Download LVDT - Newmark Structural Engineering Laboratory

Transcript

CIVIL & ENVIRONMENTAL ENGINEERING

MANUALS

Instrumentation.

eb.30.10.02

NSE.L

CUtr.E

UWUC

Linear VariableDifferentialTransformers:

Theorv.Instrumentation

andInstallation

Prepared

by: Grzes.otzBanas and Can Simsrr

Sponsored

by: Newmark StructuralEngineeringLaboratory

Departmentof Civil & Environ. Engineering

Collegeof Engineering

Universityof Illinoisat Urbana-Charnpaign

U r b a n aI,l l i n o i s6 1 8 0 1 - 2 3 9 7

October,2002

INTRoDUCTIoN

The purposeof this rnanualis to provide the basic principlesof theory and installation

associatedrvith linear variable diffcrcntial transfbrmersto users of the Nervmark Structural

EngineeringLaboratory(NSEL). The materialpresentedin this manualis basedon 50 yearsof'

ofpast

listedat the endof thisnranual.Also, the experience

expcrience

ofNSI:L and ret'erences

qucstions

have

askcd

on

Many

been

*as

u,hile

working

on

this

manual.

usersol'NSEL

used

wererecomrrendedin rvhichansu'crscould

rlhich eitlierdirectansu'ersrveregivcn or ref-erences

fon.nat. Any

be tbund. That is w'hy this manualwas partially rvrittenin thc question-ansu'er

criticalcommentsand remarksof currentuscrsare also welcomcdand they rvill be usedin a

and

future revision. This manual is divided into threc scctions:Theory, lnstrumentation,

Installation.

I HEORY

What is a lincar variabledit-ferential

transforrner?The linear variablc dill'erential

of

rvhich allolvs the measurement

transducer,

transfbrmer(LVDT) is an elcctromcchanical

displacernent

of any movablepafi. The measuredamountof displacementis proportionalto the

elcctricaloutput of the transduceras a resultantof an inductiveinteractionbetrvccna magnetic

core and a set of windings: prinraryrvindingwhich is polveredby high frequencylorv voltage

'fhc

current,and trvo secondaryrvindingsusuallysymrnetricallylocatedagainstthe primary one.

secondarywindingsgeneratethc electricaloutputcorrelatedto the positlonof the magncticcore.

Figure I shorvsan examplcof a commonlyusedLVDT. The primary rvinding (8) and

the secondaryu,indings(9) are separated

by high-densityglossfilled polyrnercoil fbrm (4) and

'fhis

in cpoxy (3).

assemblyis covcrcdby stainlesssteelhousing(l),

both are encapsulatcd

sleeve(6), and end caps(5). The h igh-pcrneabilitymagneticshell (2) is placedbetweenthc

'l'he

(3), and separators

(zl).

nickelhigh-permeability

housing(l), and polyrnerencapsulation

(6).

sleeve

Carricr(10),

(7),

is

placed

inside

of

the

usuallythreadedfiom both ends,

iron core

rvhich must bc non-magnetic,

transfersthe linear motion of an object to the core (7) and

changestlie electricaloutputof the [-VDT.

consequently

Horv doesthe I-VDT work? Figure2 illustrateswhat happcnsrvhenthe core of'the

by a

LVDT is in differentaxialpositions.The primaryrvinding,(P) o1'theLVDT is energized

(AC)

is

coupled

by

source.The magneticflux thus developed

constantamplitudcalteredcurrent

(Sr) and (Sz). If the core is locatcdmidivay

tlie core to the adjaccntsecondaryr.vindings,

(S1) and (S2)(Figure2b), equalmagneticflux is coupledto eachsecondarywinding so

bctr.veen

the voltages,(E1) and (82) inducedin eachwindingare equal. At this midrvaycoreposition,

voltageoutput,(Er - Ez) is ellectivelyzcro. As

to as the null point,the difl'erential

ref-errsd

rvhile

shorvnin Figure2a, if the coreis movedcloserto (Sr), the inducedvoltage(Ey) incrcases

if the coreis moved

(E2)decreases,

voltage(Er E:) Conversely,

resultingin the diff-erential

(52)

(S1),

(E2)is incrcased

as

and

and lessto

closerto (S2)(Figure2c), more11uxis coupledto

(E1)is decreased,

voltage(E: - Er). Figure3a showsthe n.ragnitude

resultingin the differential

ofthe diff'erentialoutputvoltage(Eecour)variesrvith coreposition. The valueof E466u1at

of an LVDT: l. Stainless

steelhousing,2. H igh-permeability

Fig. I Half'-viewhalf--cross-section

.1.High-density

glossfilled polyrnercoil forrn,5. Stainless

magneticshell,3.Epoxyencapsulation,

on bothends,

nickel-ironcorethreaded

stcelendcaps,6. Stainless

steelsleeve,7. I Iigh-perrneability

rvinding,10.Non-magnetic

carrier.

