Download P81 Single Sided Vertical Electrophoresis System User Manual

Transcript

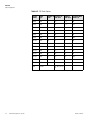

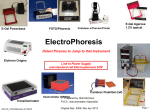

Single Sided Vertical Electrophoresis System P81 Operating and Maitnenance Manual 7007341 Rev. 0 Visit us online to register your warranty www.thermoscientific.com/warranty Preface MANUAL NUMBER 7007341 0 -- 5/3/12 Transfer to Marietta (was The Puffin 11/2002) REV ECR/ECN DATE DESCRIPTION Thermo Scientific By Vertical Electrophoresis System i Preface Important Read this instruction manual. Failure to read, understand and follow the instructions in this manual may result in damage to the unit, injury to operating personnel, and poor equipment performance. s Caution All internal adjustments and maintenance must be performed by qualified service personnel. s Warning To avoid the risk of personal shock, always disconnect the gel box from the power supply. Further, the power supply must be equipped with a shut-down-on-disconnect circuit. Running conditions for this unit should not exceed the name plate readings found on the lower buffer chamber. Do not move the unit unless the power source to the unit has been disconnected. s Statement of Proper Use: Use this product only for its intended purpose as described in this manual. Do not use this product if the power leads are damaged or if any of its surfaces are cracked. This Owl System is designed to meet IEC 1010-1 safety standards (IEC 1010-1 is an internationally accepted electrical safety standard for laboratory instruments). Material in this manual is for information purposes only. The contents and the product it describes are subject to change without notice. Thermo Fisher Scientific makes no representations or warranties with respect to this manual. In no event shall Thermo be held liable for any damages, direct or incidental, arising out of or related to the use of this manual. ©2012 Thermo Fisher Scientific. All rights reserved. ii Vertical Electrophoresis System Thermo Scientific Preface Important operating and/or maintenance instructions. Read the accompanying text carefully. Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol. Equipment being maintained or serviced must be turned off and locked off to prevent possible injury. Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be damaged by elevated temperatures. Marking of electrical and electronic equipment, which applies to electrical and electronic equipment falling under the Directive 2002/96/EC (WEEE) and the equipment that has been put on the market after 13 August 2005. This product is required to comply with the European Union’s Waste Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC. It is marked with the WEEE symbol. Thermo Fisher Scientific has contracted with one or more recycling/disposal companies in each EU Member State European Country, and this product should be disposed of or recycled through them. Further information on Thermo’s compliance with this directive, the recyclers in your country and information on Thermo products will be available at www.thermofisher.com. 4 Always use the proper protective equipment (clothing, gloves, goggles, etc.) 4 Always dissipate extreme cold or heat and wear protective clothing. 4 Always follow good hygiene practices. 4 Each individual is responsible for his or her own safety. Thermo Scientific Vertical Electrophoresis System iii Preface Do You Need Information or Assistance on Thermo Scientific Products? If you do, please contact us 8:00 a.m. to 6:00 p.m. (Eastern Time) at: 1-740-373-4763 1-800-438-4851 1-877-213-8051 http://www.thermoscientific.com [email protected] www.unitylabservices.com Direct Toll Free, U.S. and Canada FAX Internet Worldwide Web Home Page Tech Support Email Address Certified Service Web Page Our Sales Support staff can provide information on pricing and give you quotations. We can take your order and provide delivery information on major equipment items or make arrangements to have your local sales representative contact you. Our products are listed on the Internet and we can be contacted through our Internet home page. Our Service Support staff can supply technical information about proper setup, operation or troubleshooting of your equipment. We can fill your needs for spare or replacement