Download Parts book for Singer 269W

Transcript

Foriii

1 141

w

1

Re. 2ol)

SINGER

SERVICE MANUAL

Class 269w

I

SINGLE NEEDLE

LOCK STITCH

THE SINGER MANUFACTURING COMPAN

Y

Copyright () 1963 by The Singer Manufacturin

g Company

Copyright Under International Copyright Union

All Rniht Reserved under Inter-American Copyri

ght Union

*A Trodernc,lr ci THE SINGER MANUFACT

URING COMPANY

Printed in U. 5. A.

TABLE OF CONTENTS

DESCRIPTION OF MACI-f INES

OPERATION

ADJUSTMENT

11

12-79

80-841

INSTRUCTIONS FOR ORDERING

PARTS LIST

NUMERICAL LIST

3

3-6

6-10

.

.

iNDEX

—

Accessories

Adjusting Device

Arch Clamp

Arm Shaft

End Play Removal

Barring

Buttonholes

Pockets

Bell Crank

Belt Guard

Belt Loop Tacking

Bell Tension

Bobbin

Removal

Winding

Bobbin Case

Removal

Replacement

Threading

Bobbin Thread Tension

Bobbie Winder,...,,,

.ents

A

Bow Fas..ning

Brake Installation

Brake Lining Care

Button Clamp

Button Sewers

Cam

Timing

Clamp Lifting Mechanism

Cleaning

Clearance under Clamp

Covers

Description of Machines

Driving Arm

Adjustment

End Play Removal (Arm Shaft)

Engaging Arm

Adjustment

Fastening ows

Feed Cam See Cam)

Feed Plate Carrier Bar

Feed Plate Positioning

Flat Bed Work Plate

Gauge 239369

interlocking Arm

Knife Bar

Knife Holder

Knife Thread Holder

Knives

Adjustment

Lateral Rock Shaft

Length of Tack Adjustment

Lifting Arm

58-79

36

12, 40-44, 52, 56

14

8

3

42, 52

46, 50

8, 22, 52

18, 58

3, 56

9

24

4

5

24

4

5

5

6

32

5, 6

3, 42

10

10

34

3, 36-38

3, 38-52,56

8

3, 22

4

3

18, 36

3

20

7

8

28

9

3, 42

,

12, 36, 40, 56

7

3, 54, 79

6, 7

26

16

42

38

18, 42

8

20, 36

7

6

Line Tack

Link Arm Adjustment

Longitudinal Rock Shaft

Lubrication and Cleaning

Machine Pulley

Driving Accessories

Pulley (loose), Packing

hine

Mac

Needle

Setting

Sizes

Needle Bar

Height Setting

Stroke

Needle Bar Crank

Needle Thread Tension,

Oiling

Oscillating Shafts

Recoil Absorbing Mechanism

Sewing Straps

Shoe Tacking

Size of Needles

Shuttle

Timing

Shuttle Driver Adjustment

Space behind Needle

Speed

Split Feet

Starting Lever

Adjustments

Stop Motion, Broke

Installation

Stop Motion Timing

Tacking Adjustments

Tacking Belt Loops

Tension

Regulation

Tension Position Guide

Adjustment

Thread Cutter on Face Plate

Thread Guide

Threading

Thread Retainers

Thread Wiper

Throat Plate

Tripping Mechanism Adjustment

Tripping Points

Timing

Twist of Thread

Uneven Winding, Correction for

“V” Belt Tension Adjustment

Vertical Drive Shaft

Width of Tack Adjustment

20,

3,

74,

3, 4, 36,

48,

3

7

36

4

14

76

4

40,

6G

4

22

6

3

14

6

4

16

9, 26

3, 44

3, 40, 48

4

24, 36

7

/

3

3

44

26

9

26

10

10

7

3, 56

28

6

22, 23

6

3, 18

5, 28

5

5, 28, 36, 42

22, 36, 44,52, 56

.

.

18, 36, 40, 42

8

3, 38.50

10

5

9

7

.3

DESCRIPTION OF MACHINES

Machine 269w8 is designed for barring pockets on

clothing and general barring and tacking opera

tions.

Single needle, lock stitch.

Needle, Catalog 1628 (68x5).

Link take-up. Short bealc, central bobbin, ad

justable oscillating shuttle.

Manually operated thread cutter.

Automatic stop and clutching device.

Two-piece machine pulley (tight) and (loose);

“V” belt groove 2-1/4 inches outside diameter.

Needle bar stroke, 1-9/16 inches.

Clearance under clamp, 5/8 inch.

Space behind needle, 8 inches.

Bor pattern 1/8 to 5/8 inch long and 1/16 to

5/’32 inch wide; consists of 42 stitches (12 stay

ing, 27 covering and 3 tying stitches).

Cylinder bed. Flat bed type work plate fur

nished on request.

Other varieties of Machines of Class 269w are

similar to Machine 269w8, with the following ex

CptionS

-

Machine 269w12 for barring pockets and for other

bar tacking operations.

Bar pattern 1/8 to 5/8 inch long and 1/16 to

5/32 inch wide; consists of 36 stitches (12 staying,

21 covering and 3 tying stitches).

Needle, Catalog 1628 (68x5).

-

Machine 269w14 for tacking shoes.

Tack pattern 1/8 to 5/8 inch long; consists of

21 stitches including 5 overlapping stitches.

Needle, Catalog 3072 (16x100).

.

Machine 269w17 similar to Machine 269w5, ex

cept for cam which produces a tack consisting of

16 stitches (6 parallel, 1 cross-over, 6 parallel and

3 tying stitches).

Needle, Catalog 1627 (68x3).

-

Machine 269w26 for barring pockets on clothing

and other general barring and tacking operations.

Bar pattern 1/8 to 5/8 inch long and 1/16 to

5/32 inch wide; consisting of 28 stitches (8 staying,

17 covering and 3 tying stitches).

Needle, Catalog 1628 (68x5).

-

Machine 269w38 for barring buttonholes in clothing.

Bar pattern 1/8 to 1/4 inch long and 1/16 to

5/32 inch wide; consists of 21 stitches (7 staying,

11 covering and 3 tying stitches).

Regularly fitted with flat bed type work plate

and a clamp for contracting the cut edges of the

buttonholes.

Clearance under clamp, 13/32 inch.

Space behind needle, 7-3/4 inches.

Needle, Catalog 1628 (68x5).

-

Machine 269w5

for stitching 2 or 4 hole buttons

with 21 stitches (18 cross and 3 tying stitches).

Regularly fitted with button clamp for 14 to 50

ligne buttons. If specified on order, machine will

be fitted with clamp for 14 to 50 ligne thin buttons.

Space behind needle, 7 inches.

Needle, Catalog 1627 (68x3).

-

Machine 269w7 for tacking shoes. Tack pattern

1/8 to 3/8 inch long, with 18 stitches (no tying

stitches).

Needle, Catalog 3072 (16x100).

-

Machine 269w9 for barring buttonholes, fastening

bows and other ornaments on shoes and garments.

Bar pattern 1/8 to 5/16 inch long; consists of

21 stitches (7 staying, 11 covering and 3 tying

stitches).

Needle, Catalog 1628 (68x5).

Machine 269w39 for tacking belt loops on trousers,

slacks, sportswear, shirts, etc.

Line tack 1/8 to 1/2 inch long; consists of 28

stitches (including 3 tying stitches).

Regularly fitted with flat bed type work plate.

Needle, Catalog 1628 (68x5).

-

-

Machine 269w11 for general barring and for sew

ing straps on underwear, etc.

Bar pattern 3/8 to 7/8 inch long and 1/16 to

/32 inch wide; consists of 42 stitches (7 staying,

.2 covering and 3 tying stitches).

Needle, Catalog 1628 (68x5).

-

SPEED

The maximum speed recommended for all ma

chines of this Class (except the button sewers) is

2000 R. P. M.

Button sewing Machines 269w5 and 269w17 are

designed to run at a maximum speed of 1850 R.P.M.

The maximum efficient speed for any particular

machine is determined by the material being sewn,

the thread used and the operation performed.

LUBRICATION AND CLEANING

,—

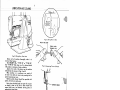

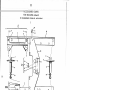

Fig. 3. Oiling Point in Rear

Fig. 2. Oiling Parts, Front View

Clean and oil machine thoroughly when it is

received from factory.

Use SINGERk OIL, “TYPE B” or “TYPE D”.

Use ‘‘TYPE D” OIL when an oil is desired which

will produce a minimum of stain on fabrics.

Apply oil at each of the places on the machine

indicated by the arrows in Figs. 2 and 3.

When machine is in continuous use, apply oil

at least twice daily to insure easy running and to

prevent unnecessary wear.

Machine pulley (loose) should be repacked with

grease, at least once each year.

Using short bristled brush (not point of scissors

or shears), clean out all lint or other waste from

around hook area, and between moving parts on

underside of throat plate.

Close all covers after oiling and cleaning. Wipe

off excess oil from surfaces of machine that may

come in contact with material.

NEEDLES

Use SINGER* needles

Catalog 1627 (68x3), for Machines 269w5

and 269w17.

Catalog 3072 (16x100), for Machines 269w7

and 269w14.

Catalog 1628 (68x5), for all other varieties

of Class 269w Machines.

