Download Body & Trim

Transcript

I.:",

CONTENTS

GENERAL SERVICING .. , '

""." .. ,2

2

Precautions,

Supplemenlal Restraint Syslem (SRS) "AIR

BAG" and "SEAT BELT PRE-TENSIONER",

2

,3

Clip and Fastener.

BODY END ..

Body Fronl End

Body Rear End and Opener,

DOOR

Door Glass Fitting Adjustment.,

INSTRUMENT PANEL

INTERIOR TRIM,

6

6

,8

,,10

, .. 11

, , 14

EXTERIOR TRIM

* For seal belt. refer to MA and RS sections.

17

,22

* For body eleclrical systems, refer to EL section.

SEAT

Front Seat..,

Rear Seal,.,

SUN ROOF .. , .. "." ..... " ...

WINDSHIELD AND WINDOWS

Windshield and Rear Window

Side Window,

DOOR MIRROR.,

..

FRONT AND REAR AIR SPOILER

Front Air Spoiler

Rear Air Spoiler

BODY ALIGNMENT

Engine Comparlmenl

Underbody

27

27

',1

30

31

35

35

36

... 37

38

,38

38

39

39

41

'..'1"1

;','r

:

1\

GENERAL SERVICING

Precautions

•

•

•

•

•

When removing or installing various parts, place a cloth or padding onto the vehicle body 10 prevent

scratches.

Handle trim. molding, instruments. grille, elc carefully during removing or installation 8e careful

not to soH or damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound. be careful that the sealing compound does not protrude from

parts.

When replacing any metal parts (for example body outer panel. members, elc.), be sure to take rust

prevention measu res.

Supplemental Restraint System (SRS) "AIR

BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System" Air 8ag" and "Seal Bell Pre·tensioner". used along with a seat

belt. help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The Supplemental Restraint System consists of air bag modules (located in the center of the steering

wheel and on the instrument panel on the passenger side), seat belt pre-tensioners. a diagnosis sensor unit, warning lamp, wiring harness and sprral cable Information necessary to service the system

safely is included in the RS section of this Service Manual.

WARNING:

•

To avoid rendering the SRS Inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inllal/on, all maintenance must be performed

by an authorized NISSAN dealer,

•

Improper maintenance, Including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system.

•

All SRS air bag electrical wiring harnesses and connectors are covered with yellow outer insulalion. Do not use electrical test equipment on any circuit related to the SAS.

BT-2

GENERAL SERVICING

Clip and Fastener

•

•

Clips and fasteners in BT section correspond to the following numbers and symbols

Replace any Clips and/or fasteners which are damaged during removal or installation

Symbol

Shapes

No

@i)

fJ

Removal &. Inslallation

T i cv

Removal:

Remove by bend Lng up with

f1al -bladed screwdrivers or

clip remover

f~r'

SBF302H

SBF:l61B ....

~-,

®

9

~

lfwT~' ~

'--

Removel:

R"mOV9 Wlth a clJp remover.

r---

SBFJOJH

@.D

K

fOi

@)

u

11

i

i?

,

~

S8F423H

Push

e

C:J

...

Push center pin to /

calchlng position.

(Do '101 remove

center pin by hilling 11.)

lr: T...

Push

.0.

Installation,

SBF1C11lE

SBF25BG

Removel:

11

BT-3

r~'

Clip

FInisher

""SFSISB

SBF636C

GENERAL SERVICING

Clip and Fastener (Cont'd)

Symbol

Removal & Installation

Shapes

No.

MBFS1911

MBf520e

RemDval:

SBF10dB

Remove1;

Type 1

C1l Then oeM up

.. (;t.~~~~

il"

Push

Type2

SBf653B

SBF9\4B

Removel:

Holder porhon of clip must be

~pread oul to remOve rod

SBf7668

BT-4

SAF7708

GENERAL SERVICING

Clip and Fastener (Cont'd)

Symbol

Shapes

Removal & Inslallation

No

Removal,

1, Screw out with a Phillips

<@i)

i

@

i f

~~r 8fp

~ 1

~

~/

~

SBF076B

2

screwdriver.

Remove temale

portion wIth (,

flal·bladed

screwdriver [ ___~

J

n

i

I

~.

SBF992G

~

l·

C

L-

,.1

",'1"f

, I'

'I

BT-S

BODY END

Body Front End

•

•

•

•

•

When removing or Inslal'ing hood, place a clOlh or other padding on hood. This prevents \/ellicle bOdy

rr om being scratched

Bumper fascia is made 01 plastic. Do not use excessive force and be sure to keep oil away from iI.

