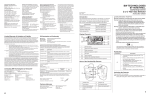

Download 128720 GAMicroClip User Manual (D5908-3

Transcript