Download AquaBAT User Manual - Keynes Controls Ltd

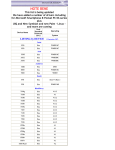

Transcript

Geotechnical Instrumentation User Manual & Deployment Guide For the AquaBAT Water Level Recording Instrumentation AquaBAT 17.5 and 22 mm diameter models Download the AquaBAT Guide at http://www.aquabat.net/downloads/Aquabat-user-guidev104.pdf Last updated July 2012 WHAT WE PROVIDE WARRANTY PROVISIONS Keynes Controls Ltd . warrants the AquaBAT range of loggers and Bluetooth interface for one year from date of purchase by the end user against defects in materials and workmanship under normal operating conditions. To exercise this warranty contact Technical Support at the phone or e-mail address listed below for a return material authorization (RMA) and instructions. Complete warranty provisions are posted on our website at http://www.aquabat.net The information in this document is subject to change without notice. Keynes Controls Ltd . has made a reasonable effort to be sure that the information contained herein is current and accurate as of the date of publication. Keynes Controls Ltd. makes no warranty of any kind with regard to this material, including, but not limited to, its fitness for a particular application. Keynes Controls Ltd will not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material. In no event shall Keynes Controls Ltd . be liable for any claim for direct, incidental, or consequential damages arising out of, or in connection with, the sale, manufacture, delivery, or use of any product. HOW TO CONTACT US Technical Support Keynes Controls Ltd Riseley Business Park Riseley Berkshire, RG7 1NW Tel: (0044) 118 327 6067 E-mail: [email protected] FIRMWARE & SOFTWARE UPGRADES The AquaBAT is upgrade able. Contact Keynes Controls Ltd. for details. If you suspect that your AquaBAT is malfunctioning and repair is required, you can help assure efficient servicing by following these guidelines: AquaBAT User Guide V1.04 Page 1 Table of Contents Page No. 3 4 5 6 Fibre Cable Installation Preparing the Fibre Optic Cable Attaching the Fibre Optic Cable AquaBAT O-ring Specification Preparation & Termination fibre into Header unit Stand-alone Deployments AquaBAT deployed at the Bottom Bore Hole / Stand-pipe Fixed Level installation Test to see that the AquaBAT is Functioning Optimising Fibre Signal Strength Protecting the Fibre Cable ends when not in use. Storing the AquaBAT when not in use Take care when deploying the AquaBAT 7 Bluetooth Header Unit Fibre Termination Cap 8 Installing Header Unit - Bluetooth Operations Only LED Boot Sequence Maintenance Procedures 9 Activating Bluetooth Fibre Header Unit In Microsoft Windows Mobile 6.0 10 Bluetooth Connection Not Setup 11 Care of the Fibre Cable Care of the AquaBAT Logger Unit Replacing the battery in the Bluetooth Header Unit AquaBAT Battery Replacement Service 12 Operating Environment Terminating Cable for Man holes Pump Testing Water Table & Ground Water Flow Monitoring 13 Measuring Level Reference Level Typical data logger deployment options for the AquaBAT Smart Phone / PDA Options 14 15 16 17 18 19 20 21 22 23 24 25 AquaSync Application Software List of files Software Download Loading software into a PDA/ Mobile Phone Software Windows Start-up Sequence Connection to the AquaBAT Water Level Recorder Signal Strength - Fibre Connection. Assigning a COM port for Bluetooth Communications Failure to Connect Common Communication Errors- Bluetooth Network Fibre Optic Cable Errors Bluetooth Device Name Multiple Header Unit Bluetooth Network Identification Software Functions Downloads Clearing the AquaBAT Memory by Resetting the Data Recording Files Config - Assigning Instrument Configuration Details Configuration Parameters - Assign Instrument Name, Assign Location Data Recording Operations Starting Data Recording Fibre Header Bluetooth Operations & Problems Trouble Shooting Guide Alarm Level Recording Confirm Parameters / make Changes Alarm Reference Levels Reference Point Duration of Data Recording Table Data File Format Spread Sheet Data Import Synchronising the Internal Clock / Setting the Time Zone Equations used to Determine Water Level Gravity Variations with Latitude How to determine local values of gravitational acceleration and altitude Making a level measurement Local Gravity Values Transient Protection Theory of Operations Faraday cage Why use Fibre Optic Communications AquaBAT User Guide V1.04 Page 2 Fibre Cable Installation The fibre cable installation instructions are the same for both the AquaBAT sensors and Bluetooth header units. Fibre Port AquaBAT User Guide V1.04 Page 3 Preparing the Fibre Optic Cable Fitting the fibre optic cable into the AquaBAT or into the Header unit does not require any specialist tooling or prior knowledge in the use of fibre optic cabling. In order to use it cut the cable to the correct length, allowing a few metres of spare cable in case the ends become damaged, and strip the outer sheathing away as specified for the instrumentation. The fibre optic cable is constructed in 2 parts and consists of an outer protective sheath and an inner plastic core. The outer sheath is 2.2 mm in diameter and the solid plastic core is 1 mm in diameter. Cut the sheath away exposing the solid plastic inner core. Simple wire strippers are more than adequate for this operation. When using the more expensive strippers set the stripping depth to no less than 1 mm. 0 5 mm Important Note. Take care that the end of the fibre is clean cut and is perfectly flat. Termination for connection to Header unit and sensor Optical edge cut at an acute angle will degrade the signal transmission through the fibre. Fibre cable cut with a flat optical edge. Attaching the Fibre Optic Cable AquaBAT 1. Ensure that the O-ring is seated firmly into the space at the top of the AquaBAT. Failure to do so may mean the fibre comes loose and disconnects from the instrument. 2. Slide the plastic termination cap onto the fibre cable through the central alignment hole 3. Check that the optical edge of the fibre optic is clean before inserting into AquaBAT. 4. Push the optical cable into the central hole in the AquaBAT until it goes no further. See below. 