Size of needle is determined by weight of thread

and type of material being sewn.

-

-

Fig. 4. Determining Twist of Thread

LOOSEN SCREW

LONG

INSERT NEEDLE UP

AS FAR AS POSSIBLE

AND TIGHTEN SCREW

-

THREAD

Use only left twist thread in needle. Either

right or left twist thread can be used in bobbin.

To determine twist, hold thread as shown in

Fig. 4. Then twirl thread over toward you if strands

of thread tighten, thread is left twist; if strands

unwind, thread is right twist.

TO SET THE NEEDLE

Set the needle, as instructed in Fig. 5.

Long groove of needle should face operator,

with eye of needle directly in line with cylinder

bed of machine.

-

Fig. 5. Setting the Needle

RELEASE

LATCH

BOBBIN

2. HOLD LATCH AND

PULL CASE FROM SHUTTLE

DROPS

OUT

Fig. 6.

Removing Bobbin Case

Fig. 7. Removing Bobbi9

TO REMOVE THE BOBBIN

Remove bobbin case and bobbin as instructe.

in Figs. 6 and 7.

.:

5

TO WIND THE BOBBIN

Place bobbin on bobbin winder spindle, as shown

in Fig. 8 and push it up closely against shoulder,

having small pin in shoulder enter slot in bobbin.

Pass the thread from the unwinder through the

threading parts shown in Fig. 8. Wind thread clock.

wise around bobbin a few times.

Push bobbin winder lever to bring bobbin winder

pulley in firm contact with machine driving belt.

See page 6 for adiustment of this contact.

Bobbins can be wound, while machine is stitch

ing.

Bobbin winder will stop automatically when

sufficient thread is wound on bobbin.

If thread does not wind evenly on bobbin, loosen

thread guide screw A, Fig. 8 on tension control at

top of machine and move thread guide forward or

back, as required. Securely retighten screw A.

TO THREAD BOBBIN CASE

Hold bobbin so that thread will unwind on top

from left to right as shown in Fig. 9 and thread

bobbin case as instructed in Figs. 9 toll.

TO REPLACE BOBBIN CASE

Replace bobbin case in shuttle, as instructed in

Fig. 12, making certain that position finger on

bobbin case slips into notch provided for it at top

of shuttle race.

TO THREAD THE MACHINE

Fig. 8. Winding the Bobbin

1. PULL THREAD

INTO SLOT

Pass needle thread from unwinder through thread.

ing points shown in Figs. 13 and 14.

Note: Threading for upper thread retainer used

only on Machines 269w5, 269w9 and 269w17 in place

of thread eyelet, as shown in inset at top of Fig. 13.

Lower thread retainer, shown in Fig. 13, does not

exist on Machines 269w5, 269w9 and 269w17.

UPPER

THREAD RETAINER

FOR 269W5, 269W9

AND 269W17 ONLY

2. DRAW THREAD DOWN

AND UNDER SPRING

4. HOLDING LATCH,

REPLACE BOBBIN CASE

ON STUD’

Fig. 10.

3. TURN BOBBIN CASE

OVER AND DRAW

THREAD UP INTO

POSITION

FINGER

Fig. 11.

5. RELEASE LATCH

PRESS BACK UNTIL LATCH

CATCHES GROOVE IN STUD

Fig. 12.

LOWER THREAD RETAINER

ON ALL MACHINES EXCEPT

269W5, 269W9 AND 269W17

Fig. 13. Threading

the Machine

Draw about two inches of

thread through eye of needle

with which to start sewing.

Fig. 14. Threading

the Needle

()

TO REGULATE THE T[NSIONS

-

_.c

MORE TENSION

B

LESS

I

TENSION

g. 15. RegLilciti nq i

on Needle Thread

a

Si Oil

MORE TENSION

LESS TENSION

—F

Fig. 17. Adjusting Contact of Bobbin Winder

Pulley with Machine Driving Belt.

Fig. 16. Regulating Tension

on Bobbin Thread

T2

2732

Tension on needle thread is regulated by thumb

nut in front of tension discs, as instructed in Fig.15.

Tension on bobbin thread is regulated by screw

on bobbin case tension spring, as instructed in

Fig. 16.

TO ADJUST BOBBIN WINDER PULLEY

Bobbin winder pulley B, Fig. 17 should press

firmly upon machine driving belt C when winding

bobbin. (See instructions on page 5.) To adjust,

engage bobbin winder for winding operation and,

with links D and E in locked position, loosen screw

F. Move pulley, as required and securely retighten

screw F.

7Q4

Fig. 18. Checking Needle Bar Height

(Using Gauge 239369)

TO SET THE NEEDLE BAR

AT THE CORRECT HEIGHT

Turn machine pulley until needle bar

down to its lowest point. With needle bar

positian, needle bar depth-hole K, Fig. 18

be about 27/32 inch above the top surface

throat plate, as shown in Fig. 18.

moves

in this

should

of the

To adjust, loosen needle bar clamping screw

Fig. 19 and move needle bar up or down in connec

tion stud P, as required. Securely retighten screw M.

TO ADJUST THE TENSION POSITION GUIDE

Remove arm side cover plate and loosen pinch

screw G (see inset, Fig. 19) on lifting arm H. Re

move face plate. Raise presser bar until first radius

of tension position guide S2, Fig. 19 touches ten

sion pin. Tighten lifting arm pinch screw G.

E26B7

Fig. 19. Setting Needle Bar at Correct Heighi

7

TO TIME THE SHUTTLE

Turn machine pulley until needle bar moves

down to its lowest point. Loosen pinch screw 350606

in shuttle driver. (See pages 24 and 25).

Insert gauge as shown in Fig. 20, bring shuttle

point against gauge. Then, tighten socket screw in

shuttle driver.

--*

TO ADJUST SHUTTLE DRIVER AND

NEEDLE GUARD

To adjust shuttle in relation to needle, loosen

set screw T2, Fig. 18, and, using two screwdrivers

as wedges, move shuttle race bushing to desired

position. Tighten screw T2.

To adjust needle guard, loosen screw U2, Fig. 21

and move needle guard in or out as required. Tighten

screw U2.

Fig. 20. Timing the Shuttle

(Using Gauge 239369)

TO ADJUST WIDTH OF TACK

(ALONG THE BED)

a

I

F-

1

[

r

Needle Guard Adjustment

.

4

Fig. 22. Adjusting Width of Tack

and Positioning Feed Plate

Ear5eE

S

Fig. 23. Adjusting Length of Tack

To adjust width of tack, loosen nut Q, Fig. 22

(reached through back opening in base of machine).

To make a wider tack (along the bed), slide the nut

over to the right. To make a narrower tack, slide the

nut over to the left. Tighten screw Q.

After adjusting width of tack, it may be neces

sary to adlust position of feed plate in relation to

needle. Loosen socket screw R, Fig. 22 and move

feed plate central with needle. Tighten socket

screw R.

ADJUST LENGTH OF TACK

(ACROSS THE BED)

Remove the cover plate from the base of the

machine, as shown in Fig. 23. Through the opening,

loosen nut S, Fig. 23. To make a longer tack (across

the bed), slide nut S over to right. To make a shorter

tack, slide nut S over to left. Tighten nut S.

After adjusting length of tack, it may be neces

sary to adjust position of feed plate in relation to

needle. Loosen socket pinch screws T, Fig. 22

and V2, Fig. 24 and set feed plate central with

needle. Set driving arm and link arm parallel as

shown in Fig. 23. Tighten screw V2, Fig. 24. At

face plate end of machine, move feed plate to right

so that left end of feed plate slot is 1/8 inch from

needle hole. Tighten screw T, Fig. 22.

Fig. 24. Driving Arm and Link

Arm Adjustment

H

TO TIME THE FEED CAM

Tip machine bock, loosen the three feed corn

screws U, Fig. 25 ond turn caril clockwise for slower

feeding or counterclockwise for faster feedin g.

Tighten the three screws U.

TO REMOVE AND REPLACE THE KNIVES

Tip machine bock orid remove the two screws

G2, Fig. 26. Remove knife rack F2 by sliding it

up out of engagement with knife holder pinion E2.

This causes pinion E2 to rotate so that screw Q3

is accessible. Remove screw Q3. Remove knives

C2 and D2.

To reassemble, position knives C2 and D2 and

replace screw Q3. Mesh first tooth of knife rack

F2 with first tooth of pinion E2. Slide rack down

along driving bar and replace screws G2.

TO ADJUST KNIFE POSITION

AND KNIFE PINION

Fig. 26 shows knife C2 (shuttle thread knife)

and knife D2 (needle thread knife) in stop position.

Teeth in knife holder pinion E2 and knife rack

F2 must be properly meshed without binding or

looseness.

To eliminate binding, loosen the two screws G2

and screw H2. Slide adjusting block J2 down.

To eliminate looseness, loosen the two screws

G2 and screw H2. Slide adjusting block J2 up.

‘

After adjustment, tighten screw H2, reposition

knife rack F2 and tighten screws G2.

J2”;

TO TIME THE KNIFE

To time

knife roller.

knife action,

Tighten nut

‘7.

the knife, loosen nut V. Fig. 25, on

Move knife roller toward left for faster

or toward right for slower knife action.

V.

