Download - Cap-XX

Transcript

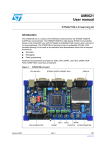

www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 cap-XX Compact Flash™ Extender and Supercapacitor Evaluation Board Part No. APPEB1004 User’s Manual Revision 1.0 March, 2003 Evaluation Board Features • • • • • CF Extender Supercapacitor (two form factors) Adjustable current limit circuit with Supercapacitor charge enable 3.3V and 5V input LEDs Supercapacitor voltage comparator with adjustable threshold, adjustable hysteresis and Power Good LED • Card Detect switches to simulate card removal and insertion • Sub-circuits can be disconnected to reduce the load • Test points, jumpers and I/O connectors Typical Supercapacitor Applications • • • • • • • Compact Flash PC card PDA Smartphone GPRS Handheld Equipment Load Leveling © cap-XX Pty Ltd, 2003 1 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 Contents 1.0 Introduction 3 2.0 Input Voltage 3 2.1 Charge Time 3 3.0 Current Limit 4 4.0 Enable 4 5.0 Power Good 4 6.0 Adjusting the Circuit 5 6.1 Adjusting the Current Limit with “Current Limit” - R2 6.2 Adjusting Hysterisis Width with “PGOOD Feedback” - R23 6.3 Adjusting the High Threshold with “PGOOD Reference” - R15 6.4 Replacing the Potentiometers with Fixed Resistors 6.5 Limits of Adjustment 6 6 7 7 8 Connecting the Evaluation Board 8 7.1 VCC Modes 7.2 Current Measurement 7.3 Card Detect 7.4 Voltage Select 9 10 11 11 Disconnecting Circuits for Reduced Load 11 7.0 8.0 Appendix Schematic PCB Top Overlay PCB Top Layer PCB 2nd Layer PCB 3rd Layer PCB Bottom Layer © cap-XX Pty Ltd, 2003 12 12 13 14 15 16 17 2 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 1.0 Introduction This User’s Manual is for the cap-XX Compact Flash™ (CF) Extender and Supercapacitor Evaluation Board (Part No. APPEB1004). This board was designed for the evaluation of a supercapacitor in a CF Card. The application of supercapacitors is limited only by the user’s imagination. Typical examples are CF, PC Card, PDA, Smartphone, GPRS and other handheld equipment. The Evaluation Board is a CF Extender with a supercapacitor, a current limit circuit and other features. An excellent source for information on Supercapacitors and free downloads are available on the cap-XX website at www.cap-xx.com. In the following description of operation it may be helpful to refer to the Evaluation Board Schematic in the Appendix. 2.0 Input Voltage The supercapacitors for the Evaluation Board are rated at 4.5V and therefore it is not recommended that the input voltage (VCC) be greater than 4.5V. If VCC is 5V then the Equivalent Series Resistance (ESR) rise rate of the supercapacitor is increased and the lifetime will be reduced. A red LED is included to indicate that VCC is too high and it starts to glow when VCC is approximately 4.2V. The red LED is labeled on the Evaluation Board as “5 Volts”. If VCC is 5V then the voltage can be dropped to < 4.5V by removing a jumper which introduces a series diode in the voltage supply lines on the Evaluation Board (see section 7.0). A yellow LED is included to indicate when VCC is 3.3V or greater. It is labeled on the Evaluation Board as “3.3 Volts”. If VCC is disconnected (or if the Evaluation Board is removed from the host) and there is still charge on the supercapacitor then current will flow through the body diode of M1 and through the yellow LED (also through the red LED if the supercapacitor is greater than ~ 4.2V). The intensity of the yellow LED then gives an indication of the voltage remaining on the supercapacitor. If, however, the series diode has been included to reduce the 5V rail to 4.5V then the LEDs will not be ON when VCC is disconnected. 