parts or provide you with on-site service. We can also provide you with a quotation on our Extended Warranty for your Thermo Scientific products. Whatever Thermo Scientific products you need or use, we will be happy to discuss your applications. If you are experiencing technical problems, working together, we will help you locate the problem and, chances are, correct it yourself...over the telephone without a service call. When more extensive service is necessary, we will assist you with direct factory trained technicians or a qualified service organization for on-the-spot repair. If your service need is covered by the warranty, we will arrange for the unit to be repaired at our expense and to your satisfaction. Regardless of your needs, our professional telephone technicians are available to assist you Monday through Friday from 8:00 a.m. to 6:00 p.m. Eastern Time. Please contact us by telephone or fax. If you wish to write, our mailing address is: Thermo Fisher Scientific 401 Millcreek Road, Box 649 Marietta, OH 45750 International customers, please contact your local Thermo Scientific distributor. iv Vertical Electrophoresis System Thermo Scientific Table of Contents Thermo Scientific Section 1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 Unpack and Check Your Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 Section 2 Using the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 Running the Gel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 After the Gel Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Running Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Section 3 Technical Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 Acrylamide Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 Reagent Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 Offset vs. Notched Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3 Notched Alumina Plates - for P8DS Only . . . . . . . . . . . . . . . . . . . . .3-3 Combs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3 Section 4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1 Section 5 Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1 Section 6 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1 Vertical Electrophoresis System v Section 1 General Information The Single Sided Vertical Electrophoresis System is simple, rugged and provides excellent results. The upper buffer chamber (UBC) of the single sided vertical system extends the length of the gel to distribute heat evenly across the entire gel surface. Side clamps press glass plates against asilicome gasket to provide univlorm pressure and form a leak proof seal. This heat and pressure distribution system includes a notched alumina ceramic plate which may be used in front of the notched glass for cooler, faster runs. Unpack and Check Your Order Before starting, unpack the unit and inventory your order. If any parts are missing, contact Technical Services immediately. Reference the order or catalog number on your invoice and check the corresponding parts list. Table 1-1. Parts List Description Part Number Lid with attached Power Supply Leads - Upper Buffer Chamber - Lower Buffer Chamber - Blank glass plates 3/32" Thick P7-10G Size Notched glass plates 3/32" Thick Size Notched Alumina Plates 1.0mm Thick Size Thermo Scientific 10cmW x 10cmL P7-10R 10cmW x 10cmL P7-10RA 10cmW x 10cmL Spacers, 0.8mm Thick P7-SC Well Comb, 10 teeth, 0.8mm thick MP-10C Vertical Electrophoresis System 1-1 Section 1 General Information Table 1-2. Specifications Unit/Model Number P81 Gel size 10cmW x 10cmL & 10cmW x 8cmL Upper Buffer Chamber Capacity 100ml Lower Buffer Chamber Capacity 50ml Total Running Buffer 150ml Total Buffer Capacity 150ml Current, Constant 15-35mA/gel Time Requirements 30-90 min. Sample Capacity 10 Dimensions (cm) H x W x D 12.7 x 18.4 x 8.3 Glass Size (cm)W x L 10 x 10 Power Supply Leads Comb (2) Notched Alumina Plate Upper Buffer Chamber (UBC) Notched Glass Super Safe Lid Blank Glass Spacer Set Lower Buffer Chamber (LBC) Figure 1-1. Exploded Parts Diagram 1-2 Vertical Electrophoresis System Thermo Scientific Section 2 Running the Gel Using the System Note Owl offers a multiple gradient caster and a gel caster. See Section 6 for details. 