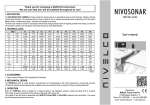

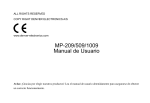

Download USER`S AND PROGRAMMING MANUAL

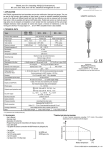

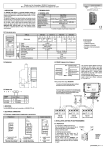

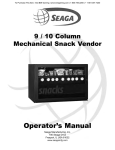

Transcript