2.1 Charge Time A fully discharged supercapacitor will be charged to VCC after a certain time (tc). This time will depend on the current limit (IL), VCC and the capacitance (C). The equation is tc = © cap-XX Pty Ltd, 2003 CVCC IL (1) 3 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 3.0 Current Limit Circuits that employ large capacitors generally need a current limiting circuit to alleviate the current in-rush problem. The CF specification states that the peak current is 500mA from either the 3.3V or 5V rail. The tolerance on the 3.3V rail is ± 5% and the tolerance on the 5V rail is ± 10%. Therefore the peak power from the 3.3V rail is 1.65W ± 5% and the 5V rail is 2.5W ± 10%. The Evaluation Board has an adjustable current limit circuit. The current limit can be adjusted from 0A to ~ 4.5A by using the potentiometer R2. It is labeled on the Evaluation Board as “Current Limit”. Turning the potentiometer clockwise will increase the current limit. The MOSFET (M1) and Sense Resistor (R1) can withstand up to 4.5A whilst the supercapacitor is being charged. They cannot however withstand the 4.5A into a short circuit indefinitely. There is no short circuit protection. The MOSFET (M1) has a maximum continuous power dissipation of 2.5W. Therefore any continuous load resistance (RL) has a minimum value as given by equation 2. VCC I L − 2.5 I 2L RL = 0 RL ≥ [VCC I L > 2.5] (2) [VCC I L ≤ 2.5] RL also has a minimum power rating according to equation 3. PR L > I 2L R L PR L 2 VCC > RL [input current = IL] (3) [input current < IL] 4.0 Enable The current limit circuit has an enable feature. Enable is an active low signal and the two pin jumper is labeled on the Evaluation Board as “J_ENABLE”. It is an input signal to the Evaluation Board and it can be jumpered to ground, to be permanently enabled, or it can be externally driven by an open collector or drain. When “J_ENABLE” is externally driven it allows the supercapacitor to be charged only when the User’s Card is ready. Pin 2 of “J_ENABLE” is the control input and Pin 1 is permanently connected to ground. 5.0 Power Good The Power Good circuit (PGOOD) is included to indicate when the supercapacitor is charged to the appropriate level. The voltage on the supercapacitor is compared to a reference using a comparator with adjustable thresholds and hysteresis. The thresholds need to be adjustable on an Evaluation Board because different applications will require different load voltages. The hysteresis also needs to be adjustable because a step in load current will cause a step voltage on the supercapacitor because of the supercapacitor’s Equivalent Series Resistance (ESR). © cap-XX Pty Ltd, 2003 4 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 Since this step voltage (part of the ripple) is a normal occurrence, it would not be desirable for this to indicate that the supercapacitor is undercharged. Power Good LED On LED Off VTL VW Vcc VTH Figure 1 Power Good Hysteresis As in Figure 1, the high threshold (VTH) is the voltage at which the supercapacitor’s unloaded voltage becomes acceptable. The hysteresis (VW) is the voltage that when subtracted from the high threshold gives the low threshold (VTL). It indicates that the supercapacitor is undercharged. VTH is set by the factory at 3.2V and VW is set at 0.3V, therefore VTL is 2.9V. PGOOD has a header labeled on the Evaluation Board as “H_PGOOD”. It is an active high output signal that can be used to signal an external circuit that the supercapacitor is fully charged. A green LED is also included to indicate this condition. It is labeled on the Evaluation Board as “Power Good”. 