switch plug into the s~iitch receptacle on the wire feeder. Rotate the plug collar clockwise to lock plug in receptacle. SEQUENCE OF OPERATION at 100 that the gun can be is the percentage of be operated at a can a given operated at rated load con- FUMES AND GASES your health. 3-2. seriously c ha m See Section 1 Safety Rules For Operation Of Arc Welding Power Source in welding power source Owners Manual for basic welding safety information. duty cycle. FLUX CORED AND MANUAL SUBMERGED ARC WELDING ~ can body prot Use enough ventilation to keep fun es and gases from the breathing zone. CAUTION: EXCEEDING DUTY CYCLE RAT ING will damage the welding gun. Do not exceed rated damage hearing. Wear correct eye, ear, and tion. percent duty cycle. This tinuously. 4~ the gun handle and ARC RAYS, SPARKS, AND HOT SUR FACES can burn eyes and skin; NOl E ten minute means trigger switch on supplied clamp. Insert the DUTY CYCLE 3-1. with control Remove the head tube. 1. Position the secure WARNiNG: ELECTRIC SHOCK welding power Ensure that proper eiectncai connections have been made to the welding power source the wire feeder. 2. Ensure that the welding wire has been properly threaded and that correct initial tension has een set on the drive rolls (refer to the wire feeder ~wn an~ can kill, Do not touch IWe electrical parts. Shut down 1. source and wire feeder, and disconnect gun before handling or ers replacing any gun parts. When not in use, store the gun in insulated holder so wire cannot be touched or make con tact with metal surfaces. Wear dry insulated gloves tools when cutting wire. or use 3. Flu hand-held flux 4. Piace control(s) on wire feeder in the desired tion for the welding setup. 5. Place the controls on the welding power source in the desired position for the welding setup (refer to insulated The welding wire and all metal parts in contact with it are electrically hot whenever the wire feeder is connected to an energized welding power supply. Manual). welding 6. power hopper, source if applicable. Owners osi Manual). Energize the welding power source and wire feeder (refer to the respective Owners Manuals). OM-1532 P~ge 3 a ELECTRIC SHOCK can kIll; WARNING: WIRE WELDING can cause puncture wounds. 9. Do not touch live electrical parts. Do not point gun toward any part of the body, any conductive surface, or other personnel when threading welding wire. The welding parts in wire and all metal with it are energized while the source is energized. Touch welding wire to workpiece or press optional Trigger Switch, if applicable, to start wire feed; an arc will be established. If wire slippage is noticed, tighten drive roll pressure adjustment 1/4 turn at a time until slippage stops. Do not overtighten. 10. After the controls on the welding power source and wire feeder are adjusted for normal operation, they will function automatically whenever the welding wire touches the workpiece or the optional Trigger Switch is depressed. Removing welding wire from contact welding power workpiece 7. switch or optional Trigger Switch, if ap plicable, to run the wire out beyond the end of the contact tube. Cut the wire off so it sticks out approxi Actuate mately jog 8. (13 to 19 mm) from the nozzle or hopper nozzle, if applicable. 1/2 to 3/4 in. hand-held flux Hold end of nozzle approximately 1 in. or the releasing Trigger Switch, if appli cable, will break the arc and cause wire feeder to stop. 3-3. SHU111NG DOWN 1. Stop welding (remove 2. Turn off wire from workpiece). (25 mm) from workpi ece. welding power source and wire feeder. SECTION 4- MAINTENANCE a WARNING: ELECTRIC SHOCK ~an kIll. Do not touch live electrical parts. 1. Shut down welding power source and wire feeder and disconnect gun before handling or replacing any gun parts. When not in use, store the gun in insulated holder so wire cannot be touched or make con tact with metal surfaces. Wear dry insulated gloves tools when cutting wire. HOT SURFACES Allow 4-2. or use can cause severe 2. CONTACT TUBE REPLACEMENT Remove nozzle. Cut off any portion of the electrode wire which beyond end of contact tube. 3. Remove contact tube and replace with power 4-1. 