1. After the gel is cast, place the gel with the notched or offset glass plate facing the inside of the upper buffer chamber. The gel cassette must be placed squarely on the corners in order to provide a good seal with the gasket and avoid leakage of buffer from the upper buffer chamber to the lower buffer chamber. 2. Add running buffer to the upper buffer chamber making sure the running buffer is 3mm below the top of the blank glass, ensuring sufficient contact with the top of the gel surface. Be sure that the running buffer is not leaking from the upper buffer chamber to the lower buffer chamber. If buffer is leaking, you will need to drain the UBC and reset the cassettes. 3. Remove combs by gently pulling straight up from the gel. Carefully load samples into the wells formed by the comb. Rinse wells with water. 4. Add buffer to the lower buffer chamber to approximately 2-3mm above the base of the gel using the fill line as a guide (max. fill). The bottom end of the gel/agarose assembly should be in contact with the running buffer. 5. Set the safety lid onto the unit so that the power supply leads are connected. Begin the gel run. Table 2-1. Maximum Buffer Volumes Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P81 Upper Buffer Chamber . . . . . . . . . . . . . . . . . .100ml Lower Buffer Chamber . . . . . . . . . . . . . . . . . . .50ml Thermo Scientific Vertical Electrophoresis System 2-1 Section 2 Using the System Running Conditions Running conditions depend on several parameters: • Buffer system used • Whether or not heating would affect subsequent processing of the proteins or gel • Thickness of the gel • How fast the gel will be run – for example, set it up in the late afternoon and have the gel done the next morning, or have it done in 45 minutes or less. A guideline for 2nd dimension gels - the range would be 30-80mA constant current. Example: For an SDS-PAGE gel in the P8DS that is 0.8mm thick and temperatures over 37°C are not an issue, 40mA per gel is appropriate. If the gel were 1.5mm thick, the setting could be 60mA or higher. Table 2-2. Recommended Running Conditions Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P81 Constant Current . . . . . . . . . . . . . . . . .15-35mA/gel Time Requirements . . . . . . . . . . . . . . .30-90 minutes After the Gel Run 1. Turn off power supply. 2. Remove the lid. Slide and lift the upper buffer chamber from the lower buffer chamber and drain buffer chambers separately. 3. Loosen wing knobs and slide side clamps to remove gel cassettes. The gel is ready for staining and blotting. Contact Technical Services or see the product catalog for additional staining and blotting accessories. 2-2 Vertical Electrophoresis System Thermo Scientific Section 3 Glass Technical Tips BLANK The plate which faces you during electrophoresis. All gel sandwiches require one piece of blank glass. BLANK NOTCHED The plate which faces the chamber during electrophoresis. Spacers are placed over the "ears" of the plate when casting vertical gels. Buffer accesses the gel between the ears. NOTCHED OFFSET Offset plates may be used in place of notched plates. They require sponge tips mounted on the spacers. Sponge tips take the place of the "ears", and prevent buffer from running out of the upper buffer chamber from the sides. OFFSET FROSTED Frosted plates are used for vertical agarose electrophoresis. One side of the plate has a rough surface to prevent agarose from sliding down. Spacers Thermo Scientific STANDARD Protein spacer sets include two side spacers and one bottom spacer. Spacers and combs must be of identical thickness to be used together. SPONGE TIP SPACER Vertical Electrophoresis System 3-1 Section 3 Technical Tips Reagent Information RUNNING BUFFER TGS Tris - 3.0285g/L Glycine - 14.4g/L SDS - 1.0g/L pH 8.3 (Laemmli, 1970) q.s. to 1L Note For Native Protein Electrophoresis, do not add SDS. s Table 3-1. Sample Buffer 2X Concentration Stock /L /10 mL Final Concentration With Sample* 2% SDS 20g 0.2 1% 10% BME 10mL 0.1 5% 250mM Tris 6.057g .0606g 125mM 30% Glycerol 300 mL 3 mL 15% 0.002% Bromo Phenol Blue .02g .0002g 0.001% * add sample buffer 1:1 with sample solution. Caution 2X Sample Buffer containing 2-mercaptoethanol should be prepared in a fume hood. 0.2M (final concentration) Dithiothreitol (DTT) may be used in place of 2-mercaptoethanol. DDT should be added before use and made fresh. s Acrylamide Solution Stock acrylamide solution for Table 3-2: = 29.2g Acrylamide and .8g bisAcrylamide, q.s. 100mL H2O Table 3-2. Gel Preparation (SDS-Page continuous buffer system) % Acrylamide* Stock Solution 20.0 15.0 12.5 10.0 5.0 Acrylamide-Bisacrylamide (30:0.8) 20.0 15.0 12.5 10.0 5.0 0.5 M Sodium Phosphate Buffer pH 7.2 6.0 6.0 6.0 6.0 6.0 10% (w/v) SDS 0.3 0.3 0.3 0.3 0.3 Water 2.2 7.2 9.7 12.2 17.2 1.5% (w/v) APS 1.5 1.5 1.5 1.5 1.5 TEMED 0.015 0.015 0.015 0.015 0.015 * The columns represent volumes (ml) of stock solutions required to prepare 30ml of gel mixture. 