Transcript

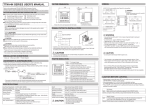

和文の説明は裏面にあります。 OPERATION FLOW AND SETTING MENU TTM-000 SERIES USER'S MANUAL 1 /16 DIN. DIGITAL TEMPERATURE CONTROLLER ●Power ON CAUTION : Press key Set the temperature required MODE key MODE key more than 2 seconds MODE key, return to A ●FUNC key FUNK key operates on the selected setting mode 7. Refer to Ex.2. Ex.1. MODE key 2. Input type setting Select input type Refer to Table 1. B. Priority displays. Refer to Ex.1. SET0 : Priority displays by setting and shows max.9 displays by setting. a correct model (See the following "Model Configuration" ). ●The following symbol marks provide to prevent incident or damage. Kindly refer to the details of the WARNING/CAUTION when using for the first time. ●Another copy of the user's manual "Advanced Version" is provided at customer's request. Owing to mishandling, it may cause some damage to the unit or the operator getting slight injury. Primary displays Process value Setting value ●When having the purchased controller at hand, please be sure that its unit is WARNING Initial setting mode Calling display ●Operate mode display A. NOTICE/WARNING BEFORE OPERATION USE Due to mishandling, serious dangers may occur to the operator such as death, electrocution and a skin burn. <SET1:Initial Setting> 1. Initial setting display Shows for 4 seconds (Warming up) Thank you for purchasing model TTM-000 SERIES Digital Temperature Controller. Please go through this Instruction Manual carefully and use the unit in proper manner. Priority displays & its setting This function is to shift the most essential screens on setting mode into operation mode as a priority. Please select priority displays through priority display setting. eg. : Basic display Output 1 manipulated value Setting high limit for event Output 1 CAUTION WARNING ●Make sure the correct wiring connection before turning on electricity. Mis-wiring may cause malfunction of the unit and fire. ●Never modify the unit to prevent damage or incident such as malfunction and fire etc. ・Please put this user's manual aside for your reference, when operating the unit. ・Copy or reprint of this manual, wholly or partially, is not allowed. ・The contents of this manual may change without notice in future. ACCESSORY & CONFIGURATION 1) Please be sure that the unit enclosed in packing carton is a right model before using. 2) Kindly check the following accessory being contained in that carton box. ● Installation Attachment (For installation, please see "INSTALLATION AND WIRING" on the back.) ● This user's manual : 1 copy 3) Model Configuration Model Input Output 1 Option T T M - □ □ □ −□ −□ −A □ □ □ MODEL Front Dimensions 002 24×48 mm 004 48×48 mm X04 48×48 mm 005 96×48 mm 006 48×96 mm 007 72×72 mm 009 96×96 mm CODE Input Type NIL Thermocouple (K, J, R, T, N, S, B) R.T.D. (Pt100, JPt100) 2 0–5V, 1–5V, 4–20mA CODE Output 1 R Relay contact P SSR drive voltage I Current 4–20 mA DC Option CODE B Output 2 Relay contact B or P selectable P Output 2 SSR drive voltage R EV 2 Relay contact Not optional for TTM-002/004. When DI is selected for TTM-005, 006, 007 or 009, this option is not available. D CT input When DI is selected for TTM-002/004, this option is not usable. When I output (4–20mA) is selected, this option is not provided. E DI (Digital input) When CT is selected for TTM-002/004, this option cannot be obtained. When EV 2 is selected for TTM-005, 006, 007 or 009, this option cannot be chosen. M Communication RS-485 * A (EV1) provided in the standard specifications. * Without output 2, EV2 is not available. * Output 2 is equally used as EV2, but both not activated simultaneously. Control Output Control Method Operation Environment Storage Environment Weight Location of the Unit Setting CAUTION Installation condition Ex.3. To select PID Feature of type A and B Type A Ordinary PID Type B Over shoot protection PID If control is unstable under self-tuning, please change to type A or B and also to ON/OFF control. Ex.4. ● ● ARW Anti-reset wind-up take effect for overshooting by over-integral of PID control