Hood ad: ustrnent Adj ust at hmge portion.

Hood lock adiustment: After adjusting. check hood lock control operation Apply a co.:!t (If grease to

hood locks engaging mecllanisnl.

Hood opener: 00 not attempt to bend cable iorcibly. Doing so 'lncreases ellart require(1 10 unlock

hood.

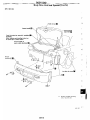

REMOVAL -

ill

('£1

@

@

®

®

(f)

®

®

@)

@

Front bumper assembly

Remove DOlts securing bumper li:1scia to engine undercover.

Remove screws and clips ~ securing left and right sides of front fender protector Then remove

the front fender pr()lectof.

Remove clips @ill) securing Iront grrlle, then remove the front grrlle.

Remove clip ~ securing bumper fascia bracket to hood lock stay

Remove screws located at wheel opening.

Remove the screw securing each side of fronl cle>arance lamp Dsscmbly. then remove the front

clearance lamp assembly.

Remove the screw securing each side of front turn signal lamp assembly. Then remove the fron~ turn

signal lamp assemb:y.

Remove bolts securing each side of front fender bracket.

Remove nuts securing left and right Iront fenders to bumper fascia bracket

Remove nuts and bolls securing bumper assembly to fronl side member.

Extract bumper assembly,

Remove bolls securing bumper fascia bracket to bumper fascia.

m

m.

@

@ Disassemble bumper tascia and bumper fascia brack.et

BT-6

j

se

c.

.....

•

,~

MO~!S:~~\

,at hood

Adjust

mesl,e,., .1 a

0059

• ,otter

When

10 \ 5

-

sec\J'lT1~ ~ood

Ie

'

onl d)

C

m,... (003Q to

arJj\Js\rre(\(, ad usl 0

c

urnper

\

not till SInker "'us, 00(.1<, ertSLJre

• ~7t:'rHa;'

ronl End

pnmary 10 k

\

~~D~~:rl<po,,""'''

man lender.

ruboer

•

Body F

250.'61.25' '6

••" ,

• 3.6,..6".630.6"'.147

II

does

l"'''\"'~ 1~~~'!lOn"'d at lhe

o~.'ale

IBtc~

1'1000

and ,.e~~,,~me,,' enSur. thai h(}()ll

'

r1 primary

Hood lock

ary locI<

seconaary

pr1>pe1..y.,gll>

hOoid"1l

l

r· ~o:.:"",

or. th.n 5.0 n1m {O.H1 In}

t~:ent

8umpef ",11M' ad

•

Adjust so thai

\er>d..., <\t that '1m IS ahgnell with

appro. 2 m

e deflection i

'<JOb "' (008 in)

5

t:l mm (0 51 ,~;, ;ree neigh' IS approt,

IElum~(

I~{~"

<II

~

BT-?

Bumper

N.no (kg.",samb'

II Ibr rrlCunllng bolls,

m

"ul~ a~d

clIps

BODY END

Body Rear End and Opener

•

•

•

•

•

When removi ng or install ing trunk Iid, place a cloth or o~her padding on trunk lid _ Th is prevents

vehicle body from being scratched

Trunk lid adjustment: Adjust at hinae-trunk lid portion for proper :runk. liJ fit.

Trunk lid lock system adjustment: Adjust stnker 50 that it is In the center of the lock After adjustment.

check trunk lid lock operation.

Opener r.able· do not attempt to bend cable L'sirlQ e~ceSSI\ie force

After installation, make sure that trunk lid and fuel filler lid open smoothly.

REMOVAL -

Rear bumper assembly

G) Remove

® Remove

@ Remove

@) Remove

® Working

trunk trim. Refer to "TRUNK ROOM TRIM" in "INTERIOR TRIM" for details. (BT-21)

clips csm securing rear panel upper to bumper fascia_

clips CS101 securing rear panel lower to bumper fascia_

bOlts from lower side of each side bumper

inside trunk, remove nuts securing left and right rear fenders to bumper fascia [i1

(§) Extract bumper assembly II) .

----_._------

\~~

\~/J :;;

L

Fuei ',lIer t'd

apul\er & control

(OJ

BT-8

N·m (kg-m. f1-lbl

BODY END

Body R ear End and 0 pener (Cont':i\d)---- .SEC. 843-850

i.L

8T-9

•

•

For removal of door trim. refer to "DOOR TRIM" in "INTERIOR TRIM" lor details (BT-19)

After adjusting door or door lock. check door lock operalJon.