3-2 Vertical Electrophoresis System Thermo Scientific Section 3 Technical Tips Combs STANDARD • 0.5mm(A), 0.8mm (C) and 1.5mm (D) thicknesses PREPARATIVE • One long well and one marker lane Standard Preparative CUSTOM COMBS Call Technical Services for more information. Notched Alumina Plates - for P8DS Only Offset vs. Notched Glass Thermo Scientific Notched Alumina plates can take the place of the notched glass when casting and allows for better heat exchange than glass. This is important when the protein is heat sensitive or if a gel needs to be run a little faster without the negative effects of heating. Heating the gel during the run can cause smiling and other distortions of the gel. All units require a blank piece of glass and an offset or notched piece of glass. Offset glass is glass that is about 2cm shorter than the blank piece without "ears" on the sides. Notched glass has two "ears" that are left behind when a cut is made in the middle of the top of the glass. Both offset glass and notched glass allow the gel and samples to make contact with the upper buffer chamber. Offset glass has to be used with sponge tips, which take the place of the notches on the glass. The advantage of offset glass is that this glass is more rigid. Notched glass is easier to use and does not require the addition of sponge tips. SPONGE TIP SPACER Vertical Electrophoresis System 3-3 Section 4 Troubleshooting Problem Cause Solution Broad lanes at bottom of gel Will occur when adjoining lanes are loaded Normal in gradient gels with dissimilar samples. Gel has not polymerized properly at wells. Degas gel solution before casting and increase APS and TEMED concentrations. The comb can be wiped with TEMED just prior to casting to improve polymerization. Salt concentration is too high in sample. Dialyze sample or use desalting column. The upper buffer chamber is leaking either through the gel or along the sides. Check gel to make sure that it is a solid slab inside the glass and check the setup of the apparatus to ensure a secure seal with gasket. Overloading of sample. Use less protein or sample when loading. Sample has precipitated. Centrifuge sample before adding sample buffer or use a lower % acrylamide gel. Frowning of outside lanes Leakage of buffer along sides or along spacers inside the gel assembly. Do not move spacers after polymerization and make sure that gasket is seated firmly against the glass. Always load your samples with an empty lower buffer chamber so that leaks are caught before you begin the run. Double bands (“doublets”) If using a reducing agent, prepare fresh sample Due to reoxidation or insufficient reduction buffer every 30 days. Increase the concentration of the sample. of 2-mercaptoethanol or dithiothreitol in sample. Skewed bands Streaked bands Glass cracks when putting gel Gel is too thin for the clamping system. assembly in unit Use glass appropriate for the unit. If this is not possible, use an extra piece of blank glass to take up the space. If the clamps are used with their flat side against the glass, thinner glass may often be used. Wash gasket after each use to remove salts. If gasket is old and has lost its flexibility, it may Gasket is old or flattened making it impossi- need to be replaced. If unit has been previously ble to make a good seal. overtightened, the gasket may need to be removed and reseated. A cracked and dry gel often is an indicator of overheating. Thermo Scientific Vertical Electrophoresis System 4-1 Section 4 Troubleshooting Problem (continued) Cause (continued) Solution (continued) Buffer is too diluted Check buffer recipe; remake buffer and try again. See if voltage produced by the current you are