action. ARW controls integral action(PV accords with SV). If integral value goes down, it takes effects. If integral value is set "0", it stops integral action. Table1. To select input sensors and setting range. unit:℃ 0.0 Setting Symbol Low limit∼High limit 00 K Thermocouple − 200∼1372 −199.9∼990.0 01 J 〃 − 200∼ 850 −199.9∼850.0 02 R 〃 − 0∼1700 03 T 〃 − 200∼ 400 −199.9∼390.0 04 N 〃 − 200∼1300 −199.9∼990.0 05 S 〃 − 0∼1700 06 B 〃 − 0∼1800 10 Pt100 − 199∼ 500 −199.9∼500.0 11 JPt100 − 199∼ 500 −199.9∼500.0 20 DC0 – 5V −1999∼9999 −199.9∼999.9 −19.99∼99.99 −1.999∼9.999 21 DC1 – 5V −1999∼9999 −199.9∼999.9 −19.99∼99.99 −1.999∼9.999 22 DC4 – 20mA −1999∼9999 −199.9∼999.9 −19.99∼99.99 −1.999∼9.999 <SET3:Event Output 1> 37. Event output 1 setting EV1 setting mode Calling display ▼ KEY MODE key 10. High limit setting in SV limiter MODE key 38. Function setting for EV 1 Display of high limit setting * Current/Voltage of setting value. 「9000」 (Within setting range of Table 1) Select below functions. MODE key 11. Low limit setting in SV limiter Display of low limit setting * Current/Voltage of setting value. 「−1000」 (Within setting range of Table 1) MODE key 4. Zero point setting for PV correction MODE key 12. Control mode setting When measurement value comes an error, set the correction value (Addition) Usable for control mode setting MODE key 5. Filtre input Control performance Non-control performance (Manipulated value low limiter output) CR filter effect is operational on software when making first-order lag operation to process value (PV). Manual control MODE key 13. Selection of control type setting MODE key 6. Position of decimal point Not required Required Current/Voltage PID, Refer to Ex.3. Not required 1 digit 2 digits 3 digits 0:Type A 1:Type B Control output 1 1:PID 2:ON/OFF Control output 2 0:None 1:PID 2:ON/OFF 3:Event output MODE key 14. Change of normal or reverse MODE key 7. FUNK key setting (Refer to Ex.2.) Key lock setting for protection of error operation. Selectable below functions None All lock Operation mode lock only Except operation mode Set high limit value. Set high limit value. MODE key 40. Low limit setting for EV 1 MODE key 50. Low limit setting for EV 2 Set low limit value. Set low limit value. MODE key, return to 1 MODE key 17. AT coefficient setting Coefficient is multiplied by proportional band value computed at auto-tuning. MODE key 18. AT sensitivity setting Sensitivity is set up during ON/OFF control at auto-tuning, particulary when PV is fairly unstable. MODE key 19. Proportional band setting for output 1 Adjusts proportional band for output 1 (% per SLL ∼SLH) MODE key 20. Integral time setting Adjusts integral time 0∼3600 (second) Adjusts deviative time 0∼3600 (second) (19. To Set multiple of output proportional band) MODE key 28. Proportional cycle setting for output 2 100 to 240V AC, 50/60Hz Below 10 VA EEPROM Thermocouple, R.T.D./0–5V, 1–5V, 4–20mA (Changeable by front key) Relay contact, SSR drive voltage, Current Two kinds of PID, ON/OFF 0 to 50℃, 20 to 90%RH (Avoid making dew) −25 to 70℃, 5 to 95%RH (Avoid making dew) TTM-002/004 Less than 180g, TTM-005/006 Less than 240g, TTM-007 Less than 250g, TTM-009 Less than 310g. Keep away from the followings. ・Gas of corrosion, dust and oily smoke. ・The electric noise of generator. ・The influence of electromagnetic field. ・Mechanical vibration and shock. ・The direct sunlight. Installation category2 Conformed Standards Safety : EN61010-1(IEC1010-1) EMI : EN50081-2 EMS : EN50082-2 UL3121-1(UL /CUL) MODE key 56. Abnormal current value of heater for EV 2 Setting for current value when heater is abnormal. 1∼30A MODE key, return to 37 MODE key, return to 47 MODE key 31. Manual reset setting Select below polarity. BCC check None Available Close action Open action MODE key 63. Speed setting MODE key 60. Setting for SV2 Displays only when SV2 is selected at DI.