Q3

Fig. 26. Adjustment

of Knives

TO REMOVE ARM SHAFT END PLAY

1(32”

Before any adjustment is made on the stop mech

anism first check for arm shaft end ploy. End play

should be at a minimum without binding. To remove

end play, loosen arm shaft bushing set screw Q2,

Fig. 31, page 9 and turn hex support screw X2,

Fig. 27 inward. Tighten bushing set screw Q2,

Fig. 31. Recheck for a minimum of end piay with

out binding.

a

K3 !!N3

X2*

J

TO ADJUST THE TRIPPING MECHANISM

(For one or two-notch starting bell crank)

The tripping mechanism

locks starting lever

F3, Fig. 27 into running position by means of bell

crank pawl A2, Fig. 28 and bell crank B2, Fig. 28.

Before adjusting, make sure rock shaft D3, Fig.

28 is free from binding, particularly at upper support

E3, Fig. 29, page 9.

To adjust starting pawl and tripping mechanism,

first loosen socket screw Z, Fig. 28. Set tripping

arm A3, Fig. 25 to trip point X, Fig. 25 and leave

approximately .010” between bell crank B2, Fig. 28

and bell crank paw! A2. Tighten socket screw

Fig. 28.

I

1.

W2

Fig. 27. Removing End Play

z

A?

.011)

TO ADJUST THE STARTING LEVER

132:u

Starting lever F3, Fig. 27, page 8 carries en

gaging arm K2, Fig. 31 and all the recoil absorbing

mechaniSm.

I

C3

With the bell crank pawl A2, in catch C3, Fig.

28, there should be approximately 1/32 inch space

between high point of comminy face of fixed pulley

N3, and interlocking arm K3, as shown in Fig. 27.

D3

To obtain this setting, loosen swivel lock nut

63, Fig. 29 and remove hinge screw H3. Turn swivel

in or out as required. (Each full turn of swivel

equals approximately 1/32 inch of adjustment.)

Replace hinge screw 113 and tighten swivel lock

nut 63.

I

[I

TO ADJUST ‘IV” BELT

Keep belt tension only heavy enough to drive

machine without slipping. Excessive belt tension

will cause erratic stopping, shortening life of belt

and loose pulley bearing.

/

Fig. 28, Tripping Mechanism

With machine in an idle position, adjust belt

tightener, which carries motor, to obtain a distance

of 1-7/8 inches when belt is compressed as shown

in Fig. 30.

TO ADJUST THE ENGAGING ARM

Engaging arm K2, Fig. 31 drives idler pulley

N2 forward and forces “V” belt M2 forward and up

the face of fixed pulley, thereby driving the machine.

I

4

ing Lever Adjustment

With machine in operation, “V” belt M2 must

raise off bottom of idler pulley 1/32 inch, as shown

in Fig. 31.

ro adjust, loosen pinch screw W2 and tap arm

K2 in against engaging button Y2 until “V” belt

raises 1/32 inch when machine is operated. Tighten

screw W2.

WARNING A raise greater than 1/32 inch will

cause excessive belt tension.

-

N2

rims,

Fig. 30. Correct Belt Tension

I

:‘8’7i

Fig. 31. Adjusting the Engaging Arm

I I)

TO TIME THE STOP MOTION

Trip points X and W, Fig. 25, page 8 force powl

A2, Fig. 28, page 9 out of engagement with stcirtirig

bII crank B2, Fig. 28, thereby bring recoil mechan

sm into action to stop machine.

Trip Point X

)

1

sf0

position

—

determines when machine will enter

—

To adjust, bring starting lever F3, Fig. 27,

8 forward until powl A2, Fig. 28 drops into

first catch C3. Then set trip point X, Fig. 25 so

that, when rotating machine by hand, starting lever

F3, Fig. 27 will drop back against fixed pulley

N3, Fig. 27 just after interlocking notch M3, Fig.

27 has possed interlocking arm K3, Fig. 27.

page

Once properly adjusted, trip point X will not

require readjustment except when feed cam is re

timed.

Trip Point W determines speed at which machine

enters stop position

—

Trip point W will usually require readjustment

whenever the machine speed is changed.

F’g. 32. Stop Motion Brake

Excessive speed when entering stop position

will cause rapid wear and breakage of recoil mechan

ism. Therefore, on a machine not equipped with a

brake, check the trip point W often, for as machine

wears in and runs more freely, it will require a

longer coast period.

Adjust trip point W so that machine consistently

enters stop position at minimum speed when sewing

heaviest part of material.

TO INSTALL THE STOP MOTION BRAKE

Remove starting rod adjusting screw H3, Fig. 29,

page 9. Position brake bracket E4 as shown in

Fig. 32 and secure bracket to starting rod with

screw A4. Insert small end of spring support B4 into

small end of spring C4. Insert screw D4 through

bracket until it enters spring support B4. Continue

to turn in screw D4 until tension is applied to spring

C4.

Move starting lever G4 into running position.

Loosen lock screw 114 and turn adjusting stud (ec

centric) J4 until the brake lining K4 clears the

fixed pulley by approximately 1/32 inch. T

tighten lock screw 114.

L

Remove trip point W, Fig. 25, page 8. Run ma

chine and adjust for correct tension on spring C4,

Fig. 32 by turning screw D4 until interlocking arm

K3, Fig. 27, page 8 enters the stop notch quietly.

Then tighten lock screw F4, Fig. 32.

NOTE: As the brake surface becomes glazed

by use, it may be necessary to readjust the tension

on spring C4.

CAUTION: Brake lining must be kept free of oil.

11

INSTRUC’l’RDNS

When

Vi

FOR

ORDERING

un from Ihu lis

’

1

ts on t;hr follow

ing

[he SVCONI) Co

lumn.

use ONLY the

PART

ito uuuuinlucr stam

ped on a Sewing

.J

c single

Machine Part is

ofii

the

pail. only.

in every case the

number

tvery couiui)llIa lie

u of parl:s sent

out as such has

althou g.h not. sta in

its specific num

ped eu the pa rts

ber, which,

, must be used w

hen orde rin

I a:rti.cwi ar att euiti

g the combinatio

on shoe id be give

n.

n to the following

Wlitui o:i-deriiig

:—

pa i-ts where ther

e is any uncerta

nurube rs, state the

inty concerning

iunctions of the

the correct

parts and the Cl

machine for whi

as

s

and Variety num

ch they arc requ

ber of the

ired, to ensure a

or d er.

cor rect under sta

nding of your

This rut t applie

s as well to parts

that are ordered

mitted.

made as per sam

ple sub

‘l’o siuuiplJy recogn

ition of parts, ex

ploded views of

the mechanism ar

the various sectio

c shown in the sa

ns of

m

e

ill

ustration as the

Facing each illus

ass ernbly of thos

tration page is a

e

pa

rts.

list of parts with

THE FIRST COLU

KEY REFEREN

MN to indicate th

CE NUMBERS IN

e

lo

ca

tion of each part

key numbers are

in the illustratio

foi. reference in

n. These

this manual only

ordering parts.

and are NOT TO

BE USED when

The three digit nu

mber within the

parentheses, af

bers, is a CODE

ter some of the

number, indicatin

part num

g

sty

le

of finish only.

These codes MUS

T BE USED whe

n they appear in

nar.t number, as

the list, and AFT

in the list.

ER the

The following code

s indicate the sty

le of finish used

on listed Parts:

NEW CODE

OLD CODE

803

C

Hardened Only

804

D

Polished Only

805

E

Soft, Not Polished

806

F

Hardened and Po

lished

809

J

Nickel Plated Onl

y

813

R

Phosphate Coatin

g Formed on Surfa

816

ce of Iron and St

U

Zinc Plated

eel

819

X

Black Oxide, for

830

Iron and Steel

A. L.

Heat Treated for

To

833

ughness

A. L. X.

Heat Treated for

Toughness and Bl

850

ack Oxide

X. C.

Hardened and Bl

ack Oxide, for

869

Iro

n

and Steel

Commercial Fini

sh on Allen Type

Screws

this series:

1 to 1500, 50001

to 51500, 140001

to 142000, 200001

1500 are Screw

to Z01500 and 3500

Numbers

01 to

1501 to 1800, 5150

1 to 51800 and 20

1501 to 201800 ar

51801 to 52000,

e Nut Numbers

201801 to 202000

and 351801 to 35

ZOOl to 50000, 52

2000 are Roller

001 to 140000, 14

Numbers

2001 to 190000 an

.ving Machine Pa

d 202001 to 3500

rts

00 are

The figures in the

first column refe

r only to the plat

1 are NOT TO BE

es, illustrating th

USED in ordering.

e parts,

Parts prefixed w

ith a diamond ()

are furnish

:he factory.

ed only when repa

irs are made

-- -

12

P.A1.TS

A.RCI I C

Ref.

No.

239203

239202

68721

202(819)

239205

239204

68723

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

239201

350132(819)

239207

239209

239206

141575(803)

20171 1(803)

350605(869)

Z39Z08

68729

239248

201526(805)

350602(819)

239473

691(819)

239250

23926Z

239501

350645(805)

239474

29

239249

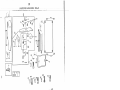

MACIJINI;

269 WH

A MP AN]) FEE]) PLATE CARRIER BAR

Pi vt

No.