8. Primaryrvinding,9. Secondary

E o u t: E t - E :

Eout: El- E2-0

E o u t : E 2- E l

Max left

behveencoreand rvindingsin an LVDT: a) Coreis in

Ifig.2 Schernatic

diagramofan interaction

the maximumlefi positionat rvhichvoltage(E,1)is higherthan(E2)due to the higherf'luxcoupled

betweenprimary u,inding(P) and secondaryrvinding(Sr), b) Core is in the midrvaybetrvccn

sccondaryrvindings(Sr) and (S2);thus equal f'lux is coupledto each secondarywinding and

Er : E:, c) Core is in the maximum right positionat rvhichvoltage(82) is higherthan

consequently

(Er) due to the highcrflux coupledbetweenprirnaryrvinding(P) and secondaryrvinding(S2).

Fig. 3 Output from LVDT: a) Magnitudeof differentialAC output,b) Phaseangle

ofoutput relativeto primary,c) Magnitudeof DC outputfiom signalconditioner.

from null dependsupon the amplitudco1'theprimaryexcit;.ttion

nlaximumcore displacement

voltagcand thc scnsitivityfactorof the particularLVDT, but is typicallyscvcralvolts (rms).

to the primary excitationvoltage,stays

The phaseangleof the AC output (E,rcout),ref-erenced

constantuntil the centerof the corepassesthe null poilt, rvherethc phaseanglechangesabruptly

the

by 180",as shou'ngraphicallyin Figure3b. This 180' phaseshift canbc usedto determine

directionof the core positionliom the null by meansof appropriatecircuitry. This is shown in

the positionof thc core

Figure3c, where the polarity of the output signal(Ep6) represents

relativeto the null point. It is apparentfrom this figurc that the output lrom the LVDT is linear

over its specifiedcoremotion,and that the sensorcan bc usedover an extendcdrangewith some

reductionin outputlinearity.

'I'he

of using an LVDT as opposed

What arc the benefitsol usingan LVD'f?

advantages

can be listcdas fbllorvs:

to otherdisplacement

transducers

o

Friction-FreeOperutit.trt:

Thereis no mcchanicalcontactbetweenthe core and coil assembly

liG. Furthcmore,thc absence

of the LVDT, which meansit features

unlirnitedmcchanical

of friction permitsthc LVD-I' to respondvery last to changcsin core position. Only thc

of thc LVD'l'sensor.

inertialeffectsof the slightmassof the corelimit thc dynamicresponse

lnfinite Resolution:LVDT is an absoluteoutputdevice,as opposedto an incrementaloutput

inlinitesirnally

small changesin core positionbecauseit operateson

devrce. It measures

and outputdispiaylimit the

electromagnetic

couplingprinciples.Only the signalconditioner

intlnitcrcsolutioncapabilityof thc LVDI . Also due to this capability,the locationof the

intrinsicnull pointofthe LVDT is cxtremclystablcandrepeatable.

Single Aris Sensitivi4t:LVDT respondsto motion of the core along the coil axis, but it is

insensitiveto radial positionof the corc. Thcrelbrethe LVDT still functionswithout a

problemwhen thc core is misalignedand doesnot travel in a precrselystraightlinc.

SeparableCoil and Core: 1'hc coil asscmblycan be isolatedfion.rthe core by insefiinga

non-magnetictube betweenthe core and the bore. This tube can containa pressurizedfluid

ri,hen,fbr example,thc LVD] is uscdfbr spoolpositionfeedbackin hydraulicservovalves.

Over-travelDantage Resistant:The intemal bore o1'mostLVDTs is open at both ends. In

the eventof unanticipatcdover-travel,the core is able to passcompletelythroughthe sensor

coil assemblyrvithoutcausingdamagc.

to moistureand humidity,as wcll

LVDTs havesuperiorresistance

EnvironmentallyRr.;Drrsl:

'fhe

internalhighvibration

lcvels

in all axcs.

as to substantialshock loads and high

permcabilitymagneticshieldminirnizesthe efTcctsof extemalAC fields. The caseand core

are corrosionrcsistantand they can be hermeticallysealedusing a variety of rveldtng

processes.LVDTs can operateover a very rvide temperaturerange, tiom cryogenic

and radiationlevelsfound in many nuclearreactors.

temperatures

to elevatedtempcraturcs

)

What is the differencebetween(AC-AC) LVDT and (DC-DC) LVDT'I Both typesof

LVDTs u'ork basedupon the sameprinciplespresentedearlier. The (DC-DC) LVDT is an (ACAC) one with a built rn crrcuitry,rvhichsupportsthe (DC-DC) LVDT using (DC) input that

(DC) output. The maximum(DC) input voltagevariesfiom 6 to 30 V dependingupon

generates

thc type of LVDT (rnanufacturer).

Althoughan [.VDT is an electricaltransformcr,it

What is thc basicinstrurlentation?

requiresAC porverofan amplitudeand fiequencyquite dillerent fiom ordinary po\\'erllnes to

opcrateproperly(typically3 V rn.rsat 2.5 kHz-). Supplyingthis excitationpower lbr an LVDT is

ion, which is also knorvn as LVDT signal

one of sevcral functions of the instrumentat

conditioningcquipment.Otherfirnctionsincludeconvertingthe lou' level (AC) outputof the

LVDT into high level (DC) signalsthat are more convenientto use, decodingdircctional

inlbrmationfi'om 180' output phaseshift as the core o1'anLVDT movesthroughthe null point,

and providingan electricallyadjustableoutputzcro level. Figure 4 showstypical diagram

electronics.

representation

of LVDT signalconditioning

IN Stn u l,t Er.,,teT tot t

AC-ACLI/DT

availablefbr useat NSEL. A

Thereare a numberof pieccsof LVDT instrumentation

rvith LPC-2000of Macro Sensors(Reference1) is providcdin the

discussionof instrumentation

follorvingparagraphs.The user shouldalso be arvareof signal conditionerSCXI-15'10of

NationalInstruments(Refcrence3).