(℃) MODE key 32. Dead band Setting <When select ON/OFF Control> 33. Contorol sensitivity setting for output 1 Adjusts control sensitivity of ON/OFF control for output1. MODE key 34. OFF position setting for output 1 For setting OFF position of control output1. MODE key 35. Contorol sensitivity setting for output 2 MODE key 24. High limit setting of manipulated value for output 1 Adjusts control sensitivity of ON/OFF control for output2. For setting of manipulated high limit value. (output 1) (%) MODE key 36. OFF position setting for output 2 MODE key 25. Low limit setting of manipulated value for output 1 For setting OFF position of control output2. *When output 2 is ON/OFF, go to 35. Timer setting mode Calling display Select priority displays Calling display (Refer to Ex.1.) ▼ MODE key 68. Timer output setting Non-use Control output Event 1 output MODE key 69. Timer function setting Auto start Manual start Event start Auto start Manual start Event start SV start (ON delay) (ON delay) (ON delay) (OFF delay) (OFF delay) (OFF delay) (OFF delay) MODE key 70. Timer unit selection 1200bps 2400bps 4800bps 9600bps 19200bps MODE key, return to 57 Hour/minute Minute/second MODE key 71. Timer SV start permissible range MODE key 64. Address setting Setting range : 1∼99 MODE key 65. Response delay time setting Setting range : 0∼250mS MODE key 66. Mode selection setting R communication RW communication MODE key, return to 61 NO. MODE key 75. Setting for 1st priority display MODE key 2nd display Thermocouple/R.T.D.(Pt100, JPt100) Input Setting range : 0∼999 0.0∼999.9 Setting unit : ℃ Current/Voltage Input Setting range : 0∼9999 (Decimal point at designated position) Setting unit : digit MODE key 76. Setting for 2nd priority display MODE key 3rd display Select 2nd display on operation mode B. NO. MODE key 77. Setting for 3rd priority display MODE key 4th display Select 3rd display on operation mode B. NO. MODE key 78. Setting for 4th priority display MODE key 5th display Select 4th display on operation mode B. NO. MODE key 79. Setting for 5th priority display MODE key 6th display Select 5th display on operation mode B. NO. MODE key 80. Setting for 6th priority display MODE key 7th display Select 6th display on operation mode B. NO. MODE key 81. Setting for 7th priority display MODE key 8th display Select 7th display on operation mode B. NO. MODE key 82. Setting for 8th priority display MODE key 9th display Select 8th display on operation mode B. MODE key 72. Timer time setting Setting range : 0:00∼99:59 0:00∼59:59 NO. NO. MODE key 83. Setting for 9th priority display MODE key 73. Timer residual time monitor setting Residual time monitor. Timer starts when pressing FUNC key. MODE key Return to primary display Select 9th display on operation mode B. MODE key, return to 74 MODE key, return to 67 ●How to release BLIND Function eg. Release of Timer Setting Mode from BLIND Function before newly its set-up. 1. Power ON Automatically taking 4 sec CAUTION ERROR MESSAGES AND TROUBLE SHOOTING (Description) (Trouble Shooting) Shown whenever input value exceeds the high limit of display range. Also displays when the wire thermocouple, ABb terminal of R.T.D is snapped off. Shown whenever input value exceeds the low limit of display range. Check the snapping of thermocouple and R.T.D. input. Display of memory error. In case this indication shows after the reinput of power, replace unit if it persists. For shifting proportional band. For heating and cooling control(℃). ▼ 2. Initial Display Automatically 3. Operation Mode Press MODE Key (10 sec) 4. Immediately after the "Blink", press FUNC Key, and quickly press MODE Key. 5. Press MODE Key (3 sec) (Display) For setting of manipulated low limit value. (output 2) (%) MODE key 23. ARW setting (see Ex. 4) 6. Press UP Key (△) for 1 7 Check short circuit of input lines between A-B and A-b R.T.D. 7. Press FUNC Key for OFF ON Display of A/D converter error or incorrect sensor connection with selectable input. Ditto Display of auto-tuning error. Check sensor connection or change to other tuning. **1 **2 **3 8. Power OFF 9. Power ON Automatically taking 4 sec Displayed when parameter is changed in key-lock condition. Discontinue to change parameter. 