6.0 Adjusting the Circuit Equipment needed: Adjustable power supply, multi-meter and various power resistors Warning: Be careful not to exceed the supercapacitor rated voltage (4.5V) or the maximum continuous power rating for M1 (2.5W) (a) Ensure the following jumpers are fitted; “J_RED&YLW”, “J_GREEN”, “J_PGOOD”, “J_ENABLE”, “J_VCC13_IN” (pins 3 and 4), “J_VCC38_IN” (pins 3 and 4) and “J_5V”. Remove jumpers on “J_VCC13_OUT” and “J_VCC38_OUT”. Pin 1 is marked with “∇”. (b) Turn “Current Limit” - R2 fully anti-clockwise (no current). Set the power supply voltage to say 3.3VDC. Ensure that the power supply can supply the desired current. Connect its negative lead to J_GND1 or J_GND2. Connect the positive lead to pin 1 of “J_VCC13_IN”. (c) Set the power supply output voltage to a value < 4.5V. 6.1 Adjusting the Current Limit with “Current Limit” - R2 Warning: the maximum average power rating for M1 is 2.5W (see section 3.0) (a) Connect a load resistor to “CON_CAPXX” (RL) that draws just over the desired current limit from the CF host (typically 500mA). Note the power © cap-XX Pty Ltd, 2003 5 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 rating of the resistor is according to equation 3 and RL has a minimum value according to equation 2. For example, if the supply voltage is 3.3V and the desired current limit is 500mA then an RL < 6.6Ω would draw more than 500mA. RL can then be chosen to be the next standard value < 6.6Ω, ie 5.7Ω. From equation 3, the power rating of the 5.7Ω resistor would have to be > 1.43W. In this particular example, and according to equation 2, RL can also be a short circuit as this would not overload M1. (b) Place an ammeter in series with the power supply. Turn on the power supply and adjust “Current Limit” - R2 slowly clockwise until the desired current limit is reached. Warning: Do not increase the current limit above that used in equations 2 and 3 for any longer than a few seconds otherwise M1 or RL may be destroyed. (c) Remove RL, turn off the power supply. 6.2 Adjusting Hysteresis Width with “PGOOD Feedback” - R23 NOTE: VW is adjusted before VTH because the VTH adjustment is affected by VW. Therefore if adjustments are made in this section then section 6.3 should be checked. (a) If the CF card is to be driven from the 5V rail, then remove the jumper across “J_5V”, otherwise, if the PC Card is to be driven from the 3.3V rail, then fit the jumper across “J_5V”. (b) Connect a load power resistor (RL) of around 10Ω-47Ω from “VCC_OUT” to “GND_OUT” on “CON_CAPXX”. This ensures that the supercapacitor voltage will change in reasonable time when the power supply voltage is changed. Note the power rating of RL has to be a minimum value according to equation 3. (c) Turn the “PGOOD Reference” - R15 to around mid position (about 11 turns from either limit). (d) Decide the high threshold voltage VTH , the low threshold voltage VTL and the hysteresis voltage width VW (Vw = VTH - VTL). VTL has to be greater than the minimum voltage required by the Pulsed Load. VW has to be greater than the expected voltage droop due to the ESR and capacitor discharge etc. (e) The LED labeled “3.3 Volts” should now be ON and the LED labeled “Power Good” should also be ON. If “Power Good” is not ON, then turn “PGOOD Reference” - R15 anticlockwise slowly until the “Power Good” LED is ON. © cap-XX Pty Ltd, 2003 6 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 (f) Connect a voltmeter across the supercapacitor, which is also across RL and “CON_CAPXX” ( VR L ). Slowly reduce the power supply voltage and note VR L when the “Power Good” LED turns OFF. Slowly increase the power supply voltage and note VR L when the “Power Good” LED turns ON. The difference between the two readings is the hysteresis voltage width Vw. (g) Adjust “PGOOD Feedback” - R23 (anti-clockwise increases Vw) and repeat (e)&(f) until the desired hysteresis width is achieved. 6.3 Adjusting the High Threshold with “PGOOD Reference” - R15 (a) Turn “PGOOD Reference” - R15 fully clockwise and then reduce the power supply voltage until the “Power Good” LED is OFF. (b) Adjust the power supply voltage so VR L equals the desired VTH. Turn “PGOOD Reference” - R15 slowly anti-clockwise until the “Power Good” LED turns ON. (c) Check that the “Power Good” LED turns ON and OFF at the desired levels. This can be done by varying the power supply voltage in both directions so that VR L is less than VTL and then greater than VTH. (d) Remove RL. 6.4 Replacing the Potentiometers with Fixed Resistors The