5. O-ring O-ring Specification BS005V75 Viton 75 shore hardness Slide the fibre termination cap down the fibre until light pressure is put onto the O-ring and align up the fixing holes in the cap to to screw holes in the top of the instrument. Fasten the cap to the instrument using the 2.5 mm mounting bolts. Take care to fit the screws as opposite pairs. Tighten the screws until the o-ring firmly grips the fibre cable. Testing the Fibre Cable Observe the free end of the cable unattached to the instrument and this will glow briefly. The better the fitting of the fibre into the AquaBAT the brighter the flash observed at the opposite end. Fibre Optic cable connected to the AquaBAT Unit 2.5 mm Preparation & Termination fibre into Header unit NP_Header Unit - Fibre Optic Interface 1. Check that the optical edge of the fibre optic is clean before inserting it into the Header unit. 2.. Push the optical cable into the central hole of the fibre port on the Header unit. (See opposite) The fibre cable is gripped and held into place by the retaining o-ring contained in the entry port. Once the cable is attached to the Header unit the AquaBAT data communications can take place. Mounting Bolts AquaBAT User Guide V1.04 When the fibre optic cable is not being used fit the protective plastic cap to keep the end clean. Page 4 AquaBAT Deployment Manual Version 3 Sept 2009 Maximum Fibre Cable Length = 100 m The photo opposite shows the fibre about to be fitted into the AquaBAT. The O-ring seal must already be fitted before the cap can be screwed into place. Once the termination cap is screwed into place the cable is attached to the instrument. Take care to fit the screws in opposite pairs and tighten such that the cap fits flush to the top of the AquaBAT. O-ring View looking into fibre port on the AquaBAT Stand-alone Deployments Data Download O-ring Specification BS005V75 Viton 75 shore hardness AquaBAT deployed at the Bottom Bore Hole / Stand-pipe This is the simplest of the deployment options for the AquaBAT and it is simply a matter of connecting the instrument to the fibre cable and deploying it down the bore hole. Once the AquaBAT is at the bottom of the hole simply lock off the cable gland and cut the fibre to suit the location. Fit several of the star washers to the cable above the cable gland to prevent the cable end from slipping. Alternatively, simply cut extra cable and terminate securely to the inside of the well head or on the man hole. floor. Fit the plastic cap to the end of the fibre cable when not in use to keep the cable head clean. Clean the Fibre end before insertion into the Header interface. Simply run the fibre under water or wipe with a cloth. Some moisture on the fibre when inserted into the Header unit or AquaBAT will have no affect on its operation. Fixed Level installation This is the most common method of deployment for the AquaBAT. For this type of deployment it is recommended that the fitting of a fixed position deployment bar (see opposite) is used to take the strain of the instrument when it is deployed, and to re-position the sensor should it be removed for maintenance. A Carabeana is attached to the bar and the Fibre cable is wrapped around it a number of times to prevent it slipping. The AquaBAT is deployed below the fixing bar to its permanent position. So long as the cable gland is tightly fastened and the star washers are attached to the excess cable then the sensor will be permanently placed and the results will reliable. No special care needs be taken to protect the fibre cable that protrudes from the top of the bore hole cover. When not in use fit the protective plastic cap onto the end of the cable. Where possible and when long term deployment is going to be carried out leave the excess cable in the top of the bore hole cover or man hole if one is available. The cable is plastic and so is safe from corrosion. AquaBAT User Guide V1.04 Page 5 Data Download Fixing Bar Multiple Turns of fibre cable secured around carabiner. Test to see that the AquaBAT is Functioning Optimising Fibre Signal Strength Direction of fibre Since the AquaBAT uses only light for data transmission The AquaSync software used by all of the the AquaBAT range then it is possible by simply looking into the optical port, of of sensors uses an scaling factor 0 - 1800 to indicate the level the sensor or the end of the fibre connecting to the header of light signal being received from the sensor. unit, to see if data is being sent. The received signal strength level has to above 40 for reliable Examination of the fibre cable attached to the AquaBAT communications to be undertaken. Should the signal level be will show a brief flash of light when the instrument attempts below this level then: to communicate. The signal flash is just observable to the naked eye and is a clear indication that the instrument is 1. Clean the fibre cable ends operating. 2. Reduce fibre length to shortest possible for application 3. Replace battery in the Header unit. An instrument under normal operation the flash rate is 1 4 Check that the fibre has been cut and fitted correctly. every 30 seconds. Direction of fibre Brief comm's signal flash Scarple or sharp scissors Illuminated LED in fibre optical port Protecting the Fibre Cable ends when not in use. Protective Cap When not in use Keynes Controls recommends that a cover/cp be fitted onto the end of the fibre cable. The cap will keep the end of the fibre clean and so make sure the signal strength between the instrument and the header unit is maintained at its optimum level when the cable is re-used. Protecting the Fibre Cable From Slipping If a cable gland is used to prevent the fibre cable from moving once an instrument has been lowered into place. Keynes Controls recommends the fitting of a number of Star Washers onto the cable as shown opposite above the gland. Star Washer on fibre Storing the AquaBAT when not in use If the gland becomes loose the the cable will only slip to the position When not in use the AquaBAT should be stored in of the washer and this will ensure that the instrument is not lost. its case or on a shelf with the optical port pointing If the AquaBAT is deployed to the bottom of the bore hole or tank then away from the sun. the washers need not be fitted. As the AquaBAT loggers communicate by light it is possible; however unlikely, that flickering sun light Take care when deploying the AquaBAT may accidentally start communications with the device. Keeping the optical port dark / out of Take care when deploying the AquaBAT that the possible light will prevent this event from fibre cable is securely fastened to the instrument. happening. This will also optimise the battery life. Raise the sensor slowly when lifting from the The storage temperature is - 30 deg to + 50 Deg C water and try to avoid and sudden movements of and so long as the instrument is maintained within the cable. these limits its long life is assured. When lowering the sensor into place make sure that the fibre cable is free from twists and unwinds from the drum in a normal manner. Leave a small amount of excess cable to make termination in a appropriate place and allow for repairs should the end of the cable become damaged. The details in this document are correct at the time of printing. Contact your supplier for the latest product details. Specifications and operations are likely to change without notice. AquaBAT User Guide V1.04 Page 6 Bluetooth Header Unit Fibre Optic Cable Port Battery Battery Supply: 2 x AA Cells Protective Plastic Boot Cover Power On/Off Front View Fibre termination cap View into fibre optic port of the header unit with the fibre securing block attached. AquaBAT User Guide V1.04 Page 7 Installing Header Unit - Bluetooth Operations Only 1. Ensure the fibre cable is prepared as detailed in page 3. 