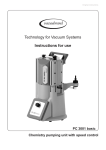

Download - Vacuubrand.com

Transcript