potentiometers on the Evaluation Board are included to provide flexibility in evaluating many different applications. In a final design for production the resistance of the potentiometers would have been decided and therefore they can be replaced with fixed resistors. This section includes the equations that can be used to theoretically determine the value of these resistors. The value of these resistors can also be found practically by measuring the resistance of the potentiometers out of circuit once the circuit has been successfully adjusted as above. R 22 + R 23 = 55k VW (4) R15 + R16 = 4k 7VTH 5 + VW − VTH (5) R2 = © cap-XX Pty Ltd, 2003 22k 56 −1 IL (6) 7 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 6.5 Limits of Adjustment From the schematic in the Appendix it can be seen that; R22=47kΩ R23=500kΩ potentiometer R15=50kΩ potentiometer R16=3k9Ω R2= 2kΩ potentiometer From equation 4; From equation 5; From equation 6; 0.1V ≤ VW ≤ 1.2V 2.3V ≤ VTH ≤ 4.7 V (VW=0.1V) 2.4V ≤ VTH ≤ 4.9V (VW=0.3V) 2.8V ≤ VTH ≤ 5.7 V (VW=1.2V) 0A ≤ I L ≤ 4.7 A If these limits do not suit the application then resistors can be replaced on the Evaluation Board according to equations 4,5 and 6. 7.0 Connecting the Evaluation Board The evaluation board is inserted into the Host and the CF Card under test is inserted into the Evaluation Board, as shown in figure 2. The supercapacitor terminals are joined to the connector labeled “CON_CAPXX”. The terminals of “CON_CAPXX” are labeled “GND_OUT” and “VCC_OUT”. These are to be connected as close as possible to the ground and positive supply of the Pulsed Load respectively. There are many power architectures where the supercapacitor may be placed. For example, the Pulsed Load may be a GPRS module or a DC/DC converter. For the least voltage droop (and maximum benefit from the supercapacitor’s low ESR) it is important to minimise the resistance between the supercapacitor and its load. Therefore the wires from “CON_CAPXX” to the Pulsed Load should be as short and as thick as practical. Warning: As stated in section 2.0, if VCC is chosen to be 5V then the voltage at the supercapacitor must be dropped to < 4.5V by including a series diode. The diode (D10) was chosen such that the minimum load current (quiescent current) gives an acceptable voltage drop. The minimum load can be increased by reducing the supercapacitor balancing resistors (R5 & R6). The CF specification states that the 5V rail is ± 10% and therefore (in theory) the rail may be as high as 5.5V. In this rare case a voltage drop of 1V is required. If D10 does not give enough voltage drop for the minimum current case then two diodes in series may be needed. Alternatively a diode with different characteristics can be substituted. Note: The number 1 pin of a header or jumper has a small triangle pointing to it. © cap-XX Pty Ltd, 2003 8 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 CF Card Under Test H O S T Pulsed loads Other Circuitry (eg GPRS Module, DC/DC converter) V+ GND Figure 2 Typical connection of Evaluation Board 7.1 VCC Modes Figure 2 shows the typical way for connecting the Evaluation Board. VCC on the CF Card Under Test is generally supplied by one of two modes. Mode 1, being the most common, is when VCC is supplied directly from the host (via “J_CF_HEADER” pins 13 and 38). These VCC rails supply all the circuitry on the CF Card Under Test (“Other Circuitry”) except for the “Pulsed loads (V+)”, which is supplied by the supercapacitor with the external wires. In this mode VCC is available to the “Other Circuitry” as soon as the CF Card Under Test is powered up, whereas the supercapacitor supply to the “Pulsed loads” is delayed by the charge up time of the supercapacitor according to equation 1. © cap-XX Pty Ltd, 2003 9 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 Connections common to both Mode 1 and 2 are; (a) Connect external wires (thick and short) from “CON_CAPXX” to the “Pulsed loads” on the CF Card Under Test. (b) Place jumpers on pins 3 and 4 of “J_VCC13_IN” and “J_VCC38_IN”. Remember to use the series diode (remove “J_5V”) if using the 5V rail. (c) Place jumpers “J_ENABLE”,. on “J_RED&YLW”, “J_GREEN”, “J_PGOOD” and (d) Remove jumpers on “J_VS1”, “J_VS2”. Mode 1 is accomplished by the following; (a) Connect jumpers on “J_VCC13” and “J_VCC38”. (b) Remove jumpers across pins 1-2 of both “JVCC_13_OUT” and “JVCC_38_OUT”. Make sure that VCC on the CF card under test is not connected to the Pulsed Load V+. Otherwise VCC will be short circuited by the supercapacitor when it is discharged and the current limit circuit is not in this path. Mode 2 is when the supercapacitor supplies both the VCC for the PC Card Under Test (“Other Circuitry”) as well as the “Pulsed loads”. In this mode all supplies are delayed according to equation 1. Any voltage ripple on the supercapacitor due to large currents will appear on the VCC rail. Mode 2 is accomplished by the following; (a) Remove the jumpers on “J_VCC13” and “J_VCC38”. (b) Either ensure that VCC on the CF card under test is connected to the Pulsed Load V+ and supply the load via thick wires as per Figure 2 or place jumpers across pins 1-2 of both “JVCC_13_OUT” and “JVCC_38_OUT”. There are many other modes available. The Evaluation board is designed for flexibility by allowing each section to be isolated or connected to external circuits. NOTE: Care must be taken, in which ever mode is chosen, so that the charge up time of the supercapacitor does not affect the operation of any reset or power rail monitoring circuitry etc. As described in section 4.0 and 5.0, the “J_ENABLE” and “H_PGOOD” signals may need to be interfaced with the CF Card Under Test for proper control. 7.2 Current Measurement Currents can be measured with a current probe or a voltage across a sense resistor. A jumper can be replaced by an external wire loop which the current probe can clamp on. If a current probe is not available then a sense resistor can be used in © cap-XX Pty Ltd, 2003 10 www.cap-xx.com APPEB1004 User’s Manual, Rev. 1.0, March 2003 place of the jumpers. The voltage dropped across the resistor divided by the value of the resistor equals the current. 7.3 Card Detect The correct insertion of a CF Card is detected when both pins 25 and 26 are grounded. These pins are typically grounded on the CF Card Under Test. However, the ground signal can also be replicated by jumpering –CD1 and –CD2 to ground on “J_Test1” and “J_Test2”. The removal and insertion of the card can be simulated by depressing and releasing either of the two micro-switches “SW_CD1” or “SW_CD2”. 7.4 Voltage Select The CF Card Under Test chooses the VCC voltage rail using pin 33 (-VS1). If -VS1 is grounded then a VCC of 3.3V is requested, if it is left floating then 5V is requested. This signal can be replicated with “J_VS1”. Placing a jumper on “J_VS1” forces the signal to ground and therefore requests 3.3V. “J_VS2” is undefined and should be left floating. 8.0 Disconnecting Circuits for Reduced Load The minimum voltage on some loads may be critical. Any current that the Evaluation Board uses contributes to the droop on the input voltage. If the droop becomes excessive then some of the functions on the Evaluation Board can be disconnected to save current and therefore increase the input voltage. The red and yellow LEDS can be disconnected by removing the jumper “J_RED&YLW”. The green LED can be disconnected by removing the jumper “J_GREEN”. The entire PGOOD circuit can be disconnected by removing the jumper “J_PGOOD”. © cap-XX Pty Ltd, 2003 11 www.cap-xx.com APPEB1003 User’s Manual, Rev. 1.0, February 2003 Appendix Schematic The supercapacitor and current limit circuit can be isolated by removing the jumpers on J_VCC13_IN, J_VCC38_IN, J_VCC13_OUT and J_VCC38_OUT. 1 Remove jumper J_5V if the rail is 5 Volts. This gives a diode drop to keep the supercap under 4.5V. VCC_IN 