10. Initial Display Automatically Alternately this and SV/PV display are shown. Normality 11. TIMER Setting Mode (OPERATION Mode) Press MODE Key (2 sec) Displayed when setting value is changed on SV2 control. Discontinue to change setting value (during control of SV2) Displayed when changing setting value of shift on DI. Discontinue to change setting value of the self on digital input Displayed when making setting value change in control display while function key is on RUN/READY. Discontinue to change setting value Displayed when altering setting value in control display while being on timer. (Blink once) 12. Press UP Key (△) for 1 7 13. Go on TIMER Setting Press MODE Key consecutively **1 Please select an appropriate charactor (eg. Timer Setting etc) being of BLIND Function effect for the demanding release. **2 Charactor selected for TIMER Setting. **3 BLIND Function for "SELECTION DISPLAY (Timer Setting Mode)" is released. MODE key, return to 9 ※See also "PARTS INDICATION" & "INSTALLATION AND WIRING" on the reverse. CAUTION BEFORE CONTROL program is stored after power OFF, as non-volatile memory is equipped with TTM-000 SERIES controllers for setting storage. ●Either thermocouple or R.T.D.(Pt 100/JPt 100) is selectable input type, but Current/Voltage input needs to be selected individually. For suitable application, please select most appropriate input type and adjust input setup. ●PID or ON/OFF control is selective for the optimal performance and each detail of features is specified in the table on the right side. Data length 7 bit 8 bit MODE key 59. Polarity setting for DI MODE key 55. CT Input Monitor or EV 2 Setting for current value when heater is abnormal. 1∼30A For setting of manipulated high limit value. (output 2) (%) Adjusts proportional cycle time 1∼120 (second) MODE key Parity check Nil Odd number Even number Normal open/close is selectable while event output is ON. Normal open Normal close MODE key 46. Abnormal current value of heater for EV 1 MODE key 30. Low limit setting of manipulated value for output 2 MODE key 22. Proportional cycle setting for output 1 For setting of manipulated low limit value. (output 1) (%) Stop bit length 1 bit 2 bit DI action SV2 READY Manual Normal AT start Normal SV2 Timer start MODE key 29. High limit setting of manipulated value for output 2 Adjusts ARW by % 0.0∼100.0% (−10.0∼110.0%) ●Setting ●Selection memo for priority displays. Display NO. for record, 1st display <SET0:Priority Displays> ▲ 74. Priority displays setting Select 1st display on operation mode B. MODE key 54. Polarity setting for EV 2 Monitors current value of heater current detector. 1∼60A Adjusts proportional cycle time 1∼120 (second) SV RUN AUTO Reverse AT release Reverse SV Reset For outbreak of sensor and heater abnormal Monitors current value of heater current detector. 1∼60A <SET7:Timer> ▲ 67. Timer setting Select below functions. Set delay timer when required(sec). 0:None 1:PV abnormal (sensor break) 2:Heater abnormal 3:PV + Heater abnormal Action 0:None 1:Hold (Power reset) MODE key 45. CT Input Monitor for EV 1 Adjusts proportional band. MODE key 62. Parameter setting for communication MODE key 52. Delay timer setting for EV 2 0:None 1:PV abnormal (sensor break) 2:Heater abnormal 3:PV + Heater abnormal Action 0:None 1:Hold (Power reset) Communication setting mode Calling display ▼ MODE key 58. Function setting for DI Set sensitivity when 。 required(C ). Type Normal open/close is selectable while event output is ON. Normal open Normal close MODE key 27. Proportional band setting for output 2 Auto-tuning : Select above ・ or and press FUNC key once. Call off autotuning : press FUNC key once on operating. DI setting mode Calling display ▼ MODE key 51. Control sensitivity setting for EV 2 Type MODE key 44. Polarity setting for EV 1 Shows process manipulated value for output 2, and setting the value on manual control. Display range : 0.0∼100.0% (−10.0∼110.0%) Setting range : Manipulated value low/high limiter <SET6:Communication> ▲ 61. Communication setting MODE key 53. Abnormal for EV 2 For outbreak of sensor and heater abnormal <When select