LPC-2000PorverSupplvand SignalConditioner

modules

Figure5a shor'vs

a setof six (6) LPC-2000powersupplyand signalconditioner

mountedin the enclosure(blue box) equippedadditionallyrvith a voltmeter,porversrvitch,

moduleselector,and outputrangeslvitch. Figurc 5b showsthe back of this systemrvith six

and six BNC outputconnectors.Figurc6 shorvsthe singlemodule,

LVDT bendixconnectors

rvhichsupportsgiven AC-AC LVDT. The LPC-2000is a compact,singlc channelAC-operated

o1-mostLVDTs. Operatingat ll0-220 V,

capablcof providingconditioning

signalconditioner

requiredto operatethe positionsensor

provides

all

necessary

circuitry

50-60 Hz, the LPC-2000

and providea high level, reducednoise analogDC output at the rangeof +10 V, which is

suitablelbr leeding analogor digital control indicators,ProgrammableLogic Controllersand

other systemindicatingand control instrumentation.The LPC-2000rnoduleis also capableof

I.

generatinga 4-20 mA loop output. Instructionrnanualfbr LPC-2000is availablein Rel'erence

Operationof the LPC-2000and AC-AC LVDT

I.

Connectthe LPC-2000porversupplyand signalconditioner(blue box) to thc I 10 V, 60 Hz

sourceof electricalpolver. Flip the toggle sr'vitch"POWER" on the po*'er supply (Figure

5a). Wait at least5 minutes(rvarm-uptimc) belbreproceedingto step2.

2.

Turn the "LVDT SELECT" to channelI (Figurc 5a). Srvitchthe "METER RANGE" to 2 V

in Figure7 intothe outletI (Figurc5b) Using

rangc(Figurc5a). Plugin thejumpershctrvn

ir

Automatic

amplitude

control

Fig. 4 LVDT supportelechonicsdiagram.

b)

Analog

output

LVDT

outlet

LPC 2000modulesin bluebox for usewith AC-AC LVDTs:

Fig. 5 Six Macrosensors'

a) Front view, b) Rearview.

7

I

.\

t-

I

I

I

I

I

Fig. 6 A moduleof Macrosensors'LPC 2000

for usewithAC-AC LVDT.

Fig. 7 Jumper.

I

I

Dial gauge

I

Housingof LVDT

I

I

I

Fis 8. Calibrator.

I

I

6

the "Zero"resistor(Figure6) anda smallscrewdriveradjustthe "METER" readingto 0.000

V. This meansthat the amplifier of the channel1 generates0.000V output. Repeatthis

operationfor all channelsto be used.

3 . Switchthe'METER RANGE"to 20 V range(Figure5a). Removethejumper from outlet I

(Figure5b) andplug in the LVDT connectorinstead.Mount the LVDT into the calibrator

(Figure8). Move the housingof LVDT up and down until the zero V (0.00 V) outputis

achieved.This meansthatthe electricalzero(null) of LVDT wasfound. Setthe dial gauge

of the calibratoralsoto zero. Move the housingof LVDT to its full range,e.g. 1 in. Using

(Figure6) until either-10.00V or +10.00V is

smallscrewdriver,

adjustthe"SPAN'resistor

achieved(thesigndependsuponthe directionof motionof the LVDT housing.Takeoutput

voltagereadingsevery10%of the LVDT readings;

e.g.for +1 in. LVDT, 0.1 in. interval

shouldbe used.Takethe readingsgoingin bothpositiveandnegativedirections.

,1

Plot the dataoutputvoltageversusdisplacement

andobtainthe leastsquareequationwhich

couldbe usedduringexperimental

datareduction.

5 . Repeatsteps3 and 4 for eachLVDT to be usedat eachchannel. The blue box supportsa

maximumof six channels.

6. Each blue box has a set of six analogoutputs(Figure 5b), which can be usedfor either

calibrationor datalogging.

DC.DCLVDT

SinceeachDC-DC LVDT has a built-in circuitry,which is an equivalentof LPC-2000,

any DC powersupplycanbe usedfor its operation.An exampleof DC power supplyis shown

in Figure9.

Operationof DC PowerSupplyandDC-DCLVDT

1. Connecta DC powersupplyto the 110V,60 Hz sourceof electricalpower. Turn it on

(Figure9) andwait at least30 minutes(warm-uptime)beforeproceedingto step2.

2. Adjust the outputDC voltage(excitationvoltage)from the power supplyto the value

usuallyit is between6 V and 30 V. Connectthe

specifiedby the LVDT manufacturer;

outputfrom DC powersupplyto the fansition box shownin Figure 10. Make surethat the

polarityis conect;minusgoesto minusandplusgoesto plus. If the polarityis reversed,

the

outputfrom LVDT will be closeto zero.