SEC. 800·803.805

r

Door g'.tu -topper

adjullmen!

I

l

Door

II'." slIb-channa' adlulIlmBnl

:- I~~

~

L

t

~/~13-16

~-t

~

(1.3 ·1.6, !I. 12\

~-,

"' 'Z

L

~

I

I~.-Door

~t6 .dlulIllNnl

~ .:~:u ·28

(2.1 ·2.9,15 - 21)

i(OJ1t. --'~

1l~

15

(1

t • 1.5, 8 -

____J

BT-10

_

(1.8 • 2.4. lJ· 17)

~ N-m (kg'" It·lbl

---------.-J

.l;IJ.

__

r~~~

-_/~~

Striker adlustment

~\\

~:.,'1

~~~18.2..

..::::=rr~)

I

HI" ••...., ••

Door Glass Fitting Adjustment

The door glass is properly adjusted using the following five

methods:

In-oul adjustment (at the glass waiSI)

[;] Fore-aft tilt adjustment

[!J In-out tilt adjustment (at the glass Upper slop)

1!1 Up-stop adjustment

Fore-all adjustment

NOTICE:

When adjusting the door glass, it is nol necessary to remove

the outside door molding.

m

m

~1':Vl

Adjustm_ent locations

Front

L

Adjustment standard clearance

SEC. 803

t - 5 (0.04 . 0.20)

Weatherstrip

Afttalner hoiller

A

Front

o - 3.5

Secllon A -

(0.• 0.138)

A

=::=:j

~. Side window molding

-

Glass

Una. mm (in)

, --t-;5. 1.5 {O.1n • 0.2'95)

Sec110n B -

~

B

SflfJ94HA

..

- ~ ~ _ _----~------

8T-11

I

8..

DOOR

Door Glass Fitting Adjustment (Cont'd)

m IN-OUT ADJUSTMENT (at the glass waist)

Outside moldmg with

outer stabilizer

1.

Raise door glass until glass stopper is in contact with inner

stabilizer, just before the window stops.

2. Loosen adjusting bolts

3. Lightly press door glass upper end outward so that glass

outer surface contacts outer stabilizer. With glass held in

that position, press inner stabilizer to glass inner surface

and tighten adjusting bolt.

CAUTION:

Make sure nap portions of stabilizers are clean and free from

011. grease, elc.

Dutstae

@) FORE-AFT TILT ADJUSTMENT

rm-;:nt

•

1- ¢::JrhV'OdY';d'

/L~W".""'"

r.~

~

Adjust door glass sub-channel so thal the adjustment standard clearances A - A and B - B (Refer to BT-11) are

obtained at the glass and retainer holder/body side weatherstrip locations.

Door glass

sub-channel

MBF500B

r~u 2:J

R~

~<}

Upward

Door 111118& aub--chllnnlll

~

I

[!J

¢:' Correct

•

For sub-channel adjustment procedures, refer to figure at

left as a guide

CAUTION:

•

Make sure door glass sub~channel is horizontal.

• The fore-aft tilt adjustment musl be made at the same time

the fore-aft adjustment II Is made.

Downward

~

.&

¢' Incorrect

MBF501B

l!I

IN-OUT TILT ADJUSTMENT (at glass upper stop)

1.

Adjust door glass-Ie-holder clearance to 0 to 3.5 mm (010

0,138 in) (A) with the adjusting bolts

CAUTION:

•

Turn adjusting bolt clockwise 10 move door glass upper

end outward,

•

Turn adjusting boll counterclockwise to move door glass

upper end Inward.

•

For sub-channel adjustment procedures, refer to figure at

left as a guide

CAUTION:

•

Make sure door glass sub-channel is horizonlal.

• The fore-aft lill adjustment must be made at the same time

the fore-aft adjustment ~ is made.

BT-12

Door Glass Fitting Adjustment (Cont'd)

I!J

UP·STOP ADJUSTMENT

1

Adjust panel stopper height so that clearance at upper

edge of door meels the adjustment standard clearance

A - A (Refer to BT-ll). Make sure front and rear glass @/

stoppers lightly contact front and rear panel stoppers. then

tIghten adjusting nuts.

If stoppers do not contact each other, adjust sub-channel

nut. Refer to "fi] Fore-aft tilt adjustment",

Open and close doors to make sure upper end of door

glass does nol contact holder.

lower panel side

slopper [Upper

end of door glass

moves downward I

I

2.

Adjusting nut /

3

Glass s,de

stopper

(Front. Rear)

~

[;J FORE-AFT ADJUSTMENT

Fronl~

<:: ,./\,'

~

QRear

3

55.

loosen

Jock nuts

then adjust.

~

Gu><le (ail

L.----______

MBF!;04B

Adjust guide rail in lhe fore-aft direction so thai when door

is closed or opened the clearance between upper edge of ~(G

door glass and holder conforms to the .adjustment standard clearance A - A (Refer to 8T-11).

2 If ouler perimeter of door glass interleres with holder when Fia

door is opened or closed, refer to "Ii) Fore-an tilt

adjustment" for procedures.

CAUTION:

When loosening guide rail lock nut, prevent adJusllng bolt

from turning by holding It with a standard screwdriver.

3.

Lower the glass slightly until the glass side stopper comes

off the panel side stopper.

CAUTION:

Do not lower the glass excessively.

~ 1lI~CoN.O'' '!

Glass s,de stopper

After completing door glass adjustment, rellghten all lock

nutS.

CAUTION:

While lightening lock nuts, hold adjusting bolts using a standard screwdriver to prevent them from turning.

•

flat -bladed

...

" ~""~