239210

2

FOR

Description

Arch Clamp complete, Nos. 68729, 201

526(805), 239201., 239203,

239205, 239207, 239209, 239248, +239

249, 239473, 350602(819),

350605(869), two each 201711(803),

239206,andfive 350132(850)

Arch Clamp Foot Shank (left) 239202

with 202(819) and 68721

Foot Shank (left)

Foot (left)

Foot Screw (2)

Arch Clarnp Foot Shank (right) 2392

04 with 202(819) and 68723

Foot Shank (right)

Foot (right)

Foot Retaining Plate

Screw (5)

Frame (universal) with two 239208

Rubbing Block

Spring (medium) (2)

Spring Adjusting Screw (2)

Spring Adjusting Screw Lock Nut (2)

Frame Screw

Frame Dowel Pin (2)

Feed Plate

Plate Carrier Bar with 350645(805)

P.late Nut

Driving Block Screw

Cover Plate (top)

Cover Plate Screw (6)

Stud

Carrier Bar Connecting Arm

Driving Block Pin

Feed Plate Screw Stud

Feed Plate Carrier Bar and Cylinder Cov

er Plate (top) complete,

Nos. Z39Z48, +239249, Z39473 and 35060Z(8

19)

(for repairs only)

Feed Plate Carrier Bar Driving

Block with 239501

.1

I

pz

r=

c-I

c_I

>

2

L

>

>

7.

‘C

rn

z

n

z

>

0

H

U,

-v

>

14

iAi’IS

Ak M

Nn.

I

IA Ii,

Na.

401’IS

50650(81)3)

:3

4

5

6

7

8

9

10

11

239:385

239khz

239331

239)30

12166

249915

239143

200363(830)

23477

12

13

14

15

16

17

18

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1065(830)

858(830)

1258(830)

1036(830)

203172

239228

223847

223847

239229

239227

239224

239314

239347

201220(833)

200382(833)

167012

202299

239374

141 l8(833)

239383

200325(803)

53618(805)

239486

167013

35

36

37

38

39

40

41

42

239315

239318

239317

239322

239382

239526

239525

239524

I’C).R

:f’A.Acil1NI;

269 W8

MA(;I IINV PU I J i;y ANI) NI;I:DLI; BAR CRANK

Description

Needle 13d .r C meeting Link

I ,inI’ C;ij) Sc l(V’

1h.ri;id T.i k(—up C rank

TSr (‘ad Tak (‘— [[p Leve camp I ete, No s Z39 330 and 23933 1

Lever Link

Li k — UI) LeV( r

Lever I-huge Pin

Lever I i nk I-tinge Pin with 239143

Lever Link I-huge Pin Oil Packing (wick)

Lever Link I—hinge Pin Set Screw

Needle Bar Crank with 858(830), 1036(830), 1065(830) and 1258(830)

(for Agents only)

Crank Posit [on Screw

Crank Set Screw

Take—up Crank Set Screw

Take-up Crank Position Screw

Friction Washer

Bushing (front)

Bushing (center) Oil Packing (wick)

Bushing (front) Oil Packing (wick)

Bushing Oi.1 Tube (2)

Bushing (center) (for Agents only)

Arm Shaft

Machine Pulley (tight) Key

Vertical Drive Shaft Worm with 200382(833) and 2012Z0(833)

Worm Position Screw

Worm Set Screw

Arm Shaft Bushing (back) (for Agents only)

Bushing (back) Oil Packing (wick)

Machine Pulley (tight) Needle Thrust Bearing

Bushing (back) Support Screw

Washer (2)

Bushing (back) Set Screw

Bushing (back) Support Screw Lock Nut

Machine Pulley (tight)

Arm Shaft Bushing (back) 167012 with 53618(805), 141128(833),

202299, 239374 and two 239383

Machine Pulley Retaining Ring (2)

Machine Pulley (loose) 239317 with 239322

Machine Pulley (loose)

Machine Pulley (loose) Needle Bearing

Machine Pulley (loose) Starting Cap Thrust Plate

Machine Pulley (loose) Starting Cap Thrust Bail Bearing

Machine Pulley (loose) Starting Cap Thrust Button

Machine Pulley (loose) Starting Cap

‘

Q%

C••4

LIJ

U

o

H

z

U

-

z

-4

U

F

ID

0

A

UI

F— Z

I-

7

.1

/

-

I6

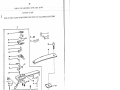

PARTS [‘0 R MACIl IN I

269 W8

I< NI .I’V BAR AN I) OSCI Ii .A’[ [NO ShAFT ASSFMh3LTE

S

Ref.

i.’ci

.

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Z3

24

25

26

27

28

29

30

31

32

33

34

35

35

36

37

38

39

40

41

42

I

ri.

N>.

239251

239253

239261

239260

1

IJcs

t

ioi

cri

i

Rn.iv Bar

239253 with 239260,

Kiiii e Ba r

Adjusting Block

Knife Bar Rack

Scre\V Washer (4)

239261,

three each 202603 arid

3501 32(81

202603

350132(819) Screw (4)

239284

Bushing (front—outer) with 201472(803)

201472(803) Bushing (front—inner) Set Screw

200333(830) Bushing (front—outer) Set Screw

239283

Bushing (front—inner)

239550

Oscillating Shaft

239282

Bushing (back)

239145

Oscillating Shaft Crank complete, Nos. 1636(805), 24050

and 239551

24050

Slide Block complete, Nos. 226(809), 1035(803), 12424 and

19448

226(809) Crank Slide Block Cap Screw

[2424

Crank Slide Block Cap Screw Washer

19448

C rank Slide Block

1035(803) Slide Block Screw Stud

239551

Oscillating Shaft Crank

23955Z

Crank Pin

1636(805) Screw Stud Nut

13275

Oi.l Pad (felt)

39653

Oscillating Rock Shaft

201749(805) Hinge Screw Nut

239280

Oscillating Rock Shaft Hinge Pin 239279 with

23421 and 222583

239279

Hinge Pin

222583

1-Tinge Pin Oil Packing (wick)

23421

Hinge Pin Oil Hole Plug (leather)

200394(803) Hinge Pin Set Screw

908(803) Rod Hinge Screw

20197

Crank Connecting Rod with 125044 and two

896(803) (for Agents only)

896(803)

Rod Cap Screw (2)

125044

Rod Oil Pad (felt)

201083(803) Knife Actuating Lever Screw

213484

Knife Bar Connection Stud Slide Block

213484

Knife Bar Driving Slide Block

200689(803) Slide Block Screw

350447(804) Connection Screw (2)

239257

Knife Bar Connection with 213484 and +2392

58

239251

Knife Actuating Lever

239252

Knife Actuating Lever Link

239146

Oscillating Shaft 239550 with 239145 and 239552

239553

Oscillating Shaft 239550 with 239551 and 239552 (for Agents only)

+239258

Knife Bar Connection Stud

L

17

PARTS FOR MACI-IINF 269w8

1N I I’E I A I A NI.) OSCII JAi’TN(

STIA Ii’ .ASSI M I I IES

31

()

jo

39-

I35—

Li2Ij

3

B

t3rR36

30

-Z6

2

41

13

8

9

20-

to

8

I ‘.AIi

KNlV)

II

No.

2

3

4

3

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

I ‘i .rt

No.

1 6/009

Z0008’I(8] 9)

239339

239338

1208(809)

5325

239337

5001 8(806)

239368

1198(803)

206133

239372

55459

17825

17830

17826

7298

17827

17828

201711(803)

239367

200138(805)

239236

691(806)

200004(805)

141577(803)

204235

239233

Z00294(81 9)

350618(803)

239234

239221

200582(819)

239223

200064(819)

201 072(805)

167262

1053(806)

+Z39230

$239231

+239220

I’()1.

IvIAC1 lINT;

29W8

tvl-C1llANI()tJS (0V11’S AN)) i’Tl1()A’[ .Pli\’TJ;

1•

I_)vscril)tiou

A:rin CoVer (Iront) with 1053(806) and 167262

CV(W (4)

Throat Plate with 1198(803), 55459, 2001 38(805), 206133, 239367

and 239372

Throat Plate 239337 with 55325 arid two 1208(809)

Needle I lole Bushing Screw (2)

Needle Hole Bushing (46 needle hole)

Throat Plate

Pinion Stud Bracket Screw

Knife Holder complete, Nos. 1198(803), 17825, 55459, 206133 and

239372 (for Agents only)

Screw

Wahr

Knife (Needle Thread)

Knife (Shuttle Thread)

Knife Holder with 17826, 17830 and two 7298

Position Pin

P4 n ion

Pinion Dowe.l Pin (2)

Pinion Stud

Knife Holder Pinion Stud Bracket with 17827

Stud Bracket Screw Nut

Knife (stationary)

Knife (stationary) Screw

Oil Stop Pad (felt)

Screw (4)

Screw (5)

Belt Guard Lock Spring Screw Stud

Position Pin (4)

Cylinder Cover (bottom)

Cylinder Cover (bottom) Screw (2)

Locating Screw (4)

Cylinder Cover (side)

Arm Cover (center)

Arm Cover (center) Screw (2)

Arm Cover (side)

Arm Cover (side) Screw (4)

Cylinder Base Locking Screw

Arm Cover (front) Thread Cutter Knife

Knife Screw

Cylinder

Cylinder Base with 200364(803) and 239361

Arm with two 239229

/

V

(‘4

‘V

\

I?