3. Connectthe LVDT to oneof six channelsof thetransitionbox (Figure10a). Also connecta

voltmeterto thetransitionbox (Figure10b). Mountthe LVDT into the calibrator(Figure8).

Move the housingof LVDT up anddownuntil the zeroV (0.00V) outputis achieved.Set

the dial gaugeof the calibratoralsoto zero. Apply the full rangeof displacementto the

LVDT. Adjust the excitationvoltagein sucha way that 10 V output from the LVDT is

achieved.Move the LVDT backto its zeropositionandapplythe full rangein the opposite

direction. The outputvoltageshouldbe equalor lessthan 10 V. If it is higherthan 10 V,

reducethe excitationvoltagein sucha way thatoutputof 10V is achieved.Move the

To ffansition box

Fig. 9 DC powersupply.

a)

b)

To power

supplyor

voltmeter

Analog

output

Fig. 10 Transitionbox: a) Frontview, b) Rearview.

l0

LVDT back to its zero position. Calibratethe LVDT by applying an interval of

displacement

equalto 10%of the fulI rangeof LVDT; e.g.for+1.0 in. LVDT, the intervalis

equalto 0.1in.

4. Plot the calibrationdata in the displacement-voltage

coordinates.Using the leastsquare

linearregressionmethod,determinethe equation6 : f(Uou, where 6 is the displacement

(in.) andUe'r is the outputvoltage(V) from the LVDT. An exampleof the calibrationline

is shownin Fieure11 wherer is thecorrelationcoefficient.

+ (0_70998)Uod,

6 r 0.0091283

r! 1.000

3n

,2.

5.4

3a.1

012

3

4

5

OutputVoltags,UodM

Fig. 11 An exampleof calibrationdatafor +/- 3.0 in. DC-DC LVDT.

INsrer-lertoN

whenmountingLVDTs?

Whatthingsshouldbe considered

Mountingfixtures,core extensionrods,and hardwarelocatedwithin an inch of the LVDT

shouldbe madeof nonferrousmaterialsthat arepoor electricalconductors.This is to avoid

by changingits magneticfield or by enablingeddy

compromisingLVDT performance

stainless

currentsthat work againstthis magneticfield. Prefenedmaterialsarenonmagnetic

plastics.Nonmagneticmaterialssuchasaluminum,brassandcopper

steelsandengineering

may alsobe usedprovidedthe massis smallandthe materialis split axially to impedeeddy

currentsconcentricto the LVDT.

Thebody ofthe L\IDT shouldbe securelyfastenedby clampingthe housingin a split block

or similarfixture. NSEL hassplit blocksmadeof a compositematerialcalledKevlor (Figure

12a). Thesenonmagnetic

blockscanbe machinedeasilyfor a particulartestapplicationand

for differentdiametersof LVDT housing.Figure12bshowsan LVDT insertedinto a Kevlor

block. Clampingthe body of the LVDT nearits electricalcenterwill minimize zero shift

with temnerafure.

ll

mnge

The core shouldbe positionedto allow ftee movementthroughthe entiremeasurement

of the LVDT. With proper alignment, the core will not contact the bore, resulting in

frictionlessoperation. If the contactis significant,frictional wear will result in non-linearity

anddegradationin sensitivity.

Fig. l2a Kevlor split block.

Fig. 12b LVDT insertedinto a Kevlor split block.

LVDTs beingusedto determinedisplacementsof a model frame,with the outer casingof

each LVDT attachedto an auxiliary supporting frame and the movable cores attachedin a

springJoadedfashionto the model, are shownin Figure l3a. The LVDT can alsobe adoptedto

act as a strain gaugeto monitor strainsover a moderateor extendedgagelength as shown in

Figure 13b. Otherapplicationsof LVDTs areshownin Reference2.

The range and number of LVDTs available at NSEL can be found at our website:

htto://cee.ce.uiuc.edu/nsel/Iacility/lvdt.htm.

t2

andstrains:a) LVDTs

Fig. 13 Useof LVDTs in measuringdisplacements

for

for deflectionmeasurements,

b) LVDTs

strainmeasurements.

RT,FERENCES

Ref. 1

InstructionManual. Line PorverOperatedLVDT Signal Conditioner,Model LPC2000(included).

Ref.2

Handbookof TransducerDesign,Engineerfurg

and Application,Trals-Tek lnc (partly

included).

Rel 3

SCXI-1540UserManual,8-ChannelLVDT SignalConditioner,NationalInstruments,

Mach 2000Edition.

Ref.4

Harris,H. G. and Sabnis,G. M. StructuralModelingand ExperimentalTechniques,

SecondEdition,1999.p. 348-352.

Ref.5

Herceg,E. E. Handbook of Measurementand Confol, publishedby Schaevitz

Engineering,1972.

I

13

-J

n"f. 6

Lion, K. S. Instrumentationin Scientific Research,published by McGraw-Hill Book

Company,Inc., 1959.

, I

{

Ref. 7

Ramsay,D. C. Principlesof EngineeringInstrumentation,publishedby HalstedPress,

1996.

I

Ref. 8

http://www.macrosensors.com

Ref. t

http://www.sentechlvdt.com

JI

t

-t

{

I

i

I

{

I

i

J

II

,i

I

I

I

I

I

I

I

.,

l

t

I

I

I

I

.l

I

Ref. 10 http://www.transtekinc.com

J

I

4

,l

,i

I

I

t.

i

II

I

I

i

I

i

I

I

,l

I

I

I

i

I

I

I

.