running at is the same. If it differs significantly, your buffer may not have been made up correctly. Upper buffer chamber is leaking Make sure that the gel assembly is seated firmly against the gasket. Remove gasket, wash in warm water to remove excess salts, and place the gasket back in the groove. If the clamps have been overtightened in the past, the gasket can be pushed too far into the gasket groove and will not make a seal. Running at too low a current Use running conditions as stated in table 3-2. When running at constant current, the current value is per gel. Buffers are too concentrated Check buffer recipe; remake and try again. If voltage is lower than usual when running at constant current, the buffer is probably too dilute. Voltage or current set too high Turn down current setting Smiling of dye front Center of gel is running hotter than ends Turn down current setting Bands spreading outward Diffusion of sample when loading Make sure that the samples are loaded quickly and the power is applied as soon as possible after loading. Diffusion of sample during run in stacking gel Increase % of stacking gel or increase current by 25% when stacking. Lower ionic strength of sample Match the ionic strength of the sample with that of the gel. Longer run time Running too fast Bands are narrower than sample wells 4-2 Vertical Electrophoresis System Ionic strength of sample is higher than that Desalt the sample or use sample buffer of of the gel the same strength as the gel. Thermo Scientific Section 5 Care and Cleaning A few tips about caring for your system follow. Caution Organic solvents cause acrylic to “craze” or crack. Clean all acrylic systems with warm water and a mild detergent. Do not use ethanol or other organic solvents to clean these products. Do not autoclave, bake, or microwave your unit. Temperatures over 50°C can damage the acrylic. s Note If an RNase free electrophoresis system is desired, there are various methods to rid the system of RNA contamination. For fast and easy decontamination, use RNase Away®*. Spray, wipe or soak labware with RNase Away then wipe or rinse the surface clean; it instantly eliminates RNase. RNase Away eliminates the old methods that include treatment with 0.1% Diethyl Pyrocarbonate (DEPC) treated water and soaking in diluted bleach. DEPC is suspected to be a carcinogen and should be handled with care. This electrophoresis system should never be autoclaved, baked, or placed in a microwave. s To order RNase AWAY®, contact Technical Services: Part Number . . . . . . . . . . . . . . . . . . . . . .Description 7000 . . . . . . . . . . . . . . . . . . . . . . . . . . .250ml bottle 7002 . . . . . . . . . . . . . . . . . . . . . .475ml spray bottle 7003 . . . . . . . . . . . . . . . . . . . . . . . . . . .1 liter bottle 7005 . . . . . . . . . . . . . . . . . . . . . . . . . . .4 liter bottle *Rnase AWAY® is a registered trademark of Molecular BioProducts Thermo Scientific Vertical Electrophoresis System 5-1 Section 5 Care and Cleaning Care of Acrylic The following chemical compatibility chart is supplied for the convenience of our customers. Although acrylic is compatible with most solvents and solutions found in the biochemical laboratory, some solvents can cause substantial damage. Keep this chart handy to avoid harm to your apparatus by the use of an inappropriate solvent. Codes: S - Safe (no effect, except possibly some staining) A - Attacked (slight attack by, or absorption of, the liquid) (slight crazing or swelling, but acrylic has retained most of its strength) U - Unsatisfactory (softened, swollen, slowly dissolved) D - Dissolved (in seven days, or less) 5-2 Vertical Electrophoresis System Thermo Scientific Section 5 Care and Cleaning Table 6-1. Chemical Compatibility for Acrylic-Based Products Chemical Code Chemical Code Chemical Code Acetic acid (5%) S Ethyl alcohol (50%) A Naptha S Acetic acid (Glacial) D Ethyl alcohol (95%) U Nitric acid (10%) S Acetic Anhydride A Ethylene dichloride D Nitric acid (40%) A Acetone D Ethylene glycol S Nitric acid concentrate U Ammonia S 2-Ethylhexyl Sebacate S Oleic acid S Ammonium Chloride (saturated) S Formaldehyde (40%) S Olive oil S Ammonium Hydroxide (10%) S Gasoline, regular, leaded S Phenol 5% solution U Hydroxide (10%) S Glycerine Heptane (commercial