2. Push the end of the fibre cable into the optical port of the Header unit. The end of the cable clicks into the optical port as it passes through the o-ring seal. When multiple instrument downloads are to be undertaken there is no need to fasten the fibre optic cable into the Header unit permanently. The friction grip provided by the O-ring will give satisfactory results. For permanent installations the fibre termination cap will need to be fitted onto the optical port and this locks the fibre cable to the Header unit. 3. Fibre Optic cable fitted into Header Unit Power on the Header unit and so long as a AquaBAT is fitted the boot sequence is as shown below. As data is downloaded or configuration details are sent via the Bluetooth network and the instrument status LED’s flash indications operations underway LED Boot Sequence Initial Power On Start a Bluetooth Connection Made a Bluetooth Connection Data Transmission Green Power LED constantly illuminated Bluetooth LED status indicator flashes when making a connection to the Header unit. Bluetooth LED status indicator is now permanently illuminated. The Red Fibre Tx LED and Yellow Fibre Rx LED flash when data is being sent from the AquaBAT. When large amounts of data are being downloaded then the Red Fibre TX and Yellow Fibre Rx LEDs may appear to be permanently illuminated to the eye. Flashing LED At slow sample rates when observing real-time data the individual Rx and Tx status LED switch on and off slowly. Maintenance Procedures Fibre Optic Header Unit The Header units are robust and splash proof . The fibre optic port of the Header unit is a sealed device and is manufactured from 316 or better stainless steel and under normal conditions is safe from corrosion and damage. 1, Cleaning the fibre optic port. Remove fibre termination cap by undoing the 4 x 2.5 mm bolts on the header units Clean the fibre optic port by washing with de-ionised water, or if serious fowling use water with mild detergent. and a cotton wool bud to remove any material. Allow plenty of time for the port to dry out before re-using the Header for additional downloads. The fibre port will operate even when wet as water ingress has little effect on the light transmission. Note there can be signal attenuation when operating with water in the fibre port. For optimum results make sure the unit is dry. 2. Replace the 2 X AA batteries fitted inside the Bluetooth Header unit typically after 500 downloads or after excessive use. Should a sensor suddenly fail to operate then there is a good chance the batteries in the Header unit needs replacing. When the batteries are low then unusual behaviour of the status LED indicators may be observed. AquaBAT User Guide V1.04 Page 8 Activating Bluetooth Fibre Header Unit in Windows Mobile 6 The instructions below show how to install the fibre Header unit on to a Bluetooth wireless network used in a Windows Mobile 6 operating system. The operating system can be part of a mobile phone, PDA or any other similar communications device. Details can change without notice. Refer to your operating system manual additional details. Important Note Before attempting to use the fibre header unit ensure that the Bluetooth interface in the PDA or mobile phone is switched on. Carry out this operation for each individual Fibre Header unit being used by the recording device. Instructions Using the ‘Settings’ option within the operating system. The following Windows will appear. Select ‘Connections’ Tab icon Select ‘Bluetooth’ configuration operations. to start The Windows Mobile 6 will show Windows similar to to those opposite while configuring a Bluetooth device. Activate the Bluetooth Manager to Add the Fibre Header unit Bluetooth to the PDA/Mobile Phone. Bluetooth Manager A Window similar to this one will appear. Other devices such as hand free or Sat Navigation systems may have icons that appear here. Important note The AquaBAT Fibre Header unit does not use data encryption for data transmission. Select ‘New’ Tab Select’ Explore a Bluetooth Device’ Remove any data encryption options for the Fibre Header unit Bluetooth configuration. This will not effect any encryption used by any other device used by any other Bluetooth device and is only a feature of this device. Windows Mobile 6 sets up encryption for use with the header units by default. This has to be removed for reliable operations. AquaBAT User Guide V1.04 Page 9 to operate a new Header unit. Make sure the Header Unit is switched on and that the Power Status LED is illuminated. The Fibre Header unit appears under the icon labelled ‘Blogger-n’ where n = number of units associated with the data recording device (PDA/Mobile phone) See “Communications Wizard” window for example of a PDA with 3 Fibre Header units associated to it. Activating Bluetooth Interface within the Fibre Header unit for data communications Once the Bluetooth interface within the Header unit has been identified by the PDA/Mobile Phone then it has to be set to operate correctly for data downloading. Using the “Bluetooth Connection Wizard” Window opposite simply 1. Select ‘SPP’ option within the “Service Selection” list 2. Disable the ‘Security’ Tab Select ‘Next ‘ option at the bottom of the Window The operating system will respond ‘Shortcuts Created’ once the process is completed. The new Header unit will now operate with the AquaSync software. Bluetooth Connection Not Setup If a new Fibre Header unit is being used with the AquaBAT and this device has not been correctly identified by the Bluetooth network then the applications software will not operate. In the case of the AquaSync software no communications will be made between the Header unit and the PDA and the main window will show “Communications Error” AquaSync software window when no Bluetooth communications from the Header unit is available AquaSync software With no Bluetooth network connection With configured Bluetooth Network Initial AquaSync window when initialising data communications. AquaBAT User Guide V1.04 Page 10 AquaSync software showing fully operational Bluetooth communications Care of the Fibre Cable The fibre cable should in fact be trouble free as it is safe from corrosion and cannot be damaged by lightening strikes. Some wear and tear at the ends of the fibre where it is terminated into the AquaBAT and into the Header unit is expected. 