Reference1

ln,structionManual

Line Power

Operated

LVDT

$ignal Conditioner

ModelLPC-2OOO

U.S. Route t3O North

Pennsauken,NJ O81{|l.i541

Phone: 85G662-80OO

FAX: 85e3'l?-'l005

DESGN|PI|OX

capableofoperatingrnoslLVDTSandRVOTS.

TheLPC2000is a compactsinglechannelAoline powe.edsignalconditioner

Operating

from115V or 220VAC, 50.60Hz,an LPC2000providesall circuitryrequiredto operatean LVDTposilionsensor

andprovidea highlevel,lo\,vnoiseanalogDCoutputsuihblefor feedinganalogor digitalindicators,PLCS,andothersystem

indicatingandconuolinsfumentration

or a 4-20nA 3+Ji.ecunentloopoutputTheLPg2000featuresuser€eleclable

ate madevia

ftequencyandgainto functionwittlsensorshavingwidelydifferentsensitivitjes.Conneclions

excitiation

recessedscrewterminalsat thetoDandbottomof thecase whichmountson DINI or DIN3 rail.

SPEiCtF|GAI|OXS

...1| 5 or 220V AC,50-60l|z' 25 VA

PovrerInputVoltage.....

V ms (Nom.)

LVDTExcitation

Vo|tage...................................3

kHz,5 kHzor 10klts

LVDTExcitation

Frequency.................3

Ohms(min.)

LVDTPdmary

1mpedance........,.....................200

Output,

VoltageMode..................................t10V

DC@ 5 nA

Output,Curent

Mode.....,....,4-20

mAsourcing,

300ohmsmax

Frequency

Response..,

3 db at250Fts

<10mVnrs

Output

Ohms

Outputlmpedance,......

.........<10

FSO

Non1inearity..................

....10.01"/o

Temp.Range.,..,.....0"F

to +70'C)

Operating

!c +160"FG18'C

FSOfC)

Temp.Coeff.of Sens...-.......0.01yo

FSOrF(0.018%

.ZeroandSDan

Conbo1s..........,...,........

(200grams)

ounces

Weight........................,..........................7

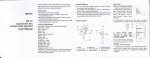

MOUNTING

orDlN3,

TheLPC2000is designed

to mounton theDINrailmountingsysternincluding

DIN1,32mmX 15mmasymettical,

35mmX 7.5mmor 15mmsymmetical,r.lilsas illustratedbelow.

DIN I Mounting

l5mm

n

DIN 3 Mounting

2

LVDT

Secondaries

Yellow (E)

Primary

Red (A)

Mu.l b. cdn.cLd

tog.th.r, but

Hhl

-"""'

LJUttl

Blue(B)

t.?_t_ |

ll

Brown(F) Black(D)

r

-l------

rflo

Flt a

EO

@o

Top

Et{ ELo

rc,

Ltne

E

Llno

AC Lln€

Ground.

AC Power lnput

Wiring Note: The wire colorsand/orlettersshownin the connectiondiagramapplyonly to Macro

Sensors'standardAC LVDTSwith 6 leadwiresor 6-pinconnectors.For LVDTSwith otherterminationssuch as BB seriesgagingprobesor SQ seriesheavyduty LVDTS,or for extensioncablesused

with LVDTS,consultthe data sheetaccompanying

the LVOTor cablefor the correctcolorcodesor

terminalconnections.Connectthe LVDT'Sprimaryand secondariesto the signalconditioneraccording io the wiringdiagram,observingthe magneticpolaritydotson the LVDTwindingschematic.

3

GONNECTIONS

screwclampterminalsthatwillaccept

All wireconneclions

to the LPG2000a.ethroughindusfystandardrec€s.sed

wiresizesfrom#28AWG

to # 12AwG,eithersolidor stranded.

Wiresshouldbestipped5/16'(8mm)whichwill

providethe properlengthof conductor

withoutexposinganybarewire. Linepowerinputwiring shouldutilizea

minimum

sizeof #18AWG.Bestlretg de+neroizepowerlinepriorto makinopowerconnections.

INTERNAL ACGESS

It maybe necessary

to gainaccessto lhe insdeof tle LPG2000to adjustexcitationfrequencyand/orgainjumpers.

De.ene.oizelinepower.Usinga knifeblade,smallscrevvdriver

or similar

tool,genuypryoffthecoverat points

indicated

in figurebeb/v.

WARNING !

Danqerousvolhqes are presentinsideeneruizedunit I Be sure to decnemize unit prior

to rcmovalofcover!

