Download here. IBC Manual v0.1

Transcript

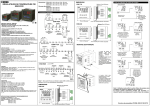

Integrated ‘Bot Controller (IBC) User Manual Revision v0.1 – May 2003 www.robowars.org As they say in all the product manuals, “Congratulations on your purchase of the Integrated Bot Controller from RoboWars”. We hope you like it. We designed it for our own use first, and then decided to offer it for sale, so you can be assured we engineered it to be the best possible controller for its intended application. The IBC is designed to convert the servo-motor control signal from standard hobby radio control receivers into a high-current PWM drive suitable for controlling the speed and power of small permanent magnet brush motors. It’s on board microprocessor includes failsafe and auxiliary-relay control functions, and the wide-range switching voltage regulator makes it able to operate off nearly any combination of batteries from 4v to 36v. Connecting and using the IBC is very simple thanks to its integrated compact design. 3. R/C Servo Input Leads 1. Motors Left & Right 4. Auxiliary Connector (Optional) 2. Power Input 5. Option Jumpers (Layout below is rotated 180 degrees from above photo) • 1 - Motor Drive Leads. – H1a/H1b and H2a/H2b. These are the outputs that connect to your motors. The IBC is provided with short lengths of 12 gauge wire pre-soldered to these points for you to attach to. We suggest securing all pre-attached wires to screw-down ring-type terminal blocks that are mounted on the enclosure you use for the IBC. The main wires to your motors can then be attached to the other side of the terminal blocks, making installation and removal simple and reliable. H1a and H1b should be attached to the two power terminals of one sides drive motor, and H2a and H2b should be attached to your other side motor. They are not polarized and can be attached either way around. The correct orientation will vary depending on which side of the robot your motor is on and its gear reduction method. The left and right motors are usually connected in opposite directions to each other. If the motor runs backwards to the desired direction, reverse the connections to it. Multiple motors can be attached in series or parallel provided the maximum combined voltages and currents do not overload the controller. • 2 – Power Input wires. – B+ and Ground. These are the main power input to controller. Connect to your motor drive battery (after any isolation switches). Power for both motors is drawn through these wires, so ensure a good connection is made to allow high current flow. Short Lengths of 12 Gauge wire are pre-soldered to these points. Red is positive and can be used with voltages from 4v to 36v. Black is negative and should be connected as directly as possible to the batteries negative terminal. We do not recommend earthing via the Robots frame. The power input is protected against accidental brief reverse-polarity connections with an on-board diode, but please take care to get these the right way around. • 3 – R/C servo Input Leads – Left, Right and Aux1 These 3-wire leads attach to your radio control receiver. They have standard connectors that will fit most hobby radio control receivers. The connectors are wired to suit Futaba, JR and Hi-Tec receivers; if you have an Airtronics or other brand radio receiver, please check its servo pin outs before connection. The brown wire is Ground (-), the Red Wire is Positive (+V) and the Orange wire is Signal. If you intend to use the controller’s on-board “Mixing” feature, make sure the left and right inputs are connected to the receiver outputs that correspond to the X and Y axis of the single transmitter joystick you wish to use for driving. The Aux input can be connected to any other desired receiver channel or left unused. Power can be supplied to the receiver from the controller through these leads if the “BEC” jumper is connected (see below) • 4. Auxiliary Connector – AUX1 OUT rd This connector provides the 3 channel (Aux1) trigger outputs which can be used to operate relays for weapon control or other functions, as well as the FLIP input and low-current 5v and 12v supplies. Pin details are as follows. Pin 1 is the end of the connector that is closest to the servo-input leads #1 = +12v – This pin will provide a stable 12v output from the switch-mode regulator, regardless of the battery input voltage. Do not attach devices that use more than 300ma. Small relays and remote-power LED’s (with a suitable resistor) can be powered from here. #2 = AUX High – An “Open Collector to Ground” output that will activate [internally connect to ground (-)] when the “AUX1” Servo input Joystick is more than 30% “Forward”. This output can be used to ground one side of a relay-coil to trigger weapons. The maximum current is 300ma. Use an intermediate relay if you require more current than this. #3 = AUX Low – The same as AUX High, but activates when the AUX1 input is