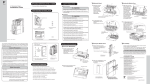

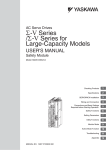

Download User Manual

Transcript