3. After a successful deployment remove the bolts holding on the fibre termination cap from the AquaBAT take out the fibre. Check the end of the fibre for wear and signs of stress damage due to the pressure asserted by the O-ring. Should and stress damage be observed simply cut back the fibre and re-fasten onto the sensor. See details on page 3. Cut back the fibre as described on page 1 and re-attached the cable when necessary. Care of the AquaBAT Logger Unit After a successful deployment the AquaBAT should be cleaned before being re-used. Make sure the Fibre termination cap is removed before cleaning. Remove the O-ring from the fibre entry port 4. Wash the AquaBAT in fresh water to remove any contamination on the case. Clean the optical port to remove any signs of accumulated dirt in the optical port. Use a mild detergent and cotton wool bud to remove any contamination and material build up in the fibre port. O-ring Fibre termination cap Replacing the battery in the Bluetooth Header Unit 1 1. 2. 3. 4. 5. 3 2 Remove the Header unit from the protective plastic boot cover. Slide the battery access panel off the case and lift out the old AA batteries. Fit the new battery onto the connector and fit the cover plate Switch on the Header unit using the On/Off button. The Power status green LED will illuminate. Fit the Header Unit back into the protective plastic boot cover. AquaBAT Battery Replacement Service The AquaBAT has to be returned to Keynes Controls for a new battery to be installed. Battery Compartment Cover Rear of Header Unit Special tools are required to remove and install the battery and this cannot be undertaken by the User. All sensors are re-calibrated after a battery replacement is carried out. There is a charge for this service. AquaBAT User Guide V1.04 Page 11 Operating Environment The AquaBAT will function satisfactorily in the worst of environmental conditions. The instrument is of solid construction and does not use any vented signal cabling which is the main point of weakness due to corrosion causing leaks for competitive products. For inland water ways the AquaBAT is supplied in a stainless steel 316 or better casing. For salt water applications a Titanium enclosure version instrument can be supplied. Vent Terminating Cable for Man holes The fibre optic cable linking the header unit to the AquaBAT is deployed with greater length than is actually required and the excess is looped and stored at the bottom of the man hole. For best operation maintain several meters of cable is left at the bottom of the man hole to enable the operator to easily fit the Header unit into a convenient location when required. Take care to fit the plastic cap over the end of the cable when not in use. Should the fibre cable become damaged simply cut back and strip the sheathing as detailed on page 1. Man hole Fibre Optic Cable Overburden Impermeable Layer Pump Testing Setting the AquaBAT to high speed recording, and using it deployed with a in-situ bore hole pump the characteristics of the water flow around the pump can be determined . Water Bearing Layer Along with pump testing, impulse water level interaction can equally be monitored using the AquaBAT. The water level readings can be seamlessly integrated to the pump operations and water levels against time plotted. AquaBAT Logger Bore Holes B A Water Table Capillary Fringe Flow of ground water Typical Pump Test Water Flow Water Table & Ground Water Flow Water Table & Ground Water Flow Monitoring Using a number of bore holes at widely spaced locations and the ability of the AquaBAT to synchronise data by virtue of its use of its temperature compensated clocks offer high stability. It is possible to monitor the water table levels across defined land masses and to get some indication that water flow is taking place by the change in water temperature. The ability to take reading from a series of locations enables the water table gradients to be followed through the different perm abilities of the local ground conditions. With a well planned and maintained water monitoring system effects on the water table can be observed due to changes caused by local building operations. Description Notes O-ring BS005V75 Viton 75 shore hardness Outside diameter 5 mm Mounting Bolts 2.5 mm Hexhagonal head Thread size: M3 Height, external:10 mm Cable Gland 2 - 5 mm Brass Table of Consumable Parts AquaBAT Deployment Manual Version 2 Sept 2009 AquaBAT User Guide V1.04 Page 12 Measuring level The AquaBAT determine the height of a water column above the sensor by measuring water pressure. A version of the AquaBAT set to measure a range of 1 bar but calibrated to record barometric pressure is used available when local barometric levels are required. The barometer version of the AquaBAT has part number AquaBAT-bar. The AquaBAT is a very accurate device and can be setup to allow for local gravity, salinity and temperature. The sensor automatically allows for varying temperature when taking a reading and storing data. The AquaBAT is an intelligent sensor and as such can return water level data in a number of different engineering units. The output values from the AquaBAT have to be in the same engineering units as the barometer for the optimum water level measurements to be achieved. Typically both the AquaBAT level recorder and the AquaBAT-bar use units of mH20 for stored data. The compensated water level values can be related to a reference point such as the top of the standpipe tubing at ground level, or some other convenient reference level. To undertake this operation and in the event that the exact length of the fibre cable being unknown, the distance between sensor head and the desired reference point needs to be measured and can be manually entered into the Connect software during a download. Typically the initial water height as measured from the top of the bore hole head using a water dip meter is used as the reference point. Fibre-optic Cable The water level measurement made using a dip meter is independent of barometric pressure and is an absolute measurement. This makes it an ideal reference datum point. Borehole Head Datum Barometer The Reference Level used within this application is the distance manually measured from a Datum level, normally the top of the measuring tube to the water level