~~~'(,

M8FOIlO.l\

BT-13

INSTRUMENT PANEL

CAUTION:

•

Disconnect ground terminal from battery in advance.

•

Disconnect air bag system line in advance.

•

Never tamper with or fOfce air bag lid open, as this may adversely affect ai, bag performance.

•

Be careful not to scratch pad and other parIs.

REMOVAL -

Instrument panel assembly

I

Audo &

A/CCO~

Remove air bag module (driver] and steenng wheel Rerer to "' SlJPPI F.

MtN" A\. RESTRAINT S'iSTEM"' In AS secl,on lor de\~lls

(D SIl?~Tln9

J

-------------'---------

column cover and comlJlnalloll sWlIcn

• AemOlle scr(!W$

'----~-_-_-----TI-------------~--

@

I~

1

A,'T iinisher or MiT shiH

In.l,um,,,,' low,,'

side

•

~r

\~er bools

m

On drive'

Remove screws

I'@ Instrumen! lower reinforcement

1_ •

<ID

I

Remove

bol'"

Cluster lid A

• Remoll'! screws :hen disconnect harness conneclors

~~ ~nTlbH'\al.. t:<n mmQf

• Remove .crews then disconnect harness conr>eclors

r----

o

T

- - .- - - - . " - - - . _ - - - -

Ceol@r ve,,"ilat;orl assemblt

• P,J II oul wah a r1al·l>laded sc' ewdflver_

~oo

--~~

-- -----==c

(!'i Ale or healer conlrol

• Rp,movp. ,,-:rf'wc;.

---r-l~--~~-

I

®

Glo~e bo~ ~;sombly

• Hemove serews

BT-14

I

Glove box

SEC. 241l.487·680·685·969

~[!