grade) S Soap solution (Ivory) S Ammonium Hydroxide concentrate S Hexane S Sodium carbonate (2%) S Aniline D Hydrochloric acid (10%) S Sodium carbonate (20%) S Benzene D Hydrochloric acid concentrate S Sodium chloride (10%) S Butyl Acetate D Hydrouoric acid (40%) U Sodium hydroxide (1%) S Calcium chloride (saturated) S Hydrogen peroxide (3% solution) S Sodium hydroxide (10%) S Carbon tetrachloride U Hydrogen peroxide (28% solution) U Sodium hydroxide (60%) S Chloroform D Isooctane S Sodium hydrochlorite (5%) S Chromic acid (40%) U Isopropyl alcohol (100%) A Sulfuric acid (3%) S Citric acid (10%) S Kerosene (no. 2 fuel oil) S Sulfuric acid (30%) S Cottonseed oil (edible) S Lacquer thinner D Sulfuric acid concentrate U Detergent Solution (Heavy Duty) S Methyl alcohol (50%) A Toluene D Diesel oil S Methyl alcohol (100%) U Trichloroethylene D Diethyl ether U Methyl Ethyl Ketone U Turpentine S Dimethyl formamide U Methylene chloride D Water (distilled) S Dioctyl phthalate A Mineral oil (white) S Xylene D Ethyl acetate D This list does not include all possible chemical incompatibilities and safe compounds. Acrylic products should be cleaned with warm water, a mild detergent such as Alconox™, and can also be exposed to a mild bleach solution (10:1). In addition, RNAse removal products are also safe for acrylic. Contact Technical Services with any questions. Thermo Scientific Vertical Electrophoresis System 5-3 Section 6 Optional Equipment Contact the Technical Services department to order replacement parts. Table 6-1. Replacement Parts Thermo Scientific Description P81 Power Supply Leads PSL-5 Clamp Assemblies P8-CL Replacement Gaskets R12009 Blank Glass Plates 3/32” thick P7-10G, 10cmW x 10cmL Notched glass plates 3/32" Thick P7-10R, 10cmW x 10cmL Frosted Notched glass plates 3/32" Thick P7-10FR, 10cmW x 10cmL Frosted Blank Glass Plates 3/32" Thick P7-10FG, 10cmW x 10cmL Notched Alumina Plates 1.0mm Thick P7-10RA, 10cmW x 10cmL Spacers, 0.5mm Thick P7-SA Spacers, 0.8mm Thick P7-SC Spacers, 1.5mm Thick P7-SD Blocking Plate for Single Gel Operation P8DS-016 Spacer Placer (pkg of 3) JG4-PL Vertical Electrophoresis System 6-1 Section 6 Optional Equipment Table 6-2. P81 Comb Options 6-2 Vertical Electrophoresis System Catalog Number Comb Type Number of Thickness of Teeth Teeth (mm) Width of Teeth (mm) Estimated Well Volume (ul) MP-6A Well 6 0.5 11.1 89 MP-6C Well 6 0.8 11.1 142 MP6D Well 6 1.5 11.1 266 MP8A Well 8 0.5 7.7 62 MP-8C Well 8 0.8 7.7 99 MP-8D Well 8 1.5 7.7 185 MP-10A Well 10 0.5 5.7 46 MP-10C Well 10 0.8 5.7 73 MP-10D Well 10 1.5 5.6 134 MP-12A Well 12 0.5 4.3 34 MP-12C Well 12 0.8 4.3 55 MP-12D Well 12 1.5 4.3 103 MP-15A Well 15 0.5 2.9 23 MP-20A Well 20 0.5 1.6 13 XCM Custom 0.5, 0.8, 1.5, 2.0, 3.0 Thermo Scientific Section 6 Optional Equipment MULTIPLE GRADIENT CASTER The Multiple Gradient Caster System features an easy-to-use casting base and specially designed spacer plates for quick casting of high quality linear or gradient gels. Using the acrylic and foam spacer plates allows you to cast from one to five gels simultaneously. A silicone gasket provides a leak proof seal and the casting port allows the casting of gradient gels from the base of the caster. Rabbit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P7-CST Gel Size . . . . . . . . . . . . . . . . . . . . .10cmWX 10cmL GEL CASTER The patented Gel Casting System provides a simple method of casting acrylamide gels without taping or special sealing of the gel plates. Plastic pouches hold glass plates and spacers snugly together in the casting stand while pouring. These pouches meet specific measurement tolerances to allow for a tight fit around glass plates. Gels may be cast ahead of time and sealed inside the plastic pouch, creating your own pre-cast gels. Up to four gels may be cast at one time. Joey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .JGC-4 Gel Size . . . . . . . . . . . . . . . . . . . . .10cmWX 10cmL RELATED PRODUCTS • • • • • • Thermo Scientific Panther Semi-dry Electroblotter Puffin Single Sided Vertical Gel Electrophoresis System Bandit Tank Style Electroblotter Powdered Buffers Silver Stain Pro Blue Vertical Electrophoresis System 6-3 Thermo Scientific Rev. 0 9/12 REGISTERED ISO 9001 If equipment service is required, please call your Technical Services Department at 1-800-438-4851 (USA and Canada) or 1-740-373-4763. We’re ready to answer your questions on equipment warranty, operation, maintenance, service, and special applications. Outside the USA, contract your local distributor for warranty information. Your local Thermo Sales Office is ready to help with comprehensive site preparation information before your equipment arrives. Printed instruction manuals carefully detail equipment installation, operation and preventive maintenance. