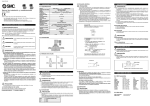

Download Simplified Manual

Transcript