1-

_;

---

-

3

(‘4

r3

—I,

;—-

I::

1

//

>

-

>

2s)

iL

LU

ihi.

No.

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

I

No.

l.All.- VOl< vlA(,IllNl; 2(-)wK

LA[’f;RAI. i\ND lONC;.ll:Ul)INAL ROHK Sl[A11

.$

I )‘ ci.- ipl.i (Hi

01 P;I(:IciIiI (wek) (2,)

I)i’.iv(’ii /\iiii I IiiiI’(’ StII(I \‘itl 2,02<123 (2)

SLl: Serew (2)

I’u(k iii;iJl. ).riven i\.riii (2)

23957<1

I)rfviii Arili Scrt’’,v iI:iid (juide 13[c)clc. (2)

231)2.69

I )riv:i ii A:rin SCrew Stud (2)

239268

1)riv iii A. rin with 350604(809)

:35060.1(869

.15 neli Screw (2)

210805

Waihtr (2)

201652(805) Nut (2)

268072

(3o1 I ar w ttli tWO 200386(803 ) (2

200386( 803) Set Screw (4)

239384

Lo

i

5

tticlijia

n 1 Rock Shaft

51946

RoLler and Stud with 1655(803) and.37310 (2)

200545(803) Link Screw

239266

Lateral Rock Shaft Driven Arm Driving Link

239263

Lateral Pivot Driving Arm with 350600(869)

350600(869) Pinch Screw

201518(805) Link Screw Nut

239264

Lateral Rock Shaft

37310

Washer (2)

1655(803) Nut (2)

239343

Tripping Rock Shaft Lever Arm

200082(805) S c r

239340

Tripping Rock Shaft

239361

Arm Hinge Stud

200364(803) Set Screw

239240

Link Hinge Stud

239241

Link Retaining Ring

239239

Link

239238

Cam and Knife Follower Arm with 239Z39 and 239240

201539(819) Roller Screw Stud Nut

225837

Roller Screw Stud Washer

351886

Knife Arm Roller 201896 with 350634

201896

Arm Roller

350634

Roller Screw Stud

239255

Knife Bar Actuating Rock Shaft

239256

Rock Shaft Bracket

201256(803) Bracket Screw (2)

239363

Bracket Locating Pin

239259-001

Knife Bar Driving Lever with 200034(803)

200034(803) Pinch Screw

234813

Collar with two 201052(833)

201052(833) Set Screw (2)

239344

Tripping Rock Shaft Support

200378(803) Set Screw

239341

Tripping Rock Shaft Connection with 3 50606(869)

350606(869) Pinch Screw

239144

Longitudinal Rock Shaft 239384 with 51946

202’l 2,

)Z(7

1

2i

2003 i5(H0)

2:9205

j

(0

/

C’,

H

0

z

H

b

z

C..

z

C)

0

(I)

—

>

‘I’S

I’( )R

MA (liii N I;

2( W 8

11 ‘I’I 1 I’ IA I A NJ I) A L(1 I C I ,A MP I il’’FINC kOCK SI1i\.I.’’’i’ ASSI’ivlB I ,y

III’’

No.

2.

7

H

1)

10

11

1 2.

13

14

15

16

17

18

19

20

-

21

22

23

24

2.5

26

27

Z8

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

No.

2392.

200I .;0(830

Description

iit:1

]‘oclc ;1i1t; \k’I]I 200’130(8_30)

Link Connection Sc:rvw

Nt ud ( I hi r B ii shing (per

9) .1 ressuru Rt’gtilatin Screw

2392 Ii

-;J)J ng

239217

1fti ug Link

I iii 511)11 Release Rod

2392] 3

Posi tin ii Guide with 200072(803), 239Z 17 and 23951 5

7.39 5 1!)

Li ILl ug Link lii nge Pin

21)0072(803

Pinch Screw

2392.76

Connecting Stud 239275-001 with 200086(833) and 239277

2.39275-001

Connecting Stud

200086(833) Stud Pinch Screw

239271

Stud Oi.1 Packing (wick)

239218

Lifting Link Connection

239212

Lifting Bar Bushing (lower)

239211

Arch Clamp Lifting Bar with 176(819)

239273

Needle Bar Bushing (lower)

Z39 272

Needle Bar with 200125(833), 201143(819) and 239376

239390

Thread Wiper (quick acting) complete, Nos. 330(809), 39453, 63837(

141574(803), 200308(803), 239336, 239387 to 239389 (for Agents only,

63837

Arch Clamp Foot Lifter

330(809) Thread Wiper Body Finger Screw

39453

Thread Wiper Body Finger

176(819) Screw

239376

Needle Bar Thread Guide

201 143(8 19) Guide Screw

200125(833) Needle Set Screw

239389

Thread Wiper Body Wire (adjustable)

239336

Wire Clamping Plate

141574(803) Wire Clamping Plate Screw

239387

Thread Wiper Body

200308(803) Body Hinge Screw

239388

Body Support

200337(803) Body Support Set Screw

239487

Starting Lever Lifting Rod

Z3921 6

Lifting Arm with 201256(803)

201256(803) Lifting Arm Pinch Screw

167143

Starting Bell Crank

1 67 144

Crank 167143 with 51657(805), 53617(805), 167154 and 167155

53617(805) Swivel Stud Lock Nut

46

Z39294

Starting Bell Crank F

141065(803) Hinge Screw

47

239295

Pawl Return Spring

239299

Lifting Rod

48

239342

Connection Rod

167154

Starting Rod

49

20 1083(803)

Pawl Hinge Screw

167155

Starting Rod Adjustor

50

259470

Collar with 201188(803)

51657(805) Rod Lock Nut

51

Z01188(803)

Collar Set Screw

(_.liiiii_>

i.itiiig

tiitiflJ

23

PARTS OR MACHINE 269w8

NEEDIF BAR AND ARCI-I CLAMP LIFTING ROCK SHAFT ASSEMBLY

3)

50

36

r Lf

8

ZJL

‘F;

I

4

I7

ii

3

I NCHS

34

19

20

(4l

32

7

c:ç

293w

24

/28

22—.

Needle:

Catalog

1628

(68x5)

Size 18

23

-

24

I A R IS

Sit ill’ iJ

1f.

No.

I’. I

No.

2

3

‘1

5

6

7

8

9

10

1 5141

15140

2973

2974

592(805)

2975

224842

591(806)

43725

11

12

13

23500

40028-002

239292

14

15

16

1.7

18

19

20

21

22

23

239290

23928

201148(819)

51381(806)

239291

239289

239365

51403(869)

262061

350606(869)

IOfl

MACi IN 1

!‘,OKKiN AN!) RAC1

269 W8

.ASSIMBLiIS

Dt s(: ri.pI:io fl

ShoW e, 1—11/16 in. cliam.

NTos. 23500, 40028—002 and 43725

Iii ige, Nos. 2973, 2974 and 1 5140

at.ch

I a I.cli I (Ve 1

Latch Lever Lii cr urn Pin

I .aI;c1i Stop Sc rew

Latch Spring

Tci sion Spring

Regulating Screw

Shuttle Bobbin Case with 591(806), 592(805), 2975, 15141 and

224842

Shuttle Bobbin

Shuttle Body

Shuttle Race complete, Nos. 239285, 239289, 239290, two each

51381(806),201148(819) and 239291

Race Ring

Case Position Plate

Case Position Plate Screw

Ring Spring Screw (2)

Ring Spring’(Z)

Body with 239365

Body Oiling Felt

Body Screw (2)

Shuttle Driver (central bobbin) with 350606(869)

(central bobbin) Pinch Screw

,

25

PARTS FOR MAC[1IN 269

w8

SIll 11,1 LE BO1IHIN

AND RACE ASSEM

BLIES

34I

/

I

22{23

1

[F

i

[NCHES

‘21

‘

I ‘A

I

i’’( 1 lviJ\ ( I I I’ 2(e) \‘V 8

SIA II’IN

IJ;v I’I \;I;ftiIjJ,y

Ne.

1

2

3

‘1

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Ne.