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR IMPLIED. NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. Thermo shall not be liable for any indirect or consequential damages including, without limitation, damages to lost profits or loss of products. Replacement or repair of component parts or equipment under this warranty shall not extend the warranty to either the equipment or to the component part beyond the original warranty period. The Technical Services Department must give prior approval for return of any component or equipment. At Thermo’s option, all non-conforming parts must be returned to Thermo postage paid and replacement parts are shipped FOB destination. During the first thirty-six (36) months, component parts proven to be non-conforming in material or workmanship will be replaced at Thermo’s expense, including labor. Installation, calibration and certification is not covered by this warranty agreement. The Technical Services Department must be contacted for warranty determination and direction prior to performance of any repairs. Expendable items, glass, filters and gaskets are excluded from this warranty. The Warranty Period starts two weeks from the date your equipment is shipped from our facility. This allows shipping time so the warranty will go into effect at approximately the same time your equipment is delivered. The warranty protection extends to any subsequent owner. THERMO FISHER SCIENTIFIC OWL PRODUCTS WARRANTY USA Section 7 Warranty Information Vertical Electrophoresis System 7-1 7-2 Vertical Electrophoresis System Rev. 0 9/12 REGISTERED ISO 9001 If equipment service is required, please call your Technical Services Department at 1-800-438-4851 (USA or Canada) or 1-740-373-4763. We’re ready to answer your questions on equipment warranty, operation, maintenance, service, and special applications. Outside the USA, contract your local distributor for warranty information. Your local Thermo Sales Office is ready to help with comprehensive site preparation information before your equipment arrives. Printed instruction manuals carefully detail equipment installation, operation and preventive maintenance. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR IMPLIED. NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. Thermo shall not be liable for any indirect or consequential damages including, without limitation, damages to lost profits or loss of products. Replacement or repair of component parts or equipment under this warranty shall not extend the warranty to either the equipment or to the component part beyond the original warranty period. The Technical Services Department must give prior approval for return of any component or equipment. At Thermo’s option, all non-conforming parts must be returned to Thermo postage paid and replacement parts are shipped FOB destination. During the first thirty six (36) months, component parts proven to be non-conforming in material or workmanship will be replaced at Thermo’s expense, excepting labor. Installation, calibration and certification is not covered by this warranty agreement. The Technical Services Department must be contacted for warranty determination and direction prior to performance of any repairs. Expendable items, glass, filters and gaskets are excluded from this warranty. The Warranty Period starts two months from the date your equipment is shipped from our facility. This allows shipping time so the warranty will go into effect at approximately the same time your equipment is delivered. The warranty protection extends to any subsequent owner. THERMO FISHER SCIENTIFIC OWL PRODUCTS WARRANTY INTERNATIONAL Section 7 Warranty Information Thermo Scientific Thermo Fisher Scientific 401 Millcreek Road Marietta, Ohio 45750 United States www.thermofisher.com