-

It-

ffi

|.-

,flr,-*l

4

EXCITATION FREOUENGYSELEGTION

The LPC2000hasthreeuser€electable

LVDTexcitationftequencies.Thedesi.edlrequencyis normallysetb matchthe

specifications

and/orrecommended

operatjngfrequencyof lhe LVDTbeingused. As shippedfromthefaclory,theunitis set

for 3 kHz excjtationfrequencywhichis commonto manyLVDTS.Frequencyischangedbyjumpers(shortingba|s)on Sl, S2

and53. (seeFrgure1).As supplied,a jumperis positioned

adossSl as shownin Figure1. To obtain5 kHz,rnovethe

jumperfiomSl to S2. To obtain10kHz,movethejumperfromSl io 53. WARNINGI !q!!ags!!C lggeldzCgl4lC!

coveris removed.Oanoerous

voltaoesareoresentinsideeneroized

unitI

OUTPUT GAIN SELECTION

The LPC2000 can operatewith LVDTShaving a widerangeof sensitivities.Coa6egainselectionis providedto permit

operationwith most LVDTS. To set coarse gain,

oerformino

thefollowino

calculation:

Sensitivity

inVolts/.001"X Excitation

VoltageX FullStrokein thousandths

of an inch= FullScaleOutput(VAC rms)

Examplel: 4.050" Sfoke LVDT

Sensitivity:

X 3V rmsX 50 (12 rangein .001")= 0.975VACrmsFullSc€leLVDTOutput

0.0065V/.001"

Example2: tl.000" StrokeLVDT

Sensitiviv:

0.00065V/.001"

X 3V rmsX 1000(1/2rangein .001")= 1.95VACrmsFullScaleLVDTOutput

Gainnay be adjustedby placingjumpersS4,35, 56, andS7 (shortingbars)in positionsshownin thetablebelow.Placing

jumpersasinsbudedwillyielda t10 V OCoutputat fullscaleLVDTdisplacemenl

GAINSELECTION

TABLE

s4

s5

s5

s7

0 - 0.3v

Open

Open

Open

Open

u.31V- 0.bv

Open

Jumper

Open

Open

0.6'1V- 2.5V

Open

Jrmper

Open

Jumpel

Jumper

Open

Jumper

Open

.VDT Full Scale

)utput AC Volts

!tndicates.tumler

positions

asshipped

fromfac1ory

5

to

A requirement

mayexistwheremultipleLPG2000S

areto b€ usedandwhereunjlsorwiringwillbe locatedin closeproximity

theoscillators

of multipleunitsto preventcrossblk,beating,andinternodulation

eaci other.TheLPC-2000cansynchronize

betweenunib. To synchronize

the oscillators,

connecitogetherterminal5 on all unitsandconnectbgetherterminal10onallunits.

Theseconnections

are j!3gdi!9!..1ptheconnedionsshownon page3. Oneunitshouldbe designatedasthe"Mastefandthe

'Slaves'.

withthe insttuctions

balanceof the unitsdesignatedas

The'Mastef unifsexciiationfrequencymustbe sd in acco{dance

givenintheparagraph

"Excitation

Frequency

entitled

Seledion'.

Onthe'Masteiunit,movejumperlrom58 to 59. 'Slave"units

(shortng

ffom51,52, 53 and59.

musthaveajump€r(shorting

bar)on 58 andalljumpers

bars)mustberemoved

LPG-zO0 Slave l:l

Additional Connections For IPC-2000 Mult'rchannel

eMaster/Slave" Confi guration

GALIBRATION PROCEDURE(Voltage

Output)

jumperbetween

7 andI

Tocalibrate,

remove

LVDTsecondary

wire,usuallyRedo. (A)fromterminal

9. Inserttemporary

te.minals

(thisjumper

power

Adjusttheze.o

wjllberemoved

afierZeroadjustrnent).

ApplyAC

tgunitand

allowa 15 minute

wannup.

jumperfrom

controluntilan outputof 0 V DCis obtainedb€tveenterminals4 and5. De-energize

unitandremovetemporary

between

teminals7 and9. Re-connect

secondarywire

Redor (A)to terminal9,Applypowerto unitandmoveLVDTcoreor

pointfromwhich

thereference

bodyunlilanoutputof 0V DCis obtained.

Thisposition

isthetruenullofthesensorand

subseouent

oosition

measurements

aremade.

makethisadjustrnent

as closeas

NOTElf rnechanical

adjustment

of thecorcor LVDTbodyis difiicultor impossible,

possibleandthenadjusttheZerocontrolto obtain0 V OCoutput.lt is importantthatthe LVDTbewithin5oloof its kue nullposition

is withintheLVOTS

ratedlinearrange.Offsetsof morethan5%mayresultin non-linearresultsat

to ensurethatfull displacement

or neaafullscaledisglacem€nt.

Movethe LVDTcoreto its full scaledisplacement

andadjustthe Spancontrolto obiaina readingof 10V DC. Outputsof lessthan

bySpan

10V DCmaybeobtained

theSpancontol(e.9.5VDC).lfdesi.edfullscaleoutputcannotbeobtiained

byadjusljng

tableonpage

control

adjustment,

resetgainjumpers(shorting

bars)to nexthigheror lowersettingasshownin'GAINSELECTION"

to resetgainjumpers.Ecsg!el9-de=!!e!g!29-q!!

5 andthenreadjustSpanconkolto obtaindesiredoutput.lf it is necessary

Drioato removinocover.

Unitis nowreadyfor normaloperation.

GALIBRATION FOR 10O% ZERO OFFSET (Voltageoutput)

100%zerooflsetallowsthe userto obiaina unipolaroutputoverthefullrangeof theLVDT.