obtained independently using a water level meter (Dip-meter). The reference point establishes the depth of the AquaBAT and allows readings of the AquaBAT to be converted into readings referenced to the Datum level. HDepth-to-water If the elevation of the Datum level is established relative to national datum ( Ordnance Datum or Port Datum) then water levels from other wells can be compared related to a common datum. It is necessary to record the time at which the Reference Point is measured so that the AquaBAT reading can be used at the same time. Water Level Reference Level HReading HCable An AquaBAT-bar barometric logger is used to measure the air pressure variations for every measurement area. Typically only a single sensor is needed for each 20 km2 area. Compensation for these air pressure variations can be made quickly and efficiently using the Connect Logger software package. Sensor Level Example: HDepth-to-water = Depth to water ( Reference Point) = 15.62 m HReading = AquaBAT Reading = 10.52 Calculated depth of AquaBAT relative to Datum Level = 15.62 + 10.52 = 26.10 m This value of 26.10 is used to calculate Depth to water subsequently e.g. AquaBAT reading = 5.10 Depth to water relative to Datum Level = 26.10-5.10 = 21.00 m The Reference point should be re-established on a routine basis to ensure quality assurance by an independent means of the verification of the data. Additionally, correct use of the Reference point will improve accuracy of readings, particularly at high pressure heads on the AquaBAT. . AquaBAT User Guide V1.04 Page 13 Typical data logger deployment options for the AquaBAT The image below demonstrates how the AquaBAT is connected to a data logger for stand-alone operations. Fixed installation data recording systems or GPRS remote access solutions can be provided. Bluetooth-Fibre Header System PDA/Mobile Phone The follow image demonstrates how data is downloaded from the AquaBAT water level recorder using a Bluetooth cable free interface to a PDA/Mobile phone AquaBAT User Guide V1.04 Page 14 Smart Phone / PDA Hardware A sample list of PDA /Mobile Phones suitable for running the AquaBAT applications software is: Hewlett Packard HP iPAQ Models HW9615, RW6815, HX2190, RX5935, HX2750 HW6510, HX2100, HX4700, RX5720, HW6910 Motorola Q9, Sidekick, HTC HTC S620, HTC P6500. HTC P3470, HTC P3600, HTC Advantage The minimum specification for operating the AquaSync application software on any Smart phone or PDA is: Windows Mobile 5.0 or greater operating system. 320 x 240 Graphical Colour screen - Touch sensitive (ideal) AquaBAT User Guide V1.04 Page 15 AquaSync Application Software The following pages describe the installation and use of the AquaSync application software used with the AquaBAT range of water level recorders. List of Files The software consists of a single file: AquaSync.exe Software Download The AquaSync software is freely available and is downloaded from http://www.aquabat.net/software/AquaSync.exe http://www.aquabet.net/software/AquaSync.zip Loading software into PDA / Mobile Phone The simplest way to download the AquaSync software into a PDA/Mobile phone is to use a device with a built in GPRS modem or WiFi interface from a Hotspot and to download the software directly from the Keynes Controls web site. Save the Download and activate to run. Download the AquaSync.exe file and store it to a suitable Flash memory card. Fit the memory card in to the PDA/Mobile Phone and activate the software from here. Use the Flash Memory card to provide additional storage for data downloads from the instruments. Refer to the product User manual Software Windows The images below show the different Windows presented to the User from within the AquaSync software. All the operations required to operate a AquaBAT water level logger are shown below: The default Window once the AquaSync software is initiated is the “Connect” Window. It is from here that communications to the instruments is started. Selection of the additional Windows is simply by selecting the Tabs at the bottom of the screen The Instrument configuration details are displayed once communication is made to logger. Connect Window Use the Tabs at the bottom of each Window to navigate through the software. Make sure that an instrument is connected to the Header unit in order that the Green indicators shown opposite are activate. The screens can look different if running the software with no logger fitted. AquaBAT User Guide V1.04 Download Window Page 16 Logging Window Config Window Software Start-up Sequence The following images show the sequence the Status indicators on the PDA software follow when connecting to the AquaBAT water level recorder via the Fibre Optic Header unit to a PDA/Mobile phone for data down loads and/or Configuration changes. Connection to the AquaBAT Water Level Recorder. 1. Ensure the fire optic cable is connected from the AquaBAT into the Header unit. Power on the Header unit and observe the green LED status indicator flash showing that the battery within the unit is of a suitable level for operations. To connect to a AquaBAT water level logger Select “Connect Tab” from with AquaSync software. The sequence of images below will be displayed automatically as communications to the AquaBAT is activated communications to the Header unit and AquaBAT are made. Initial Screen - No connection Bluetooth connection made and communications started Bluetooth communications operating and communications to the AquaBAT initialised Full communications to AquaBAT across the Bluetooth interface Initial signal strength indication being made The signal strength indicator shows the received signal strength at maximum level (100%) Signal Strength - Fibre Connection The signal signal strength indicator is only provided as an aid to show how well the fibre optic cable has been connected to the instrumentation and used as a guide only. Communications can be carried out reliably with a signal strength indicator value above 20. So long as Status indicators on the Connection screen are both green then communications can be reliably carried out. Status Indicator Bluetooth Cable Free network Status Indicator Fibre Optic Connection Fibre Optic Signal Strength Indicator Connect Tab Copyright AquaBAT 2011-2012 Keynes Controls Ltd with holds the right to change the specification without notice. AquaBAT User Guide V1.04 Page 17 Assigning a COM port for Bluetooth Communications The following section details the selection of the COM port within a mobile phone or PDA for Bluetooth Communications to the Fibre Optic Header unit. Initial Setup Only For the initial operation of the Bluetooth network with a Header unit only. 