~~

~~~

l.~

~t

iJ"E

,t11jn

/~'.~!

,~l}

,l'ffi!,

•

ll'sl'umel'll panel

ass~mbty

flIOUrltlnq bolts and nuts

f.l.t~\

pj~

~T

rl~

Mell.' cUp

INSTRUMENT PANEL

MBr52~B

8T-16

INTERIOR TRIM

SiDE AND FLOOR TRIM

CAUTION:

Wrap tl1e tip of f1al·bladed screwdriver with a clolh when removing metal clips from garnishes.

REMOVAl- Body side trim

(f) Remove front and rear seat Refer to "SEAT" tor details (8T-27),

Remove dash side finisher,

®

®

Remove kicking plate.

@ Remove front pillar garnish.

@) I1cmove rear side finisher.

® Remove rear pillar finisher,

®

Remove rear parcol shelf

®

welt. Refer to "TRUNK ROOM TRIM" for details (8T-21)

Remove seat back finishers (Right. Center, Left).

® Remove seat back finisher

BT-11

~,:~1r/~~1J. IJ-~~

<:::>

.-~ J

-r.-.-.-I

Heater un,i

J

~

~

-~--

f-------, _

Carpe

Instrument pan",1

BT-18

-_

DOOR TRIM

REMOVAL - Door trim

[l Remove screws securing inside handle escutcheon, then remove the inside handle escutcheon

m'

®

m.

Remove power window switch

@ Remove screws securing door finisher

@ Remove clips (@ securing door finIsher,

® Pull door finisher to remove clips @) and metal clips [!J from door panel and remove door finisher Disconnect harness connectors,

® Remove ventilator grille and ventilator duct assembly from door finisher I!]

SEC. B09

@ir,

~liI/~,

~11t!l

vc;

'---------------- '-------_._----- '-------------

81-19

TRUNK ROOM TRIM

SEC 799·849

Well

~J

~

8T·21

Mel.1 clip

m

MBF449B

BT-22

EXTERIOR TRIM

rID @

(1) Windshield upper and side molding

I

~

Cowl top grille and hOOd rear

sealing rubber

SEC. 660

Method 1

~;-:v

~\~c,~''''''"•

Appl~

/~~~--

LCOWIIOP~@ /~

.

•

..

<§I>

~J~/~''''

,ulan, to top pOll,on 0/

mold,ng

L

Cut all low~t jlO't,on •

of new mold."~

MBF450B

------.J

...

@.

®

Hood fronl sealing rubber

SEC. 650

F HUlk well 10 gIve it a

good i!lppearanc.e

Method 2

1. Cut off sealant at glass end.

2. Clean the side on which panel was mounted.

3. Set molding fastener and apply sealanl to body

'~:. T

panel. and apply primer to molding and body.

- Double·bee<!

lIdhe"Vi! tape

MBfJ5111

4

Install molding by aligning the molding mark

located on center with vehicle center.

Be sure to install tightly so that there is no gap

around the corner.

(~

Body side well

SBF'6\F

Outs,(l~

MBF452B

IG.

BT-23

EXTERIOR TRIM

,..,

I.U

I

@ Body side

.

weath erstnp

. and

atner

SEC. 766

weatherstrip ret .

Retainer

w""

~~o«.m,

\:

Body sIde

weatherstrip

MBf45J8A

BT-24

....

EXTERIOR TRIM

®

Door weatherstrip

@

Before removing door weatherstrip, remove door

trim Refer to "DOOR TRIM" lor details (BT-19).

Rear panel finisher

SEC, 265

SEC. 800

If

L-

MBF4s.tB

® Back window upper and side molding

(SEC. 797)

Basically the same as windshield upper and side

molding

@ Back window lower molding (SEC. 797)

It is mounted with screws,

@ Trunk lid weatherstrip

'

1¢

" / Trunk I'd

,'"wealtlerSlr,p

~O

Butyl

seal

.

MBF456BA

_

@ Sun roof lid weatherstrip

SEC. 736

l:t~l

~

Body panel

MBF<!S7BA

p:o:

EXTERIOR TRIM

@

Rear combination lamp

------------------- ------

,com ~ ",

I

l

I

Heal gun

~~-

~-~---<;'~- (\\\'\ ~~

~~

jllm~\\(LJ

~~~-"-\1~ I \

-----------:::

----

L,.'....

)

~

()l

Butyl seal

II

\

• Wnrm up lamp lISJembly a"'8 to a tempereture n IIttl"

'0

• Apply butyl seol evenly •• II tellds 10 b.. "om~ thin I" th ..

corner._

• Warm up ramp lIllSembly nrea to s temperature a lillie

below 60"C (HOOF).

,'wo.

MGf459B

@ High-mounted stop lamp

81-26

.

carefully han die it to keep dirt out an d avoid damage.

.

the seat trim.

or installing

.

von

•

When 'emo

9

Front Seal

SEC. 870

,I

L.-=r

t

L_-----~~

BT-27

r:oJ ',(4. .S:~ ..u, 32 - 41)

J

43

Front Seat (Cont'd)

Remove retainer from lower side of seatback with fingers

MBF494B

Roll up seatback trim all the way to gain access to headrest

holder pawls Disengage and push headrest holder pawls to

unlock holder lift off headrest holder.

[-~_-

MBF495B

8T-28

Front Seat (Cont'd)

HEATED SEAT

•

•

•

When handling seat, be extremely careful not to scratch healing unIt

To replace heating unit, seat trim and pad should be separated,

Do not use any organic solvent. such as thinner, benzene. alcohol. gasoline. etc_ to clean trims.

--,'--- ,---,---'--"---/

Se~tback trim ~"d

~~

pad

Trim lemperature

0C (oF)

Increasing 10

DecreaslIlli' 10

35 ' 45

25·35

/95· \131

(77 " 95)

Turns OFF

Turns ON

f-----

Thermos18t operation

(C!L.

ijIT

MBF332B

DiY

* For Wiring Diagram, refer to "HEATED SEAT" In El section.

~m

,r$).

~&:

~I~J

~'jj'

'R1~

BT-29

Rear Seat

SEC. 880

Striker installallon

a

A

Nom (kg.m, 1l·lbl

MBF461 SA

BT-30

SUN ROOF

* For Wiring Diagram, refer 10 "ELECTRIC SUN ROOF" In EL section.