235)2’5)6

I

r

ii )t:

C)

S

L[

ii.iiig I

with 2003b1(81)3)

23) ;o•i

I fling .i ng

350 [12(80’)) SJ)1ing Screw Stud upper) (2)

(

2 [4()53

Spring (2)

201442

Ik

tion Sen w 1 in

167158

Step Rod BCII1Ip(r SCpa ratiu

’ Washer (8)

1

239303

Operating I cver A r fli

201 422(80:3) Arm Stud Screw

Z0[356(805) Scr iw Stud (lower)

239301

Bushing

200364(803) Set Screw

239133

Starting Lever Arm and Rock Shaft (adjust

able) with 423(830),l650(8C

20135(803), 201442(803), 201525(805),

228810, 228812 and 232837

201525(805) Spring Stud Nut

228810

Spring Screw Stud

228812

Tension Pulley

232837

Tension Pulley Retaining Screw Washer

201135(803) Tension Pulley Retaining Screw

239159

Interlocking Arm

239517

Interlocking Arm Stop Rod

202342

Stop Rod Hinge Pin Tension Spring

239518

Stop Rod Hinge Pin

131022

Stop Rod Bumper (rubber) (4)

239310

Stop Rod Swivel

228032

Stop Rod Swivel Washer

1518(805) Nut (2)

239549

Stop Motion Brake complete, Nos. 167229, 200428(803), 20]. 075(80

6),

223812, 239511 to 239513, 239557 and 350676(850) (for Agents

only)

239557

Brake Shoe Support 239554, 239556 and two 239555 with 239508

239554

Stop Motion Brake Shoe

239556

Brake Shoe Support

201075(806) Support Hinge Screw

223812

Support Spring

239511

Support Bracket with 200110(804) and 350411(803)

350676(850) Bracket Hinge Screw

239513

Support Bracket Stud (eccentric)

200110(804) Support Bracket Stud Screw

167229

Support Bracket Pressure Spring

239512

Pressure Spring Sleeve

35041 1(803) Pressure Spring Adjusting Screw Pinch Screw

200428(803) Pressure Spring Adjusting Screw

239519

Stop Cam Interlocking Arm Stop Rod Hinge Pin Retainer

239520

Interlocking Arm complete, Nos. 202342 and 239517 to 239519

201527(803) Swivel Nut

423(830) Starting Lever Arm and Rock Shaft Stop Screw

1650(805) Stop Screw Lock Nut

239555

Brake Shoe Rivet (2)

S

—

N

N

N

N

N

d

i

N

N

‘

\

>

>

(••)

-

rn

<

20

H

>

H

ZLfl

1ARr;

I:N A( IN A 3M,

i’013

MACi1IN1

ii 1k VAD GUIDI;,

3o)

W5

11 I;’I’AIN I135 AND

‘I I;Nb I(N (([v1 UI

N.

I i

Nu.

—‘:3

I

/,39.6

3

(

‘/

13

9

10

11

12

13

1i

15

16

1.7

18

19

-t

20

21

22

23

24

25

26

27

28

2.9

30

31

32

33

00 3 / /(1W 3)

082

2/02/b

].‘i I 5/ (80.

2102

32572

2103

1 bbO(803

239328

200366(1319)

200442(803)

210954

200582(819)

270080

350559(819)

271018

223711

223710

200397(833)

200582(819)

2.10993

223844

21 0957

210958

239381

Z39379

239320

239321

350600(869)

239380

201747(819)

N

Disc r.plioii

1560(803), 2103, 32572, 5Z08Z,

141 57(803), 210278, 270281 ;iiicl two 2102

uI,I.or with 201) 377(803)

1

:J) rfl) R&’

l(Ju;ion Stud $tt Set-ew

r(;I (I F1 IIj) Spriu8

[‘cii H Oil I-i (i Hi Ii Piii

ion

IliHioli Disc (2)

‘F i.ii siou .Ri1 casing Di sc

1(11 jo ii S p ru i g

Tension Thuiiib Nut

jension Thread Guard

‘[‘crision Thread Guard Set Screw

Thread Take—up Spring Regulator Set Screw

Thread Guide

Thread Guide Screw

Thr cad Retain ci- (front)

Thread Retainer Screw (2)

Thread Retainer (back)

Thread Retainer (lower) complete, Nos. 210957, 210958,

210993, 223710 and 223844

Thread Retainer (lower) with 200397(833)

Retainer Stud Set Screw

Retainer Screw (2)

Sic eve

Spring

Stud

Stud Collar

Machine Pulley (loose) Engaging Arm 239379 with 239380

Engaging Arm with 239320, 239321 and 350600(869)

Wear Block

Wear Block Pin

Pinch Screw

Machine Pulley (loose) Engaging Arm Stud with 201747(819)

I’enHJuI) corn i.[vte,

Lock Nut

[‘los.

(I

C

-D

LIJ

0

-

-4

H

LZ

LI

N

ID

C%J

A

0

Di

w

‘I.,

-

Di

\ \\

.31)

PARiS

V I; k ‘1’ [CA I

lOR

MACI tIN I;

269W8

I )k 1 V I; Si IA 1”[ A Ni) F V V 1)—A Ni)—KNJFE—1)RTVING CAM

-

Re[.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

.1 ;i rt;

No.

239348

200362(803)

200354(830)

239346

239364

2393’iS

239523

202005

350627(869)

239522

239245

239237

239247

200064(803)

350601(803)

210805

350600(869)

Dcsc ription

Worni Gear with 200354(830) and 200362(803)

Worn (x.ear Set: Screw

Worm Gear Pcsition Screw

Bu.sli:ing (upper)

B u shing (lower)

Vtrticai.Dr ive Shaft

Bracket

Bracket; Scr evv Washer

Bracket Scrcw

Supporting Gear with 239245

Locating Pin

Feed and Knife Driving Cam with 200064(803) and 239247

Tripping Point

Tripping Point Screw

Supporting Gear Screw

Mounting Screw Washer (3)

Mounting Screw

(

Cr)

UJ;r

I’A1’I

l(>F<

(

RH.

No.

No.

1

228800

2

167292

3

4

5

462(8.30)

228798

200084(850)

6

7

268122

5989

8

9

10

11

12

13

14

418(804)

2455

10141

1562(819)

228792

350238(804)

239158

15

16

172

228793

200436(803)

228795

249716

201 256(803)

239157

228796

50628(809)

225459

225458

50356(804)

1620(819)

202478

200056(805)

225444

200299(819)

228794

239558

18

19

21

22

23

24

25

26

27

28

29

30

31

32

)K

N4A(:iiIN;

IN

269V8

VV IN )I R

I )sc .I.iI)tiU1)

I iglil: and I’()bbill \‘Viiider .[hi’v;i ci Tens ion AcIjttstiru Stud

B racket 1 67292 w:ith 5989, 228/98 and 268122

I ght nicI 13oIbin W:incler ‘[h.read ‘1 ciision Adjusl:irig Stud

Bracket wit:li 462(830)

1eiisicjti Adjusting Stud Set Screw

‘I ens ion Adjusting Stud

Light and Bobbin Winder Thread Tension Adjusting Stud

Bracket Set Screw

Tension Guide

Bobbin Winder Thread Tens ion complete, Nos. 418(804),

1562(819), 10141 and two 2455

Tension Stud

Tension Disc (2)

Tension Spring

Tension Thumb Nut

Brake (leather)

Brake Screw (2)

Bobbin Winder complete, Nos. 1620(819), 50356(804),

50628(809), 200056(805), 200299(819), 202478, 225444,

2Z8793 to 228796, 239157, 249716 and two 225459

Pulley with 200436(803)

Pulley Set Screw

Spindle Housing

Spindle I-lousing Spring

Bracket Screw

Bracket

Stop Latch Thumb Lever Plate

Stop Latch Thumb Lever Plate Screw

Joint Stud (2)

Stop Latch Thumb Lever

Spindle Housing Screw

Spindle Housing Screw Nut

Stop Latch Trip Lever

Stop Latch Screw

Stop Latch

Stop Latch Trip Lever Hinge Screw

Spindle with 239558

Bobbin Winder Bobbin Locating Pin

22547.

33

PARTS EOR MACHINE

269w8

EOi3fIN WINDER

7

/

urnnJu

3

1/

‘4

H,,\gIL;

Si\ M V AS /\ 0(1

R’.

Nt.

I ii.

No.

()

/\

21’)\VS

ANT)

Z69v]7

I’d JIlON C LAML

Mi’ UN M A H TINT; 269 W8 W Jill Ill I; FOIl OWING IX( vPi 0 )NS

‘

2 9I 2l

2

3

4

5

(H

IA(Hi1NI;g

6 591$

i 3659’)

Ii I 91)

I 36 (,00

1 5 3 /9

7

8

9

10

11

12

13

14

15

I 36601

1366(32

136603

124732

17710

1176(1319)

6 87 99

124733

16

17

18

19

20

zi

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

124734

124735

239123

50117(809)

1484(809)

99(813)

39241

239572

1177(819)

17714

1178(819)

39335

39242

136608

124737

124738

1182(809)

17718

124739

50237(810)

17719

1181(819)

63742

17720

63741

1199(819)

/28(8 19)

l)escriptioii

(11]]1 (‘Ilpiete, Nos. 99(1313), 1181(809), 1183(809), I 199(81’

1771’), 39242, 50237(810), 63741, 124732, 1 24733, 124734, 1 Z473?

I 24738, 1 24739, 136 599, 1 36602, 1 36608, two (tch 1175(805),

17718 a,id four 1182(809), i P

C ç,f 239210

1

i’,iittoii

110 tt( Hi CIiiip (hit.) with 17723, 45329 and three 36696

1, i ti i

CIoiip (left) 136598 with 228(819) and 136600

(H LIlflj) ILC1 1ui (6)

( I LI] p (I eft) Spring

ring l()SitiO]l lin (2)

Spring Screw (2.)