1. Select “Connect” Tab Select the COM port from the available list in the drop down box. For PDA operations select Ports 6 or 7. For mobile phone selection - refer to Manufacturers User Manual. Once the COM port is identified and associated with the Bluetooth communications then it is stored automatically for later use. Simply activate the AquaSync software from the File manager and the port should automatically be assigned. Failure to Connect If the Bluetooth connection from the PDA/ Mobile phone is not set-up correctly then any attempt connect into the Header unit will not be successful and the Window opposite will be displayed. COM port selection Check the Bluetooth configuration and retry the connection. Connect Window Failure to Connect Window Common Communication Errors - Bluetooth Network. If it is not possible to communicate with the Header check the following: Low signal power often means the fibre cable is not correctly fitted or the ends are badly finished. It is important that the fibre optic cable is accurately terminated with a flat clean cut edge to allow for maximum light transfer. 1. The batteries within the Header unit are low. 2 x AA Batteries - replace where necessary. The green power indicator LED will flash when the Header is powered on. 2. Ensure that the Bluetooth cable free network is associated to a COM port - See Manufactures guide for Mobile Phone or PDA 3. Ensure that the Header unit and PDA/Mobile Phone Bluetooth network are within range of each other and within the operational range which is typically 10 m. Fibre Optic Cable Errors 1. Ensure that the Fibre optic cable is correctly terminated into the AquaBAT and Header Unit. Ensure that the Fibre optic cable is cut correctly so it fits flat to the sensor in the Header unit and AquaBAT. Bluetooth Device Name Select “search new devices” on Connection option within Mobile Phone / PDA applications. Allow the mobile phone / PDA to search for a new device in exactly the same procedure used to connect to a Hands-Free sets. The mobile phone / PDA Bluetooth communications software will identify the Header unit as “AquaBAT” Select “AquaBAT” -- The Header unit has now been identified and communications can be carried out. Multiple Header Unit Bluetooth Network Identification Should there be several header units within range of the Bluetooth connection then they will be identified as AquaBat N eg AquaBat1 , AquaBat2 etc .... AquaBAT User Guide V1.04 Page 18 Software Functions The software functions within AquaSync is broken down into 4 separate parts: Connect Download Logging Config Each is selected by Connect - Network Status Indicators for Fibre optic and Bluetooth connections. Enables connection to a single AquaBat instrument and selection of the COM port for blue tooth data communications. Signal strength indicator between the AquaBAT and Header unit. Download - Set Reference point for water level Shows real-time water level and temperature Download status - number records available within AquaBAT Shows file into which data is being stored during the download Logging - Re-synchronise clocks, Clear AquaBAT memory and restart logging. Config - Logger Name, Location, Sampling Period, Alarm high level Alarm low level, Alarm logging period. Software Selection Tabs Download 1. Select “Download” Tab The configuration details for the AquaBAT is automatically downloaded during the connection operation shown in the Download Window . 2. Press “Download” button to obtain data from the AquaBAT. The data storage file is automatically created with a unique file name consisting of the date and time of creation and s is Comma Separated format (CSV). The example below shows data being archived into filename “blog2008_01_26_20_31_46.txt” Reference Point (User Defined - Optional) Communications Status Indicators Real-time Temperature (Deg C) “Start Download” Button Real-time Water Level (m) Number Records Transferred Data Download Filename % of Records Downloaded Comma Separated Variable data file The total number of records available for download is shown in this Window. While the records are saved to file a real-time counter indicates the percentage of records that have been archived. 100 % indicates that the all records have been stored. Download Tab The Download Window updates automatically showing the number of records that have been archived and with the current real-time sensor value. Data recording within the AquaBAT stops while information is being retrieved. The Download Windows opposite show a typical retrieval in operation. AquaBAT User Guide V1.04 Page 19 Clearing the AquaBAT Memory by Resetting the Data Recording Files The instructions below only refer to “deleting the data file within the AquaBAT” and this operation does not effect any other configuration or parameter that has been set. Care must be taken when performing this operation and it should only be carried out after data has been downloaded and stored. Please carefully verify the data files are correct before deleting any data within the instrument. Ensure that the Logging Window is selected. 1. Press the “Restart Logging” button The Restart Logging Warning message will appear as shown opposite. Press the “OK” button and the data file is deleted and reset to 0 Record size. Take care when deleting data from within the instrument as this action cannot be recovered should the memory be cleared. Config - Assigning Instrument Configuration Details The following sections details how to configure the AquaBAT for Data Recording and Alarm Level Data Capture. Features There are 2 independent modes of operation for the AquaBAT and these are: 1. Data recording at a fixed interval in time - ie every second / minute / hour - Defined as Period 2. Alarm Level Data Recording - Information can be gathered at a faster rate and in greater detail than the standard data recording and can be activated only when the pressure / water level goes outside set alarm conditions. Defined as Trigger Configuration Parameters Logger Name Location Period Trigger 20 x Char 20 x Char - Can be any user defined parameter - Map Ref / name Data Recording Period - 1s, 5s, 10s, 30s, 1 min, 2 min, 5 min, 10 min, 15 min, 30 min, 1 Hr Alarm Level Period - 1s, 5s, 10s, 30s, 1 min, 2 min, 5 min, 10 min, 15 min, 30 min, 1 Hr For call configuration operations 1. Select “Config” Tab and the “Config Window” below will appear Assign Instrument Name Enter the Instrument name in the box titled “Logger name” - to confirm press the “Set” button. Assign Location Enter the Instrument location in the box titled “Location” - to confirm press the “Set” button Data Recording Operations The instrument operates