ADJUSTMENT

Inslall motor & limit SW assembly and sunroof rail assembly in the following sequence:

1.

2.

3.

4.

5

6

7.

8

9.

Arrange equal lengths of link and wire assemblies on both sides of sunroof opening.

Connect sunroof connector to sun roof swi tch and positive ( +) power supply.

Set lid assembly to fully closed position

by operating OPEN switch and TILT switch.

Fit outer side of lid assembly to the surface of roof on body outer panel.

Remove motor, and keep OPEN switch pressed until motor pinion gear reaches the end at its rotating range

Install motor.

Check that motor drive gear fits properly in wires.

Press TILT-UP switch to check Iid assembly for normal tilting.

Check sunroof lid assembly for normal operations (tilt-up, lilt-down, open, and close).

m

SBF92QF

81-31

SUN ROOF

•

After any adjustment, check sun roof operation and lid alignment.

•

Handle finisher plate and glass lid with care so not to cause damage_

•

It is desirable tor easy installatIOn to mark each point before removal.

CAUTION:

Always work with a helper.

r

Link and

I aSSembly

w"~=:J

Sh ada

Sun rool trame

as~embly

L,d assembly

assembly

--=r==

~ass I'dup

___------'-

==r=___

~

I

(1) S'oe trim

~

• Rl>mol/e s'de t'lm clIps

------..-J-_ _

- _~-_-====:r=

~-sun

'001 11<1 mour.1 nvls

==r==----~

----

l~emb\Y

=r=

I ~)

Aaa! dram moun! screws

[,~

Reay d/ain

-==r=

-----r==--------=r

assen\~ly

~~e sun rool switch to 1"1 glass lid down

i IID

==r=

~

~

:=r:::=-------,

--==::L

~_=r==

-----=r:=

I

..::::::r=

====:I

t

~

I

_ _------'1

Shade assembly

_

]

==r=

I

_

m

Sun ,oat switch/,nl""", accessories/headlining

• ReIer to "ROOF TRIM \IH-20)_

===r:

I

(7)

MOlor sw,tch

~

b'ac~el

--=r:::::==

I~

--==::L

_

Molor assembly

[\ID w,nd~w

-----=c=J om----._----.

dellector hO-ld-e-r

---J------

L!:

I

J

Wmdow deffeeln! moun! sCrew

--J

-~----r--

~

W",dow deHector assembly

J

l: Dra~~s=-=-~

@

[

~:i)

'Rl

!

(15\ GUide

r

'ii) Rear

Sun 'oaf frame assembl)'

-=r=.

]

~

~,nk

I

I

'IO"P~

g~l

~-----.::r

I

I _

==-r=-

,-----c==

'I

I

=r=-

Sun roof un,l b'aLk"il

~----l

and w""

. ;ssemblV

---J

I

1.---------

BT-32

I

SUN ROOF

SEC. 264· 736

1m.

o

t

F'on\

1f

I

.!h-~~

-

~C~ ,~ "J

~,--

-- Gu!de Slopper @

Rea' gUide@

SBTOO)

BT-33

I (1';"

SUN ROOF

m Using flat-bladed screwdriver, pry shade assembly holder

011 rail Then pull shade assembly forward to remove it

from rail

mDisengage pawls trom rail, then remove window deflector holder.

mUsing flat-bladed screwdriver, pry stopper spring off rail

groove. Then slide rear guide backward to remove it from

rail,

mRemove wire and link assembly from rail while pushing

link back with flat-bladed screwdriver,

t.1BF493B

BT-34

REMOVAL

After removing moldings, remove glass.

CAUTION:

Be careful not to scratch glass when removing.

INSTALLATION

•

-I/O

J

, ',\.',

/

\''\\

SBFOJ48

--------

Use genuine Nissan Sealant kit or equivalent. Follow

Instructions furnished wIth It.

After Installation, Ihe vehicle should remain stationary

•

untH Ihe sealant hardens.

WARNING:

Keep heal and open flames away as primers are flammable.

CAUTION:

Advise users not 10 drive the vehicle on rough roads until

sealanl has properly vulcanized.

•

Do not use sealant which Is past its usable term.

•

Do not leave cal1ridge unanended with its cap open.

•

Keep primers and sealant In a cool, dry place. Ideally, they

should be stored in a refrigerator.

•

Molding musl be installed securely so that it IS in position

and lea\les no gap.