more than 30% “backwards” #4 = +5v – This pin provides a regulated 5v output from the onboard 5v regulator, regardless of battery voltage. Do not attach hi-current devices to this pin. Suitable for small relays or LED’s (with a suitable resistor) only. #5 = FLIP Input – an input that tells the controller to reverse its direction and steering controls if the robot is turned upside down. This can either be connected to a tilt-switch that grounds the input when the bot is inverted, or to either of the AUX High or Aux Low outputs for remote control of the flip rd function from the radio transmitter (if the 3 channel is not required for weapons). Do not exceed 5v on this input. FLIP is active when grounded (0v). #6 = Ground (Gnd) – Earth return point and ground reference for the Aux and FLIP inputs and Outputs. This should be used for any auxiliary connections rather than relying on the main power earth, since heavy current surges through the main cables can cause voltage fluctuations on the main earth point. • 5. Option Jumpers – DB, M, B and BEC. These pins set the operation options for the IBC and can be either left “open” (jumper removed) or “closed” (jumper connected) using the same sort of jumpers as used in personal computers. Their functions are as follows. DB = “DeadBand” – Closed = normal DeadBand, Open = wide DeadBand - This jumper alters the “width” of the center-off area of the joystick inputs. If the center-play in your radio’s joysticks causes the motors to move slightly even when the control joysticks are centred, then select the wide-DeadBand option by removing the DB jumper. This will decrease the sensitivity of the robot to small stick movements around the center position. M = “Mix” – Closed = Mixing On, Open = Mixing Off (Tank steer). This jumper tells the controller to combine (Mix) the left and right servo inputs so that a single joystick can be used to control both left and right motors simultaneously. This style of control is much easier than the older “Tank Style” control, where the left and right motors are controlled by separate joysticks, requiring two-handed operation. If Tank-steering or transmitter-based mixing is desired, remove this jumper. B = “Braking” – Closed = Braking on, Open = Braking off. This jumper causes the controller to apply active current recirculation to the motors by connecting their outputs together when the joystick is returned to the center position. This causes the robot to come to a halt much faster when the controls are released and usually offers superior steering and control. If braking is not desired, remove this jumper and the motors will “Coast” to a stop when the stick is centred. BEC = “Battery Eliminator Circuit”. Closed = BEC On, Open = BEC Off. This connects the on-board 5v regulated power to the positive pin of the servo-attachment leads, which supplies power to your radio receiver from the controller, “eliminating” the need for separate receiver battery. This prevents flatreceiver batteries and saves weight and space in small robots. Do not connect a battery to the receiver AND turn on the BEC circuit since they may have different voltages. Do not use the BEC function if you are also going to run Servo-motors from your receiver, since they use more current than the BEC can supply. • 6. Failsafe Function The controller has an inbuilt failsafe function that will disable all outputs if no radio signal or an invalid radio signal is received on the inputs. This is essential to pass safety inspections for combat robot events, not to mention your own safety. Some older or cheaper radio controls however do not comply with the standard servo-control specification, and may produce an over-range signal at maximum joystick-travel. This can cause false failsafe triggering, and is apparent when the ‘bot works normally at part throttle, but suddenly stops when the stick nears or reaches full travel. Most radio’s have adjustable “Travel”, “Span” “ATV” or “Endpoint” settings to correct this. If yours does not, then either install joystick travel-limiting stops on your radio transmitter or take your radio to a hobby-shop for adjustment to the correct maximum travel (1uS-2uS signal) • 7. Current Capacity The IBC uses IRF1405 Mosfets that are theoretically rated for over 75 Amps of continuous current. In practice however, this is limited by the ability of the FET’s to dispose of heat. The IBC’s solid-mass heatsinks allow the FET’s to handle large surges of current without damage, but the continuous power rating will vary according to the cooling airflow available to the heatsink. For maximum current handling applications, a fan should be provided to ensure sufficient cooling, but this should not be required for the typical application of this controller (12Kg or lighter robots). For comparison purposes, other controller manufacturers rate un-heatsinked, fan-cooled FETS at 40 amps, and 50 Amps for heatsinked, fan-cooled