PROCEDURE"

section

fortullscaleuse,butadjusttheSpancontrolfor

inthe'CALIBRATION

Followtheinsfudionsasdescdbed

andadjusttheZerocontrol

halfthedesired

fullscaleoutput(e.g.5 V DC).MovetheLVDTcoreto'minLE'tullscaledisplacement

fordesired

tullscaleoutput.

andadjusttheSpancontrol

to obtainzerooutput.MovetheLVDTcoreto'plus"tullscaledisplacement

Repeat

thisprocedure

to ensurepropercalibration.

Unitis nowreadyfor unipolar

operation.

6

GALIBRAT]ON FOR 4-2OmA CURRENT LOOP OUTPUT

To calibEteunitfor cunentoutput,makesurethatcunentloopconnedions

aremadebetweenTenninals5 and6. Remove

jumperb€tweenterminals7 andI (thisjumperwill

LVDTsecondary

wire,usuallyRed(A)fromTerminal9. Insedtemporary

betemoved

afrerzercadjusiment).

ApplyACpowerlounitandallowa 15 minutewarrrup.Adjustzero

cgntroluntila

jumpertrom

readingof12mAis oblained.De-energze

unitandremove

between

Terminals

7 and9. Rg-connect

secondary

wireRed(A)to Terminal9. Applypowerto unit. Move LVDTcoreor bodyuntil12mAoutputis obtained.Thispositionis the

tue nullposition

of thesensorandthepointfromwhichsubsequent

measurements

aremade.

NOTE:lf mechanicaladjustrnent

of thecoreor LVDTbodyis difficultor impossible,

makethisadjustment

as close

possible

as

andthenadjusttheZerocontrolto obtain12 mAoutput. lt is importantthatthe LVDTbewithin5%of itstruenull

or zeropositionto insurethattulldisplacement

is withinthe LVDTSratedlinearrange.Offsetrs

of morethan5%mayresultin

non-linear

results

at or nearthefullscaledisolacement.

MovetheLVDTcoreto its"dJs' fullscaledisplacement

andadjustthe

Spancontroltoobtaina reading

of20 rnA Retum

the

coreto "minus"full sc€le positionandadjusttheZerocontrolto obtaina readingof 4 mA.l\4ovethe coreto the'plus"fullscale

positionandadjustthe Spancontrol!o obtaina 20 mAreading.Repeataboveprocedure

to ensureproperouFutat both

extremesof thecoretravel.

Unitis nowreadyfor normalcunentoutputopel-ation.

Directional Sense

Ifthe slopeof theanalogoutputvoltageor cu.rentis thereverseof the desi.edslopg,i.e.,if the ouFutvollageor cunentincreasesor deqeasesopposrteto the desireddirectionof coremotjon,revecethe LVDTconnections

to terminals7 andL

1.37

|

OUTLINE

Fom *io4.il R.v. Gltl @Hdad A S.na.vh2

lo€hnolotlG,

In.. 201,1. BacF S.nsoF ls t

rogl3t ..d tEd. o.ri of Howard A. Scha.vltz

-i

-i

I

I

J

I

I

I

.J

I

I

I

-J

I

I

)

i

I

I

)

I

It

I

.J

I

I

I

II

t

j

I

-)

I

I

I

2

Reference

l:'

- LVDT- LinearVariableDifferentialTransformer

i'

Tbchnology

Trans-Tekdesignsand manufacturesa broad line of linear

transducers

usingLVDT tecbrology. An LVDT, or

displacemenl

Linear Variable Differential Transformer,is an inductive device

containing primary and secondarycoaxial wound coils and a

fenomagneticcore. Excitingthe primarycoil with an AC voltage

generatesanelecfomagneticfield. The corelinks theelectromagnetic

coils,inducinga voltagein

freld ofthe primarycoil to thesecondary

each. The secondarycoils are q?ically wired in seriesopposition,

producingAC voltages180 degreesout of phasewith eachother.

The magnitudeof the voltagein eachsecondarydependson the

oositionofthe corerelativeto the coils.

NON-CONTACTING

CORE

II,,I

FINITE RESOLUTIOI.i

By design,the coredoesnot makecontactwith the imer diameter As an analogdevice,theoreticalresolutioncan be definedas

of the coils with proper aligffnent. This very important design infinite. Resolutionis the smallestincrementof movement

detail providesfrictionlessmovementof the corethroughthe detectable

betweenthe coreandcoils.

inner bore of the coils creatinginfinite mechanicallife.

Applicationsdemandinghigh reliability and low failure rates

benefitfiom this basicdesignfeatule.

NULL POSITION

When the physical center ofthe core is in line

with the electrical center of the coils. the

voltage induced in each secondaryis equal in

magnitude, but opposite in phase. When

summed, the secondaryvoltages cancel each

other, resulting in zero output volts. This is

the null position ofthe LVDT.

Primary Excitation

VRMS

,CEtl:

TE@W

This inherent symmetry in the LVDT

constructionallows for a highly repeatablenull

position. Many LVDT applications revolve

around this one feature, especially in closedlooD control svstems.