stand-alone and takes a new reading after a fixed time period. Select “Period” box and a list of logging time periods is displayed. Select a time period for the data acquisition operations and press “Set” button to confirm. Example. To set the data recording at 1 min intervals select the “1 min” option. Starting Data Recording To Start Data Recording select the “Tick box” adjacent to the “Data Recording” menu option. AquaBAT User Guide V1.04 Page 20 Fibre Header Bluetooth Operations & Problems Trouble shooting Guide The fibre header unit needs to be connected to a downloading device such as a PDA or mobile phone before data can be downloaded from the AquaBAT. This document covers Microsoft Mobile 6.0 version operating system only and meant as a guide only. Other versions of the operating system will operate but may shows slightly different Configuration Windows than shown below. Multiple Header Unit When using multiple Fibre Header units each one must be individually setup to the Bluetooth network in the PDA / Mobile phone. For example if a PDA is being used to download information from a number of fixed installations at multiple sites then each Header unit will have to be configured onto the Bluetooth network. Stand-alone systems with their own Fibre Header units. Note Windows Mobile 6 PDA / Phone The Windows Mobile 6 operating system is supported on a wide range of products. h ot to ue Bl m Co Aquabat-1 Aquabat-3 ns tio ica un m Bluetooth Instrument Names The AquaSync software will operate on any device supporting this operating system and including a Bluetooth data connection. Common downloading devices for AquaBAT at PDA and mobile phones. Aquabat-2 When using multiple Header units then you should see each one listed in the Bluetooth setup of the PDA/Phone similar to the way it is shown below. Only when the Bluetooth interface on the Fibre Header unit is correctly identified by the PDA will the AquaSync software operate correctly as as shown opposite. Details in this document can change without notice. Refer to the PDA/Mobile phone manual for in depth operation of the Microsoft operating system. If the Bluetooth network is not setup correctly then the above screen will be all appears upon activating the AquaSync software. AquaBAT User Guide V1.04 Page 21 Alarm Level Recording The Alarm Level recording enables data to be acquired at a different rate to the standard data acquisition operation when the water level exceeds pre-set conditions. When the Alarm Level data is recorded at a higher rate that the normal data recording operations it allows the water level to be observed in greater detail and is ideal for pump tests and monitoring flood conditions. Alarm Conditions The Alarm Level Recording is only active when both Low and high settings are defined. Deeper Than (m) - defines the level in m for which the water level must exceed before data is stored. Shallower Than (m) - defines the minimum level that the water level must be less less than before data is recorded. To activate Alarm Level Recording select the “Tick box” adjacent to the “Alarm” menu option.. Ensure that the Alarm levels are defined before activating the Alarm Level recording, Communications status indicators These must be green for Configuration to be undertaken. AquaBat Name The Window opposite demonstrates a AquaBAT configured to record alarm levels when the water level exceeds 12.5 m or is less than 1.2 m at a sample period of 10 seconds. Location Alarm Level Recording logging period Data Recording activation tick box Alarm level high Alarm level high Alarm Level Recording activation tick box Alarm Level Recording logging period Config Tab Press Set Button to store Config parameters The normal data acquisition rate is shown to be 5 seconds. The “Tick” boxes for the Alarm Level and Data Recording operations are shown selected. Confirm Parameters / Make Changes Once the Configuration parameters are set or changes are made then they are only stored permanently into the AquaBAT upon activation of the “Set” button. Con fig Window Alarm Levels Reference The figure opposite demonstrates how the alarm levels are configured when using Alarm Level Recording. The alarm levels are based upon water level above the sensor only and the units are set in metres. Reference Point Top Bore Hole Reference Point Shallow level alarm The Reference Point used within this application is a distance measured from a Datum level and this is generally used to fix a Bore hole height with respect to Mean Sea Level. For local measurements the Reference Point is generally taken as the initial level of the water below to top of the bore hole. See diagram opposite. High level alarm Time Period Duration 1 s 5 s 10 s 30 s 1 min 2 min 5 min 10 min 15 min 30 min 1 Hr 55 11 23 69 138 277 694 1388 2083 4166 8333 AquaBAT User Guide V1.04 hrs Days Days Days Days Days Days Days Days Days Days ** Duration of Data Recording Table The AquaBAT contains 200,000 records for data storage and has a operating life of 10 yrs depending upon the number of downloads undertaken and the sample rates being used. The table below gives the operating duration for the pre-set logging rates to fill up the internal memory of the instrument . Page 22 Data File Format The files created by the applications software is in Comma Separated Variable (CSV) text format. The configuration layout is shown below. CSV means that new data items within a line are separated by a Comma. #Name=10bar-Sensor #Location=swindon #Ref Point=1.20000 Borehole Logger 0001 Time,Pressure,Temperature Timestamp,Bar,Celcius 31 Jan 2008 14:06:20 +0000,0.179000,10.469999 31 Jan 2008 14:06:30 +0000,0.179000,10.500000 31 Jan 2008 14:08:10 +0000,0.179000,10.440000 Sensor Name Deployment Location Reference height Instrument Serial Number Column Titles Engineer Units for the columns Spread Sheet Data Import The image opposite shows a sample of data imported into the Microsoft Excel package. Most modern applications software accept CSV format data and the results can be easily tabulated and processed without any special software. Synchronising the Internal Clock / Setting the Time Zone The internal clock of the AquaBAT is very accurate and is temperature compensated. Over time the clock can drift and may be reset by the User at any time. By default the AquaBAT internal clock is set to GMT with no offset. Any offset due to operation in another time zone has to be applied to the instrument. The following instructions demonstrate how to set the internal clock of the instrument. 