FET’s. If in doubt of your motors average power use, check the heatsink temperature after use. If it is uncomfortably hot to touch, a fan is recommended. • 8. Disclaimer The IBC controller has been designed for experimental use in hobby-robots. Its performance is not guaranteed for any particular application. Responsibility for determining its suitability for a motor or robot lies solely with the end-user. Use of this controller is at the owner’s risk. It must not be used in any situation where its failure may cause a health or life-threatening situation. It should be understood that use in any combat robot will subject the controller to unknown conditions (overloads, short circuits, misuse, shocks, vibration and physical damage) beyond the designer’s control, and hence any failure of the controller that is determined by Robowars to be due to such external factors, and not a result of a production fault or defect will not be covered under any express or implied warrantee. Repair, replacement and shipping of controllers deemed to be damaged in this way will be entirely at the owners’ expense. Combat Robots are dangerous. *You* are responsible for all actions performed by your robot, whether it is under your control or not. • • 9. Specifications and Features • Two x 50 Amp capable Heatsinked MOSFET Motor Drive Channels • TWO x Auxiliary Open-Collector Relay Outputs for weapon control – 300mA Drive Current each • FLIP input that reverses the steering controls if your bot is inverted – Switch to ground to activate • LOW VOLTAGE switching regulator - runs off any voltage from 4v - 36v • Built-in FAILSAFE function. Pass any Radio control safety test first time. 1uS – 2uS valid range • Built in MIX Function. No more Tank-Steering. One joystick drives AND turns • Built in BRAKE function. Precise steering control using active current-recirculation-techniques. • Built in BATTERY ELIMINATOR Circuit. – Powers your radio receiver automatically from the IBC. 5V output • REVERSE POLARITY PROTECTED. Inline diode protects the circuitry from expensive mistakes. • BATTLE PROVEN DESIGN. OSMC-based Mosfet drive circuitry and Software code • AUSTRALIAN DESIGNED AND MADE - Maximum value for money • FULLY OPEN SOURCE - No "Secret" circuit diagrams or "confidential" code • ALL IN ONE DESIGN - Simple to connect and use. • COMPACT SIZE - Just 130mm wide x 55mm High x 30mm thick. • LIGHTWEIGHT – Just 188 Grams with pre-installed 12 Gauge cables and servo leads • 4oz THICK COPPER PCB – capable of handling hi current flows • Includes all connectors and pre-attached wires necessary for immediate use 10. PCB Layout & Tracks D +5V Option Select / Program Header U2 2 DeadBand1 4 3 JP6 6 5 8 --Mix-- 7 10 -Brake- 9 +5V 1 RST 1 2 1 C4 .1uF +5V RESET Y1 12Mhz XTAL1 XTAL2 RESET U1 R12 10K 1 4 5 20 10 (SCK) PB7 (MISO) PB6 (MOSI) PB5 PB4 PB3 PB2 (AIN1) PB1 (AIN0) PB0 AT90S1200P PD6 +5V PD5 (T0) PD4 GND PD3 (INT0) PD2 PD1 PD0 AT90S1200P 19 18 17 16 15 14 13 12 11 9 8 7 6 3 2 MOSI SCK MISO 2 SCK MISO MOSI PB4 PB3 PB2 PB1 PB0 PD6 PD5 PD4 PD3 PD2 PD1 PD0 PD6 PD4 R13 1K 1K 1K 1K R16 1K 1K R14 R15 PB1 R17 R18 PD2 PD3 PD0 PD1 2 +12v R34 14K BHI1 AHI1 DIS1 BLI1 ALI1 BLI2 ALI2 DIS2 BHI2 AHI2 R30 R31 R32 10K 10K 10K +12v R33 14K +12V R27 R28 R29 10K 10K 10K +5V 3 6 3 +12v R35 249K D11 UF1002 D13 UF1002 BHI1 AHI1 AHI2 BHI2 UF1002 R36 249K +12V D12 +12v R37 249K 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 C8 BHO BHS BLO BLS VDD VCC ALS ALO AHS AHO 1uF 50v U3 C9 BHB BHI DI5 VSS BLI ALI AHI HDEL LDEL AHB 1 uF 50v C10 BHO BHS BLO BLS VDD VCC ALS ALO AHS AHO 1uF 50v U4 C11 BHB BHI DI5 VSS BLI ALI AHI HDEL LDEL AHB 1 uF 50v BATT+ +12V AUX HIGH AUX LOW +5V FLIP C1 GND 4700uF 50v AUX1 OUT 1 2 3 4 5 6 UF1002 GND +5V R38 249K +12V D14 R24 10K 20 19 18 17 16 15 14 13 12 11 20 19 18 17 16 15 14 13 12 11 H11 TD5 D15 DIODE BL01 BH01 AL01 AH01 BL02 BH02 AL02 AH02 4 BHS1 AHS1 BHS2 AHS2 5 +12V C12 .47uF 50v 100uH C13 .47uF 50v +12V L1 2 LT1170HVCT 4 VIN LT1170 VSW FB R20 1K 1uf 50V AH01 AHS1 AL01 AH02 AHS2 AL02 150uF 63v C3 D1 R1 D3 R3 D1-2 R1-2 D3-2 R3-2 D9 MBR350 Q1 Q3 Q1-2 Q3-2 5 BATT+ H16 TD2 M-1 H15 M+1 TD1 BATT+ H12 M-2 TD2-2 1 H14 VIN Q2 Q4 Q2-2 Q4-2 Date: File: C Size Title VOUT U8 7812 H13 M+2 TD1-2 C14 5 5.1k - 6.8k if 7812 fitted 470uF 16v R25 VR1 1K R26 620R Integrated Beetle Controller L2 100uH 1 1 MCP130-475DI VDD BEC JP1 LEFT1 10K 1 U5 75477 C2 1.00 1 1 OPTIONS 2 BEC R9 PB2 R21 10K S 7 1 3 JP7 2 1 PB0 PD5 R22 10K R23 4 GND RIGHT1 R10 10K R11 10K PB3 PB4 10K 3 3 D2 R2 D4 R4 D2-2 R2-2 D4-2 R4-2 +12V 1 VIN U6 7805 BH01 BHS1 BL01 BH02 BHS2 BL02 VOUT 3 v1.01s C6 47uF +5V 6 R19 220R C7 .1uF 6 Revision D10 LED D C B A 26-May-2003 Sheet of C:\Documents and Settings\Brett\My Documents\BattleBots\OSMC\Our Drawn By: Version\IBC\IBC1.ddb Number Integrated Bot Controller - I-B-C - OSMC-Es copyright 2002 - www.robowars.org C15 1uf 50V GND 2 5 CLAMP 1 2 3 JP8 2 1 AUX1 3 JP9 2 1 2 VC 1 GND 3 8 VCC C B A 1 GND 4 VSS 3