PID control> 16. Setting for PID tuning type 26. Manipulated value for output 2 (%) Auto-tuning output 1 Self-tuning output 1 Auto-tuning output 2 Self-tuning output 2 Auto-tuning output 1.2 Additional Event functions 0:None 1:EV output hold 2:Stand-by sequence 3:EV output hold & stand-by sequence MODE key 49. High limit setting for EV 2 MODE key Tunes suitably for setting value. Additional Event functions 0:None 1:EV output hold 2:Stand-by sequence 3:EV output hold & stand-by sequence MODE key 43. Abnormal for EV 1 Shows process manipulated value for output 1, and setting the value on manual control. Display range : 0.0∼100.0% (−10.0∼110.0%) Setting range : Manipulated value low/high limiter MODE key 8. Key lock setting PV Event functions MODE key 41. Control sensitivity setting for EV 1 <SET5:Digital Input> ▲ 57. DI setting Select below functions. 0:None 1:Deviation high and low limit 2:Deviation high limit 3:Deviation low limit 4:Deviation high and low limit range 5:Absolute value high and low limit 6:Absolute value high limit 7:Absolute value low limit 8:Absolute value high and low limit range Set delay timer when required(sec). MODE key 15. Manipulated value for output 1(%) EV2 setting mode Calling display MODE key 48. Function setting for EV 2 PV Event functions MODE key 42. Delay timer setting for EV 1 0:Reverse (Heating) 1:Normal (Cooling) None Change of digit RUN/READY Auto-Tuning Timer ▼ 0:None 1:Deviation high and low limit 2:Deviation high limit 3:Deviation low limit 4:Deviation high and low limit range 5:Absolute value high and low limit 6:Absolute value high limit 7:Absolute value low limit 8:Absolute value high and low limit range Set sensitivity when 。 required(C ). Switchable below control output actions. Selectable below functions <SET4:Event Output 2> ▲ 47. Event output 2 setting MODE key 39. High limit setting for EV 1 Selectable and switchable below control modes. Thermocouple/R.T.D.(Pt100, JPt100) MODE key 21. Deviative time setting *Either thermocouple or R.T.D. (Pt 100/JPt 100) is selectable for input type, by pressing the front key. *Either "B" or "P" is optional. *A (Event 1) : Single alarm is provided in the standard specifications. Control setting mode Calling display ▼ KEY * After select, press MODE key * Current/Voltage 「22」 ▲ KEY From 25. SPECIFICATIONS Power Supply Voltage Power Consumption Memory Element Input of Sensor FUNC key work This function is to enable FUNC key to use as a specific key, for the following actions selected in FUNC key setting belonged to setting mode. 1.Digit shift Setting digit shift is enabled when setting value is changed. 2.RUN/READY Control stop (READY) and control performance (RUN) are alternately switched every time FUNC key is pressed. (READY lamp is ON during control stop) 3.Auto-Tuning (AT) AT starts instantly after pressing FUNC key. (Start/Reset operation is available, each time FUNC key is pressed) 4.Timer Available for start/reset. <SET2:Control Setting> 9. Details of control setting When measurement value comes an error, set the correction value (Multiplication) Ex.2. prevention of its malfunction, do not push the front key with sharp points. ●Spare terminal must not be used for other purposes. ▲ KEY MODE key 3. PV correction gain *Screen is shifted when pressing mode key each time. ●For Setting display shows the existence of option. ●Setting mode PID Control ON/OFF Control Merit Better control result is achieved Life span of relay is generally longer, as opposed to that of ON/OFF control. as it is ON when temperature is below SV and it is OFF when temperature is over SV (For heating control). Demerit Life span of relay is shorter, as output Control value is worse in comparison exists frequently with relay contact . with that of PID control. ※ PID constants are automatically reckoned up to write in, when control begins or SV is altered on self-tuning. TOHO ELECTRONICS INC. Head office: 1-13-21, Tanashioda, Sagamihara Kanagawa 229-1125 Japan. Phone: +81-42-777-3311 Fax: +81-42-777-3751 E-Mail: [email protected] Web site: http://www.toho-inc.co.jp