Pdmary Excitalion

VRMS

tG@,

EIE@:

}\{t*"

;+7^v^-.,-*,

:

Secondary 1

Secondary 2

p#,,,**

JaM.**,

Secondary1

C 0'R E ;il S1.ri: i"{: i\T

An LVDT is designedto have

symmetric measurement

rangeson eachsideofnull. As

the coremovesto onesideof

the null position, the

magnitudeof one secondary

b e c o m e sg r e a t e rt h a n t h e

other- Combining the two

secondaryvoltagesresultsin

anoutputvoltageproportional

to tbe core's distancefrom

null. Thephaseofthis voltage

indicates

whichsideofnullthe

is

localed.

core

Secondary

2

Pdmary Excitation

VRMS

,W@FEW

: EE@@Eg

:

frffi.,-".,$o-.,*o

Secondary 1

Secondary2

i

-r

t

,!

,a

i

:!

'7

iii:- D C i-r,,i3T^ i l\jT: G H,i L * IS r.:4,:_it I irrtjt'ii I ti I Ljfi

Signalconditioningis animportantconsiderationwhendesigning

anLVDT into an application.ConvertingtheAC outputvoltage

of the secondaries

into a usableDC outputvoltagerequiresa

andlow passfiltering.Designofthe circuitrymust

demodulator

take into accountfrequencyresponseand electricalnoise

considerations.For convenience

and easeof use,Trans-Tek

a completeline of DC-DCLVDTs, alsoknownas

manufactures

DCDTs,containingan integraloscillator/demodulator.

CUTPUTVS.DiSPLACEI./lENT

VDCOutsul

Discretecomponentsmakeup the integralsignalconditioner.

The oscillatorconvertstheDC voltageinputto ahigh frequency

AC voltage,poweringtheprimarycoil. A passivedemodulator

circuit reclifiesthe AC voltageoutputfrom the secondaries

and

differencesthe resultingsignalbeforefilteringwith a low pass

RC filter. The magnitudeandpolarity ofthe DC output voltage

are dependanton the positionof the core relativeto the null

position.

DC L\_/l: B!-CCK ]:.irc=ri\i

s

t;:

jl.:

{

Trans-Tek'sDC LVDTs are inputpolarityprotected,meaning

that polarity of the input leadsmust be observedfor proper

by polarityreversal.

operation,but theunit will not be damaged

TheDC voltageinputcanrangefrom 6 to 30 VDC, andmustbe

regulatedfor bestaccuracy.Themagnitudeofthe outputvoltage

is controlledby theinputvoltage.TheseDC LVDTs alsofeature

input andoutputcircuitsisolatedboth from eachotherandthe

which canbe usedin a

coil housing.The resultis a transducer

floating or groundretum system.

T

.i

i.v DT ir.,;ic

li \iTii\iG c ut jiSi_i!.iE5

Mountingfixtures,coreextensionrods,andhardwarewhich are

locatedwithin an inch of the transducershouldbe made of

nonferrous

materialsthatarealsopoorelectricalconductors.

This

is to avoid compromisingtransducerperformancedirectly by

changingtheshapeofthe unit's magneticfieldsor indirectlyby

enablingeddycurrentswhich work againstthe unit's magnetic

stainlesssteels

fields. Prefenedmaterialsincludenonmagnetic

and engineeringplastics. Nonmagneticmaterialssuch as

aluminum,brassand coppermay be usedprovidedthe massis

small and the material,is split axially to impedeeddy cunents

concentricto the LVDT. Iron and masneticsteelsshouldbe

avoided.

Thebodyofthe LVDT shouldbesecurelyfastenedby clamping

the housingin a split block or similarfixture. The useof set

screwsshould be avoided,as this may damagethe LVDT.

Clampingthebodynearthe electricalcenter,E., will minimize

zero shift with temperatue.The coreshouldbe positionedto

allow fiee movementthroughthe LVDT'S entiremeasurement

range.With properalignment,thecorewill not contactthebore,

resultingin frictionlessoperation.Contactbetweenthecoreand

the bore will not immediatelyaffecttransducerperformance,

however,significantfrictionalwearwill resultin a degradation

in sensitivitvandnonlinearifi.

:i

01F

LVDT

Applications

KnifeInlelligence

lor Garment

Machine

Automotive

PartsAssembly

Bottle

Height

Inspection

ooooo

Actuatorfeedbackis criticalin controllino

papercoatingthickness.

Heightis measuredby the positionof a verticalrod

comingin contactwiththe mouthof the bottle.

Automolive

Suspension

System

Durabilityof structuralcomponentsare

conlinuously

checkedunderconditions

of stress.

Measuresfluid levelthrough{loatpositioninsidea

valve, providingstablevehicleride performance.

Roller

Thickness

Measurement

Robolics

Joystick

Conlrol

1

.''

tn

achievedesiredmaterialthickness.

roboticarm followsoperatofsarm movement.

Weighing

Systems

Fluiddensityis determinedby measuringlhe

positionof a floatsuspended

in a knownflux liquid.

Hydraulic

Servovalves

(Using

Vented

LVDT)

Hvdraulic

---"'-..

Fiuid

LVDT

withVented

Housing

Knowingthe deflectionof a springandthe spring

constantleadsto the calculationof weiohtor force.

Hydraulic

Servovalves

(Using

lsolation

Tube)

Pressurized

lsolalion

Tube

lmmersedin compatiblehydraulicfluid,a venled

pressurethroughout

housingequalizes

the LVDT.

An isolationtube housesthe movingcoreand

proteclsthe LVDTfromthe highpressure

fluid.