4. Replace 4-3. burns. a Lockout/tagging procedures consist of pad locking line disconnect switch in open position, removing fuses from fuse box, or shutting off and red-tagging circuit breaker or other discon necting device. Disconnect gun from feederbe fore Inspect gun for broken area, cracks and loose parts; tighten, repair, and replace as required. 2. any weld spatter or foreign matter which may accumulate around the nozzle orifice. 3. Remove remove any accumulation around the Trigger Switch, if applicable. 5. required all cables; give par ticular attention to frayed and cracked insulation and areas where it enters equipment. or replace kill. frequency 1. Repair can Do not touch live electrical parts. or 4. operation. WARNING: ELECTRIC SHOCK type of maintenance required. Carefully resume Shut down welding power source and discon input power employing lockout/tagging procedures before installing gun. energized welding will determine nozzle and nect supply. shop conditions and contact CHANGING WIRE SIZES (FIgure 2-1) INSPECTION AND UPKEEP Usage and an new tube. The welding wire and all metal parts in contact with it are electrically hot whenever the wire feeder is connected to ex tends insulated cooling period before servicing. (FIgure 2-1) as inspecting servicing. Each time the size of the electrode wire is change the contact tube. changed, it is necessary to IMPORTANT: The contact tube has right-hand threads. When changing to 1/16, .068/.072, or 5/64 in. (1.6, 1.8, or 2.0 mm) wire from any other size, it is necessary to change the monocoil liner, the outlet wire guide, and add sleeve (see parts list). a rear centenng Remove grease and When ture from electrical 1.8, changing from 1/16, .0681.072, or 5/64 in. (1.6, 2.0 mm) wire to any other size, it is necessary to OM-1532 Page 4 grime from components; mois parts and cables. or changethemonocoilliner,theoutletwireguide,andremove the rear centering sleeve. To change the liner and wire guide and add the centering sleeve, proceed as follows: 12. When or remove Remove nozzle 2. Remove head tube or thread protector, or as insi changing to 1/16, .0681.072, or 5/64 in 1 6 th~ 2.0 mm) from any other size wire, ro centering sleeve into the gun/feeder tate the sleeve until the notched portion lines up~ith applicable, or connecto~, optional hand-held flux hop- the lubricator cup hole, and secure the setscrew. per. 3. from 1/16, .068/.072, or 5/64 in. size wire, ren~ove When 1.8, 1. changing (1 .6, 1.8, or 2.0 mm) to any other the rear centering sleeve. Loosen guard clamp securing hand guard, and slide hand on gun handle to gain access to 13. Insert the .068/.07~, monocoil liner. 1/16, or or 2.0 mm) liners must be inserted from the head tube connector end. 5/64 in. back monocoil liner setscrew. new (1.6, 1.8, 14. Reinstall the head lube. 4. Loosen the monocoil liner setscrew. 5. Remove the lubricator cup. IMPORTANT: Ensure that the new monocoil liner butts against the stub liner in the head tube before 6. Remove the outlet wire the 7. Lay the gun out flat secLi!ring guide. new (no coils in cable/conduit). IMPORTANT: 3/32, 7/64, or 1/8 in. (2.4,2.8, or 3.2 mm) liners may be pulled out from either end. 1/16, .0681.072, or5/64 in. (1.6, 1.8, or2.0 mm) liners must be pulled out from the head tube connector end. liner. CAUTION: OVERTIGHTENING LINER SCREW will damage liner. Do not 15. Tighten Remove the monocoil liner. 4~ equipment. Point gun liner only in a safe direction away from personnel and equipment when cleaning with compressed air. gun/feeder 17. Reinstall the connector into the insulator lubricating cup. IMPORTANT: The new monocoil liner is longer than For 3/32 to 1/8 in. (2.4 to 3.2 mm) wire, cut necessary. the liner off 1/4 in. (6.4 mm) beyondthegun/feeder~con nector. 18. lnstailthe 9. Blow out gun casing or liner with compressed air whenever the wire or liner is removed. outlet wire guide. For 1/1 6to 5/64 in. the liner off 1/16 mi (1 .6 cut wire, mm) new to 2.0 (1.6 mm) beyond the wire guide. 