~E

Windshield and Rear Window

Inslall dam rubber.

Windshield

1\

1==f~

'

);j

DMh upper panel

8 - 9 (0.31 - 0.35)

~j..©

~j

[

~.~

~,~'II

8. 9

8 - 9

\

(0.31 - 0.35)

Joint portion

Glass

Rear wlndow

61~

f=

(0.31 • 0.35)

@ J o i n t portion

425 (16.73)

'iDS (15.94)

Reef wlndow

B

- 9 • O.JS) ~eh'c1e center

(0.31

8(0.31

. 9 • 0.35)

Tjehicle

8 _ 9cenler

(0.31 - O.35)

Dam rUbber~GlaSS

Double·/aced adheswe tepe-

8 • 9

Body panel

(0.31 - 0.35)

Unit: mm r,nl

Apply sealant 8¥enly.

WIndshield end rear wlndow

Inslall molding lastener.

When installing it. heat body panel and

fastener 10 approx. 3(J to 40°C (86 10 104°FI,

3f ~7

- 8 (0.28 - 0.311

Upper & side molding fasteners

.e

~

vF8SIener

Dam rubber

....

panel~

~

~"

-

)!.:.•>

I-

Glass

:>:::._~

Double·faced adhesive tape

~

MBF4638

.

Unit mm lonl

MBF464B

REPAIRING WATER LEAKS FOR WINDSHIELD AND WINDOWS

Leaks can be repai red WI thoul removing and rei nstall ing glass,

(fti:l

If water is leaking between caulking material and body or glass, determine the extent of leaking. This

can be determined by applving water while pushing glass outward.

To stop the leak, apply primer and then sealant to the leak point.

81-35

WINDSHIELD AND WINDOWS

Side Window

SEC. 830

Seiliant quantity

ill:

12 -

1~

-r--=r---

c-

7 ·8

lQ.26 . 031~ Umt: mm (in)

BT-36

DOOR MIRROR

*For Wiring Diagram. refer to "POWER DOOR MIRROR" In EL section.

CAUTION:

Be careful not to scratch door rearview mirror body.

REMOVAL -

Door mirror

CD

Remove door trim HeIer to "OOOR TRIM" in "INTERIOR TRIM" for details (8T-19)

® Remove inner cover front corner of door fi1 .

@ Disconnect door mirror harness connector.

@ Remove harness clips

t]) Remo\le three bolts securing door mirror, Illen remove door mirror.

SEC. 963

~-==::::=:::=:::--

Remove•

• Wlap nal-hladllo <:J scre....driver "";ltl a cloth to

pr81lent seratchilly ,ea, 0' door mirror. 00 no!

insert screwdriver too tal

91-37

FRONT AND REAR AIR SPOILER

•

•

When installing, make sure that there are not gaps or waves at ends of air spoiler.

Before installing spoiler. clean and remove oil from surface where spoiler will be mounted.

Front Air Spoiler

SEC. 960

Rear Air Spoiler

SEC. 960

\~-

-~

~ lt~~o

,~ ~~

~::