11’ittou Clamp (right) with 17723, 45329 and three 36696

ut toli Clamp (right) 136601 with 228(819) and 136603

C Ia top (right) Spring

CI LLO113 Arm with 17714 and 68799

Arm I--Tinge Plate

Arm Hinge Plate Screw

.Arni F-Took

Clamp Opening Lever

Opning LLver Bracket

Openmg Lever Contact Piece

Contact Piece Arm

Contact Piece Arm Screw

Contact Piece Screw

Opening Lever Hinge Screw

Clamp Pre

Spring

Spring Bracket

Bracket Screw

Spring Guide Block

Spring Screw

Spring Screw Plate

Clamp Spreader

Clamp Stop with 17720 and 63742

Spreader Lever

Spreader Lever Adjusting Plate

Screw (4)

Washer (3)

Spreader Lever Stop

Stop Position Screw

Spreader Spring

Spring Screw Stud

Spreader Steady Pin (long)

Spreader Steady Pin (short)

42

Spreader Thumb Plate

43

Thumb Plate Screw

44

(

ssure

—

1183(819)

17723

1175(819)

Stop Screw

Clamp Stud (2)

Clamp Hinge Scre

zm

0

H

C

2

‘1

z

>

2

>

>

>

-r

-D

>

2

>

>

LI

I

-‘I)

-,

PARTS FOJ. MACIT1N[;S 2.69W

1 AND 269 W17

10k STII.CI1ING 2 011 4 IIOLL BUTTONS

SAMV AS MACIIINI; Zb)W8 WiTH T1TV FOLLOWING l;XC1;PTIONS:

Rel.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

I >;i r

Nu.

239537

/

Description

l)evic V complete, with graduations and two external hand

operated I (VI r s for quick adjusting of the lateral and longitudinal

nuchanisro, Nus. 1654(803), 141550(830), 239533, 239534,

239535, 2.39536, two each 1620(805), 141545(830), 194328,

2.00362(803), 201783(803) and three each 202248 and 20262.2..

239533

Cylinder Cover (side), in place of 239234

2.39534

Late i-al Adj us t::i rig Lever

1415115(830) Hinge Screw (2)

1620(805) Hinge Screw Nut (2)

239583

Lateral Rock Shaft Driven Arm

Longitudina.1 Adj usting Lever

239535

239536

Lon gitudinal Adj U sting Lever Handle

141550(830) Lever 1-linge Screw

1654(803) Hinge Screw Nut

167287

Longitudinal Feed Plate Carrier Bar Positioner

202248

Hinge Spring Washer (3)

202.622

1-linge Screw Washer (3)

201783(803) Screw Stud Nut (2)

200362(803) Screw Stud Locking Screw (2)

194328

Screw Stud Washer (2)

2.39586

Feed Plate, in place of 68729

239573

Feed Plate Carrier Bar with 141560(805), in place of 239248

1654(803) Feed Plate Nut, in place of 201526(805)

141560(805) Feed Plate Screw Stud, in place of 350645(805)

239151

Shuttle Race Body with 239365, in place of 239289

210993

Thread Retainer Sleeve

272208

Thread Retainer Spring

210957

Thread Retainer Stud, in place of 270080

210958

Thread Retainer Stud Collar

239121

Thread Wiper Body Support 124777 with 1207(803)

124777

Thread Wiper Body Support, in place of 239388

1207(803) Thread Wiper Body Hinge Screw, in place of 200308(803)

200084

Cylinder Cover (side) Screw (2)

239269

2.39574

239365

Iuliti sting

Screw Stud (2)

Screw Stud Guide Block (2)

Shuttle Race Body Oiling Felt

Catalog 1627 Needle (68x3) Size 16

239152

Shuttle Race complete, Nos. 239151, 239285, 239290, two each

51381(806), 201148(819) and 239291, in place of 239292 (for Agent

only)

239122

Thread Wiper (quick acting) complete, Nos. 330(809), 1207(803),

39453, 63837, 124777, 141574(803), 239336, 239387 and 239389

(for Agents only)

Ii

NJ_g

9

6?

c —€

Ii

I—

ç,— 9!

oc —ci

O

—-

y

9

(‘

(IN V

£

ci

t71

£ —ç

c2>— 91

w--—-

ci

-N()i]iI)\,i )Nii\Y

i’iOi :iiii iii.IA’\ H/vh

g’

-NOiLii

1.1 iV

INiIi:)Vi’

\‘ :ii’N\/!;

110?? I’ NO ? 0Niii:)III

K),i

N (‘i?

N ii )\/ i”

H ( ) 1

0 H

: H

I ‘ARTS

EUl

MACI TIN i:s

269W 5

AND

269 WI 7

FOk SIlT Cli INC 2 OR 4 hOLE BUTTONS

SAMV AS 269W8 w.IT:l1 TilE FOLLOWiNG EXCEPTIONS:

PARIS FOR MAChINE 269W5 ONLY

23957 I.

2

3

200064(803)

239247

239 i 31

1’ ced and Knife Driving Cam with two each 200064(803) and 239247,

(X stitch) Regular, in place of 239237

Tripping Point Screw (2)

Tripping Point (2)

feed and Knife Driving Cam with two each 200064(803) and 239247,

( stitch), in place of 239237

PARTS FOR MACHINE 269 Wl7 ONLY

1

239142

4

239577

5

6

7

8

9

10

11

12

450(833)

453(830)

239578

140732(830)

448(830)

239132-001

239141

17829

239154

239156

Feed and Knife Driving Cam with two each 200064(803) and 239247,

in place of 239237

Vertical Drive Shaft Worm with 450(833) and 453(830), in place of

239347

Vertical Drive Shaft Worm Position Screw, in place of ZO1ZZO(833)

Vertical Drive Shaft Worm Set Screw, in place of 200382(833)

Vertical Drive Shaft Worm Gear with 448(830) and 140732(830),

in place of 239348

Vertical Drive Shaft Worm Gear Position Screw, in place of 200354(8

Vertical Drive Shaft Worm Gear Set Screw, in place of Z00362(803)

Lateral Feed Plate Carrier Bar Positioner

Throat Plate Needle Hole Bushing, in place of 55325

Knife Thread Bolder, in place of 206133

Throat Plate 239337 with 239141 and two 1208(809), in place of

239338

Throat Plate 239154 with 1198(803), 17825, 17828, 17829, 50018(806)

55459, 200138(805), 201711(803), 239367 and 239372, in place of

239339

39

)‘AkI;

‘ok

vIACI(INTS

10k Ilic’.(llN(;

A;

(‘)VVk \V ITI I

[I lI’

Z6)’V

i\Ni)

Zb)\V

7

(I ‘1 1IOLI; IU’[TON

I(I 1 (,)\VIN( .IX(,I’i’I’i

QN’:

4

7

II

10

[‘A Rl:S

i’Oi.{

l’().R

hA MI AS MACI liNk

Rei.

No.

I

ci

No.

I

2

3

4

5

6

7

8

9

10

11

12

13

239465

239202

202(819)

239463

239466

239204

39304

239469

239337

239468

1208(809)

239471

14

15

16

200382(833)

201220(833)

239472

17

18

19

200362(803)

Z00354(830)

239461

20

21

200064(803)

239247

239464

239467

239470

Cat. 3072

MAChINE

5110 I

269 W7

TA(;K NC

9W8 W liii TI I I FOLLOWING 1;XC1;PT1ONS:

I)vscriptioii

A cli (

Foot. hhuik (left:) Z39202 with 202(819) and 239463

loot Shank (lift)

loot Screw (2)

Arch Clamp Foot (left)

Arch Clamp Foot Shank (right) 239204 with 202(819) and 239464

Foot Shank ( right)

Arch Clamp Foot (right)

Feud Plate

Throat Plate 239337 with 239468 and two 1208(809)

Throat P[atc

Throat Plate Needle Hole Bushing (40 needle hole)

Needle 1-Jole Bushing Screw (2)

Vertica.l Drive Shaft Worm with 200382(833) and 201220(833), in

place of 239347

Worm Set Screw

Worm Position Screw

Vertical Drive Shaft Worm Gear with 200354(830) and 200362(803),

in place of 239348

Worm Gear Set Screw

Worm Gear Position Screw

Feed and Knife Driving Cam with two each 239247 and 200064(803),

in place of 239237

Tripping Point Screw

Tripping Point

Arch Clamp complete, Nos. 39304, 201526(805), 239201, 239207,

Z39209, 239248, •239249, 239465, 239466, 239473, 350602(819),

350605(869), two each 141575(803), 201711(803), 239206 andfive

350132(850), in place of 239210

Throat Plate complete, Nos. 17828, 50018(806), 200138(805),

201711(803), 239367, 239368 and 239469, in place of 239339

Needle (16x100) Size 16

41

FOR MACI-HNIE 269w7

1’()R SHOE JACKING

SAM1 AS MACIIIN[ NO.

269W 8 WITH ‘1’JJ1 [iOLI ow1N(;

EXCEPl’IONS:

5

9

-12

PARr S

F OR

MJ\ Cli IN.I

.1.01< I.A l<.R,[NG BUTtON I 10 LES,

269 W 9

FASI’ [NJNG BOWS AND OTI-IER

0iNA1v1lNT S ON SI-TOIS OR GARMLNTS.

(

SAM!; AS MACHINE Z69W8 W1TI.1 TilE FOLLOWING EXCEPTIONS:

Ref.

No.

.1 t- I.

No.