10. Slide the 19. 11. Loosen the setscrew. 20. Reconnect power to all eration. gun/feeder connector Out of insulator to gain access to the rear centering sleeve setscrew (see Figure 2-1). liner setscrew (see Figure 2-1). , CAUTION: FLYING DIRT AND METAL PARTICLES can injure personnel and damage - the monocoil liner setscrew. 16. Slide the 8. overtighten ET Reposition hand it to the handle. guard, and tighten clamp equipment and sec~ ring resum OM-1532 op Available Wire Sizes 1.6MM .063 1/16 1.8MM .068/.072 .068/.072 2.4MM .094 3/32 2.0MM .079 5/64 2.8MM .110 7/64 3.2MM .126 1/8 iN), 1 31 29 3 33 9 5 6 10 27 17. ii 21 22 26 Figure OM1532 Page 6 A - Exploded 25 View Of Gun And TC.046 113 Optional Flux Hopper (Gun WIth 1/16 WIre Illustrated) 1 Item No. Figure Part No. Description A Exploded 1 009 709 1 27 090 922 052 055 008926 008 925 008 924 +046 017 +046 018 008 932 +008 931 075 625 075 855 075 626 078981 +008 948 010860 008928 602 177 075628 073357 605789 079856 079852 079851 048827 048826 085210 004733 004 732 004 729 075 644 095949 009 624 088 758 009 625 008 759 078 894 26 052 789 006 868 1 1 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 18 19 19 20 21 22 23 24 25 26 26 26 26 29 30 31 32 33 34 35 36 37 006861 006 870 052 759 006 862 006865 006866 052 808 076183 006863 +046 013 +046 014 085 210 076 123 079 885 079 854 TUBE, TUBE, TUBE, TUBE, TUBE, TUBE, View Of Gun Assembly Qua & Optional Flux tity Hopper contact 1/16 wire 1 contact .068/.072 wire I contact 5/64 wire 1 contact 3/32 wire 1 contact 7/64 wire contact 1/8 wire PROTECTOR, thread TUBE, head 60 deg INSULATOR, handle LINER, monocoil 7-1/4 long 1 I 1 1 1 I KIT, connector head tube (consisting of) INSULATOR, nut NUT, brass RING-HALF, gun GUARD, w/clamp (consisting of) CLAMP, 13/16-1-3/4clampdia 1 - 1 2 1 1 GUARD SCREW, 1 set socket hd 1/4-20 - x 1/4 1 HANDLE, gun 1 CUP, lubricator SCREW, set socket hd 10-24 x 1/4 SLEEVE, centenng ~.monocoil GUIDE, wire outlet f/16 & 5/64 wire GUIDE, wire outlet 3/32-1/8 wire CABLE/CONDUIT, 10 ft (consisting of) CABLE/CONDUIT, 15 ft (consisting of) ADAPTER, gun/feeder CLAMP, cable CLAMP, cable ADAPTER, head tube/power cable INSULATOR, body lubricator SPRING, compression LINER, monocoil 1/16-5/64 wire loft LINER, monocoil 3/32-1/8 wire lOft LINER, monocoil 1/16-5/64 wire 15 ft LINER, monocoil 3/32-1/8 wire 15 ft SCREW, flat-hd 1/4-20 X 3/8 FLUX HOPPER, hand-held (consisting of) COVER, flux hopper ~CLlP, spring-cover BODY, flux hopper LINER, monocoil 1/16-1/8 wire x 8-1/4 NOZZLE, flux SHIM, torch adapter (as reqd) ~ADAPTER, gun TUBE, head curved (consisting of) TUBE, fiber HINGE, cover NOZZLE, screw 1-3/4 long NOZZLE, screw 2-3/8 long ADAPTER, gun/feeder .045 wire COMPOUND, cable lubricant TRIGGER SWITCH, 10 ft TRIGGER SWITCH, 15 ft 1 I - 1 1 - 1 - 1 1 1 1 1 - 1 1 1 1 1 1 1 1 1 1 1 1 1 - 1 1 - 1 1 1 1 1 1 1 1 Optional Equipment +These items not included if unit was ordered with optional flux hopper factory installed. BE SURE TO PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT~ PARTS. OM-1532 Page 7 INSULATED WIRE GUIDES (Nozzles) Stock No. 046 013 1-3/4 (44 mm) long for 1-1/4 (32 mm) to 1-3/4 (44 mm) Elec trical Stick-Out CONTACT TUBES Stock No. 046 014 Wire Size Stock No. (1. 6 mm) .068/.072 (1.8 mm) 009 709 1/16 2-3/8 (6] mm) Stick-Out long for 2 (51 mm) to 2-1/2 (64 mm) Electrical 090 922 (2 mm) (2.4 mm) 052 055 008 926 THREAD PROTECTOR (Standard) Stock No. 046 017 7/64 (2.8 mm) 1/8 (3.2 mm) 008 925 008 924 REPLACEMENT LINERS 5/64 3/32 1 3/4 Insulated Wire Guide Stock No. Wire Size 1/16 3/32 lOft. (3 m) 15 ft. (4.6 m) (1.6 mm) and 5/64 (2 mm) (2. 4mm) through 1/8 (3.2 mm) 009624 048 823 009625 048 824 HAND-HELD FLUX HOPPER Stick No. 046 728 (Factory), 052 789 (Field) For manual Submerged Arc applications. NOTE: The head tube is not threaded and will not accept the insulated wire guides or thread pro tector. TRIGGER SWITCH 10 (3 m) Stock No. 079 855 15 (4.6 m) Stock No. 079 854 Includes cord and plug. Required when used with Swingarcs,TM PORTA~MIG,TM or the 50 Series feeders. 2 3 /8 Insulated Wire Guide