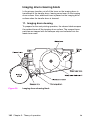

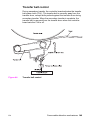

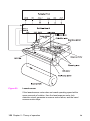

Download Color LaserJet 8500

Transcript