I,

~

~~~~~~J

-- ®

\ (e-Y)

\\...-.-:: ...-:::::--

~

_

V'~"'~~l7

""J~

-Double-faced adhesive tape

BT-38

2

Sealing 'ubbe'

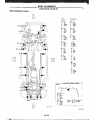

BODY ALIGNMENT

•

•

•

•

•

•

All dimensions indicated in figures are actual ones.

When using a tracking gauge, adjust both pointers to equal length. Check the pointers and gauge

itself to make sure there is no free play.

When a measuring tape is used, check to be sure there is no elongation, twisting or bending.

Measurements should be taken at the center of the mounting holes.

An asterisk C") following the value at the measuring point indicates that the measuring point on the

other side is symmetrically the same value.

The coordinates of the measurement points are the distances measured from the standard line of

"X", "Y" and "z",

z

(+)

Imaginary base line

"Z": Imaginary base line

[200 mm below datum line

("Or at design planl]

C@ : LH

sIde

CffiD : RH side

y

/H

-

:'C. ~,

Front ule center

(0)

Engine Compartment

MEASUREMENT

II

623

Unit: mm

I

L-

MBF376B

._-----.---.--------------

BT-39

BODY ALIGNMENT

Engine Compartment (Cont'd)

MEASUREMENT POINTS

Unit: mm

----

--

o

Front

Radiator core support upper

and side

@ /

~

MBF473B

Radiator core support lower

7 die.

·_-------~--I

o

0

ii:'

8

1_

,H, . .

dl·,l._--L.°_---'--

----...--

_

MBF471 B

BT-40

__ 1--------------

BODY ALIGNMENT

Underbody

MEASUREMENT

...

IG

Q)

E

a:

¢~

jy

.i:

CD

c(

---1

E

~

::)

350

350

®

350

g\~:

~~,

2&3

805

@(~'

@(ci:!

-:- L'

,-

(102)

115

154

104

6)(:3

®C~l

@r§)

Q)

¢~

..

...J

~

_-+----73-1__ (~} §.

255

@(~:'

..

0>

~

....

co

u:

co

u:

M8F375B

BT-41

(-

BODY ALIGNMENT

Underbody (Cont'd)

MEASUREMENT POINTS

Rear

V

Front

coordi nates:

Rear

coordinates:

@,@

@

G ..m·

ID

X : 378

y : --635.5

Z : 214.5

X : 422.5

: 1,650

Z : 103.9

@, (~)

@,@

X : 185.3

X : 564

y

y

: -630

Z : 179

Y

: 1,900

Z : 154

@,(C)

G),CD

X : 370

X : 540

y

y

: -196.5

Z : 254.9

: 2,100

Z : 115.2

@.@

®.®

X : 384.2

Z : 254.9

X : 308

: 2,690

Z : 262.8

@,@

©

y

y

: 32

X : 380

y : 510

Z : 106.2

X : S40

: 2,955

y

Z : 350

®.(D

CD

X : 420

; 1,150

Z : 106.2

X

y

RH side

c)

: soo

y

: 2,955

Z : 350

~

X : 580

y : 3,245

Z : 350

@

X : 530

y : 3,250

Z : 350

Front and rear strut tower centers

I

~-w-,

Coordinates:

®,(PJ

X : 545.1

Y

Z

: 63.6

: 730.9

@.@

X : 479.8

Y : 2,608

Z : 804.6

Front:

Rear:

®. @

@. ®

82.2 dl•.

66 die.

Unit: mm

Front

MBF477BA

BT-42

m

-

HEATER &

AIR CONDllllONER

@f

SECTION

HA ~j2

CONTENTS

1=

.1

MANUAL AND AUTO

L __

TROUBLE DIAGNOSES

-...--J

... 3

PRECAUTIONS AND PREPARATION

Supp Iemental Res tra; nt Syste m (S RS) "A' R

BAG" and "SEAT BELT PRE-TENSIONER" ....... :.... 3

,.. 76

Contents

,

Wiring Diagram -

,

A/C, A -

127

Overview of Control System

Control System Input Components

··

3

COlltrol System Automatic Amplifier (Auto

General Refrigerant Precautions

3

Precautions for Refrigerant Connection

4

amp.}................

Control System Output Components

Precautions for Servicing Compressor

5

Special Service Tools

5

,

6

Precautions for Service Equipment

"

8

DESCRIPTION

Refrigeration Cycle

'

Component Layout..

10

10

,

,

Discharge Air Flow

'-_-------=:1-

"

..

_ _ _~J

DESCRIPTION

Introduction

Features

Control Operation

13

13

'

TROUBLE DIAGNOSES

Contents

Wiring Diagram Wiring Diagram -

12

c=~- ::=J

MANUAL

DESCRiPTION.......

Control Operation

..

,........

14

14

..

HEAT A/C, M _

AUTO

11

37

.45

:===J

[

72

72

.

,

--

72

73

'------_ _-----.J:I

.Ic;t

104

SYSTEM DESCRIPTION

Precautions for Working with HFC-134a (R134a)

HFC-134a (R-134a) Service Tools and

Equipment

76

127

128

...130

130

MANUAL AND AUTO

SERVICE PROCEDURES

"

"'-,

~'r.;

-:;/~".

"

138

138

HFC-134a (R-134a) Service Procedure

Maintenance of lubricant Quantity in

Compressor.........................................

Refrigerant Lines

·

C ompressor M ountlng

Belt Tension

~j

.

140

142

4

14

~~~;

144

Fast Idle Control Device (FICO)

"

144

Compressor - Model DKV-14C (ZEXEL make) .. 145

c---~

l-I~_~~-==:J ~~~~

MANUAL

SERVICE PROCEDURES

..

Overhaul - Push Control Unit Assembly ..

Disassembly

'---------

--JI

--

.

MANUAL AND AUTO

SERVICE DATA AND SPECIFICATIONS (50S).

General Specifications..

Inspection and Adjustment

... 148

148

.148

=:=J

149

..149

149

f{L