1 M1 SUD45P03-10 22m TP7 JUMPER1 J_5V R3 10k C2 D1 TP8 1 1 2 C1 47n R2 2k LM4041DIM3-1.2 D10 22k R7 22 TP9 R10 3 M2 - FDV302P R5 39k 1 CX1 3 R8 39k 470 3 H_CAPXX R9 1 + J_VCC13_IN CON4 Vcapxx TS1852 8 2 1 10k R4 10k 47n VCC_IN R6 RS1A 1 2 3 4 CON4 J_VCC38_IN R13 680 R1 VCC_IN 2 + The intensity of the Yellow LED gives an indication of the voltage on the supercap when VCC_IN is disconnected, but only when J_5V is connected. D8 R11 BAT54J 470 D2 VCC_IN TP5 1 50k R15 Vcapxx FDV301N C4 47n TEST POINT 1 TP6 VCC_IN TS1852 4 6 J_Enable can have its jumper removed and can be driven by an external open collector if desired. 2 J_ENABLE - 5 + JUMPER1 Power Good Circuit. If H_PGOOD is high then the supercap rail is good. TP4 R16 3k9 R17 22k C3 100n Place cap close to pin 8. J_RED&Y LW Y ellow_LED Schottkys 1 capxx M3 U1A Vr 1 4 1 2 3 4 R14 4k7 2 JUMPER1 1 - D5 ZRC250 2 2 R 8 R20 22k H_PGOOD R19 7 1 U1B VCC_IN 3 TP3 1 R12 BAT54J 220 D3 D4 R23 1 1 1 R21 TP2 1 BZX84C3V3 Q1 BCX20 4k7 TP1 2 R22 + R23 = 22k*2.5/Vw JUMPER1 3 Red_LED D6 Green_LED JUMPER1 2 500k R22 2 D7 ZRC250 47k D9 R18 470 2 680 1 1 2 Vw = width of hysteresis Vh = high threshold Vr = reference 2 JUMPER1 CON2 J_GREEN JUMPER1 Vr = Vh/(Vw/2.5+2) J_PGOOD CON_CAPXX CON_CAPXX is to connect low resistance leads from Vcapxx to the CF card so there is a low resistance path from the supercap to the load. 1 Linking all POWER GOOD grounds and then jumpering to common ground allows the POWER GOOD circuit to be disconnected. SW_CD1 Normally Closed These spring loaded switches simulate card removal and insertion. D2FL Normally Closed SW_CD2 If VCC_IN is 5V then both the Red and Yellow LEDs will be on. If VCC_IN is 3.3V then only the Yellow LED will be on. These LEDs will also be powered by the supercapacitor through the body diode of the current limiting Mosfet when VCC_IN is disconnected by the host. The LEDs can be disconnected so as to not load the circuit. D2FL -CD1 and -CD2 can simply be grounded with jumpers across pins 25&26 on J_Test2 and pins 25&26 on J_Test1 respectively. J_VCC13_OUT CON3 1 2 3 J_Test1 1 3 5 7 9 11 13 15 17 19 21 23 25 J_Test2 2 4 6 8 10 12 14 16 18 20 22 24 26 JUMPER13 1 3 5 7 9 11 13 15 17 19 21 23 25 2 4 6 8 10 12 14 16 18 20 22 24 26 1 2 3 J_VCC38_OUT CON3 J_VCC13_OUT, J_VCC38_OUT, J_VCC13 and J_VCC38 can have their jumpers removed and an external supply can be connected to J_VCC13_OUT (pin 2 or 3) and J_VCC38_OUT (pin 2 or 3) if desired. JUMPER13 J_CF_SOCKET J_CF_HEADER 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 GND D03 D04 D05 D06 D07 -CE1 A10 -OE A09 A08 A07 VCC13 A06 A05 A04 A03 A02 A01 A00 D00 D01 D02 -IOIS16 -CD2 -CD1 D11 D12 D13 D14 D15 -CE2 -VS1 -IORD -IOWR -WE IREQ VCC38 -CSEL -VS2 RESET -WAIT -INPACK -REG -SPKR -STSCHG D08 D09 D10 GND HEADER 50 Placing jumpers on J_VCC13 and J_VCC38 passes VCC straight through to the CF card. In this case remove jumpers from J_VCC13_OUT and J_VCC38_OUT or the supercapacitor will short circuit the VCC rail. J_VCC38 JUMPER1 1 2 J_VS1 1 2 JUMPER1 1 J_GND 1&2 are test points to safely put the CRO ground aligator clip. J_GND1 1 J_GND2 2 JUMPER1 1 2 JUMPER1 The board can be configured such that it is a pure extender card with no extra loading or circuitry ie, all pins straight through. CONN SOCKET 50 J_VS2 2 JUMPER1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 1 2 Jumpering J_VS1 to ground ensures 3.3V. JUMPER1 J_VCC13 © cap-XX Pty Ltd, 2003 12 www.cap-xx.com APPEB1003 User’s Manual, Rev. 1.0, February 2003 PCB Top Overlay © cap-XX Pty Ltd, 2003 13 www.cap-xx.com APPEB1003 User’s Manual, Rev. 1.0, February 2003 PCB Top Layer © cap-XX Pty Ltd, 2003 14 www.cap-xx.com APPEB1003 User’s Manual, Rev. 1.0, February 2003 PCB 2nd Layer © cap-XX Pty Ltd, 2003 15 www.cap-xx.com APPEB1003 User’s Manual, Rev. 1.0, February 2003 PCB 3rd Layer © cap-XX Pty Ltd, 2003 16 www.cap-xx.com APPEB1003 User’s Manual, Rev. 1.0, February 2003 PCB Bottom Layer © cap-XX Pty Ltd, 2003 17