1. Ensure that the “Logging” Window is selected. Press “Re-synchronise Clocks” button The instrument clock will now be set to the clock of the PDA / Mobile Phone running the Connect software. During the writing of any configuration information the instrument temporarily suspends the data logging operations until the action is completed. Adjusting the Time Zone The Connect application software detects the internal time and date of the device running the software. Therefore if a PDA / Mobile Phone is set to operate in a different time zone to the default setting of the instrument then the new time will be uploaded upon selecting the “Re-synchronise Clocks” button. Copyright AquaBAT 2011-2012 Keynes Controls Ltd with holds the right to change the specification without notice AquaBAT User Guide V1.04 Page 23 Equations used to Determine Water Level The following equations are used to correct the water level height for variation in Altitude, Temperature, Local changes in Gravity and density of water. Gravity Variations with latitude Precise values of g (Gravity) vary depending on latitude on the Earth's surface. The standard acceleration due to gravity at the Earth's surface is, by definition, 9.806650 m/s² (32.17405 ft/s²). This quantity is known variously as gn, ge (though this sometimes means the normal equatorial value on Earth, 9.7803 m/s²), g0, gee, or simply g (which is also used for the variable local value). Pressure = . g .h where = Density Kg/m3 g = Gravity m/s2 h = Height of fluid column in m How to determine local values of gravitational acceleration and altitude? The variation in the value of g across the earth's surface is about 0.5 % due to latitude, plus a change of approximately 0.003 % reduction per 100 m altitude. Local topography and tidal forces also can have small effects. An approximate value for g, at a given latitude and height above sea level, may be calculated from the formula: g = 9.780 327 (1 + A sin2 L - B sin2 2L) - 3.086 × 10-6 × H m·s-2 where A B L H ge = = = = = 0.005 302 4 0.000 005 8 latitude height in metres above sea level Equatorial value gravity = 9.780327 m Reference UK National Physical Laboratory http://www.npl.co.uk/mass/faqs/gravity.html The AquaSync software is preset to use ge = 9.780327 (Equatorial) value of gravity by default, however a more accurate reading can be determined by adjusting the default value of g to suit the values shown at the locations in the table below. If the sensor variation in altitude from the locations below is known then reduce the listed value by 0.003% per 100m increase in altitude. Making a level measurement Level = mH2O pressure at 4 C The corrected level measurement is * 1 Density of water 9.80665 Local Gravity Density (fresh water) = -6.017777E-6t2 + 0.000041t + 0.999841 and t = temperature in C where density of water is defined as Local Gravity Values Amsterdam 9.813 m/s² Istanbul 9.808 m/s² Paris 9.809 m/s² Athens 9.807 m/s² Havana 9.788 m/s² Rio de Janeiro 9.788 m/s² Auckland, NZ 9.799 m/s² Helsinki 9.819 m/s² Rome 9.803 m/s² BangkoK 9.783 m/s² Kuwait 9.793 m/s² San Francisco 9.800 m/s² Brussels 9.811 m/s² Lisbon 9.801 m/s² Singapore 9.781 m/s² Buenos Aires 9.797 m/s² London 9.812 m/s² Stockholm 9.818 m/s² Calcutta 9.788 m/s² Los Angeles 9.796 m/s² Sydney 9.797 m/s² Cape Town 9.796 m/s² Madrid 9.800 m/s² Taipei 9.790 m/s² Chicago 9.803 m/s² Manila 9.784 m/s² Tokyo 9.798 m/s² Copenhagen 9.815 m/s² Mexico City 9.779 m/s² Vancouver, BC 9.809 m/s² Nicosia 9.797 m/s² New York 9.802 m/s² Washington, DC 9.801 m/s² Jakarta 9.781 m/s² Oslo 9.819 m/s² Wellington, NZ 9.803 m/s² Frankfurt 9.810 m/s² Ottawa 9.806 m/s² Zurich 9.807 m/s² AquaBAT User Guide V1.04 * Page 24 Transient Protection Why use Fibre Optic communications on buried sensors Immunity to Microwave and RF radiation Safe from lightning strikes by design Corrosion proof design - Faraday cage Protection No signal degradation with time No electrical earth problems Fast Installation - No need to hide cabling to protect communications and power supply. Simple Fibre Cable Installation - Only hex key and scissors required. AquaBAT The AquaBAT water level logger has advantages over any other similar devices or sensor deployed using traditional copper wire for power supply and communications operations. The advantages for using fibre optic plastic cable are: Iso-voltage Levels 100 KV steps Theory of Operation Fibre Optic Cable The drawing above shows the effect lightning hitting a structure which is used to host instruments deployed underground, or fitted into large structures using traditional wire based communications and power supply arrangements. Sensors deployed across a copper wire based network with external power supply, can all be damaged by lightening or the results made unusable by noise created by electromagnetic interference. Interference is often caused by mains pickup or ignition noise from engines. When long runs of copper cable are deployed they act as an antenna making the cable very susceptible to this type of interference Case forms Faraday Cage Why use Fibre Optic Communications Faraday Cage The enclosure surrounding the AquaBAT instrument consists of a single solid piece construction body that when completed with the top clinch plate forms a full conductive path around the instrument. Any local potentiometric effects caused by lighting strikes appears as the same voltage level around the instrument and there is no chance for break down as there is no potential difference. There is little chance for damage to the instrument and no chance for break-down of the fibre optic cable. Fibre Optic Cable The concentric lines shown in the above fibre represent Iso-voltage levels at the instance of the lightening strike. Each individual line represents a potential difference of 100 KV. A cable that connects the instrument at the top of the bore hole to the sensor at the bottom can in effect cross multiple iso-voltage lines and so cause high voltages to appear across the cable and sensor. These high voltages can break down the cable isolation and destroy the sensor. Copper cable also acts as a antenna and can very easily pick up local electromagnetic interference and is a particularly difficult problem to solve especially in long cable runs. There can be no electro-magnetic pickup when using fibre optic cable. Header Unit How to prevent damage AquaBAT Keynes controls prevent damage to the AquaBAT units by using a solid fibre optic plastic cable for communication and deployment. Plastic fibre does not conduct electricity even if it takes a direct hit from lightening and therefore it can never damage the logger unit. AquaBAT unit deployment using Fibre Optic Cable and shows the instrument electrically isolated at a single electrical potential level AquaBAT User Guide V1.04 Page 25