1

239406

2

3

239247

200064(803)

55326

239403

239202

202(819)

239401

239404

239204

239402

18459

55458

210993

272Z08

210957

210958

4

5

6

7

8

9

10

11

12

13

14

15

16

17

239405

239532

239126

239127

Description

Feed and Knife Driving Cam with two each 239247 and 200064(803),

in place of 239237

Iripping Point (2)

Tripping Point Screw (2)

Throat Plate Needle I-IoIe Bushing

Arch Clamp Foot Shank ([eft) 239202 with 202(819) and 239401

Foot Shank (left)

Foot Screw (2)

Foot (left)

Arch Clamp Foot Shank (right) 239204 with 202(819) and 239402

Foot Shank (right)

Foot (right)

Feed Plate

Knife (needle thread), in place of 239372

Thread Retainer Sleeve

Thread Retainer Spring

Thread Retainer Stud, in place of 270080

Thread Retainer Stud Collar

Arch Clamp complete, Nos. 18459, 201526(805), 239201, 239207,

Z39209, 239Z48,239249, 239403, 239404, 239473, 350602(819),

350605(869), two each 141575(803), 201711(803), 239206, and

five 350132(850), in place of 239Z10

Knife Holder complete, Nos. 119 8(803), 17825, 55458, 55459,

206133 (for Agents only), in place of 239368

Throat Plate Z39337 with 55326 and two 1208(809), in place of

239338

Throat Plate 239126 with 1198(803), 178Z5, 17828, 50018(806),

55459, 200138(805), 201711(803), 206133 and 239367, in place

of 239339

“I

6

6

M

9Z

9I-

I

1

NHDVW NOd SflIVd

EP

)j\

VOl KARkINC,

SAM I

lel.

I”To.

.

I ‘. r

No.

2.39415

239419

239411

23941 2

2392DB

124906

239414

8

2392.47

200064(803)

239413

239504

I( )R

t’v’l ALl uN I;

2.69 Wi I

SlWINC SIRAPS ON 1JNI)VRWE.AR,

AS MACI II NV 2.69w 8 Will I Ii IV 10

1

2

3

4

5

6

7

9

IS

i:TC.

I 0WiN0 EXCIJ-TIONS:

Description

A rch Clamp loot. Retajoing Plate

Feed Plate

Arch Clamp ‘oot (solid)

A rch Clamp Frame (offset universal) with two 2392.08

lranie Dowel Pin (2)

Arch Clamp Foot Lifter

Feed and Knife Driving Cam with 239247 and 2.00064(803),

of 239237

Tripping Point

Tripp:ing Point Screw

in place

Arch Clamp complete, Nos. 141575(805), 201526(805), 201711(803),

239206,

239209, 239248, 239411, 239412, 239415, 239419,

239473, 350602(819), 350605(869) and five 350132(819), in place

of 239210

Thread Wiper (quick acting) complete; Nos. 330(809), 39453, 124906,

141574(803), 200308(803), 239336, 239387 to 239389 (for Agents

‘)

only), in place of 239390

PARTS USED ON MACHINE 269W11 WHEN SPLIT FEET ARE NECESSARY

239418

239481

Arch Clamp Foot (left)

Arch Clamp Foot Shank (left) 239202 with 202(819) and 239418

239417

239482

Arch Clamp Foot (right)

Arch Clamp Foot Shank (right) 239204 with 202(8 19) and 239417

239483

Arch Clamp complete, Nos. 20152.6(805), 239201, 239207, 239209,

239248, •239249, 239419, 239473, 239481, 239482, 350602(819),

350605(869), two each 141575(805), Z01711(803), 239206, and

five 350 132(819), in place of 239413

o

))

M

I

&

9TflH

I

DVW iO1 S.UJVd

ij

1A k.’I’S

1()R

TvlAC1IIN I

Z(’) WI 2

VoI< LA kLIN(; .[()CKII’S ANI) (iLNI;RA L T3AJ{—TAC.K[Nc; Ol>VRATTON5

oliS VRS, S I_SACKS,

WORK i\ND SPOR’l’ c;LO’.FIIING,

UN1I’OR MS ANT) O’i’}iV R GARMIN’i’S.

SA ML AS MACI TINI

Ref.

No.

.1’; rI.

No.

1

239559

2

239471

3

239472

4

5

6

7

8

9

239247

200064(803)

200382(833)

201220(833)

200362(803)

200354(830)

Z69W8 Will! Ti-IF FOLLOWING LXCEPTIONS:

Dc sc r ipt:io

1 (cci and Knife Driving Cam with 239247 and 200064(803), in

iact of 239237

Vertical Drive Shaft Worm with 200382(833) and 201220(833), in

pLLCC of 239347

Vertical Drive Shaft Worm Gear with 200354(830) and 200362(803),

in place of 239348

T rippng Point

Tripping Point Screw

Worm Set Screw

Worm Position Screw

Worm Gear Set Screw

Worm Gear Position Screw

I

47

1’AkIS I’OI MACIflNI: Z()

WiZ

V() lAN(

( )N

i It )1j

ANI

R;, S I ,ACKS,

(;I;NI1Al JA1—rA(I1N(

; ()I’IiAIiONTS

W()RK A ND SPORT C LOTI

HNG,

Ii Ni I’()RfvlS A NI) O[11IR

CIA R1’.’l lN’IS.

2

A.kTV

F’Oi’

i’Ol

MACI I]NV

-I )V

26’)W ii

LACKING

A M V A MAC I IN V Z() WH W [‘I’ll

‘[1 I V FOLLOWING VXCVPT1ONS:

No.

No.

1

Z3)4bZ

2.

3

ZOOO64(U)3)

2.3)Z’17

Cal.. 3072.

I)escript;iori

V (‘(ci ;uid Kn ii’ J)jvjnr Cam with two

each Z39Z47 and OOO64($O3

in j)iaC(’ of Z3)Z37

‘iriJ)pil1g J?oint Scri’’v (Z)

‘i’rl)pifl;

1k)iiIt

(Z)

N’.L1 (16x100) Size 16

),

71

rn

--

r)

z

>

C

LI

H

-C

>

‘0

.1

1.5

iOi.

MACII[NE

lOP PAPP1NG .I>()(k11’S ON CI

VN IJA I

26) W26

TIlING ANI) OTI11R

IA1U I NC A N I) TACKING OPNRATION

S

SAM V AS MA( i1 IN V 2W) W8 WIt 1.1 ‘liii:

i’OLLO WING I;XCEPTIONS:

I i if.

No.

1

239130

2

2:39422

3

239423

4

5

6

7

8

9

10

206133

239485

140352(803)

200382(833)

201220(833)

200362(803)

200354(830)

Dc sc ription

iced and Knife Driving Cam with

239485 and three each 140352(803)

i.iid 2061 3 3, in place of 239237

Vertical Drive Shaft Worm with 200382(8

33) and 201220(833), in

place (ii 239347

Vertical Drive Shaft Worm Gear with 2003

54(830) and 200362(803),

in place of 239348

Tripping Point Screw Washer (3)

Tripping Point

TrippLng Point Screw (3)

Worm Set Screw

Worm Position Screw

W o r m Ge a r S e t S c r ew

Worm Gear Position Screw

r

/

‘C

c.

m

z

>

a

Lfl

>

F;

2

I. /\ 1<

.I( ).R iv! A C! 1TNJ 2.69 W .38

I()I l/\I8I[\k I[ JIl’ON!lI()!!;S I[\1 (1O11I1N(

siii AS NIA(:IIINI: /(9VV6 WI’[’ll !lJI .VQl1)VVTN

( lx(1;I’lIONS

:

LI

N.

I

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Z2

23

24

25

26

27

28

29

30

31

32

33

34

1);c ription

639%

A ruli ‘‘i’ l)Ot. 1’I!t 6.3984 ‘itJi 51041(80.3), 64954,

64955,

63986, two (aclI 1 90(809), 910(830) and I 601(809)

9 I I) ( 13. 0)

I.l. Aiju;tui’ ScJ(W (2.)

I 6(11 (110)) .A.I;LtiuI S(.J:(V/ NJi1. (Z)

6 -198 3

AdjLIstn Sc rew B ac1cI:

5

190(809) Adjusting Screw BricIcet Screw (2)

1611 (00i)

loot. Roller LLl( Screw Stud Nut: (2)

51854

loot: Rn lIe r and Screw Stud (eccentric) (2) with 1611(805)

V sit I iate with 1 7959

51 04[(803) loot. Sj) ri tig Screw

17959

loot Lifting Stud

63986

loot

ring

63955

Arch Clamp Foot (right) with 51854

63954

Arch Clamp Foot (left) with 51854

63949

Bell Crank Bracket

183(809) Bull Crank Bracket Screw (2)

239454

Bell Crank Connecting Rod Stop

201535(805) BcIl Crank Connecting Rod Stop Nut

239453

13el.l Crank Connecting Rod

28(803) Bell Crank 1-linge Screw

141(803) Pressure Spring Regulating Screw

63987

Clamp Pressure Spring

788(804) Pressure Spring Screw Stud

239455

Arch Clamp Frame (universal) with two 239208

167214

Starting Bell Crank, in place of 167143

167215

Crank 167214 with 51657(803), 53617(805), 167154 and

167155

239502

Arch Clamp Foot Lifter

239450

Feed and Knife Driving Cam with two each 239247 and 20006

4(803),

in place of 239237

405(803) Locating Finger Screw

35

200064(8 03) Tripping Point Screw

(

63947

Finger with +63969

36

239247

Tripping Point (2)

63965

Feed Plate

37

239208

Frame Dowel Pin (2)

63957

Foot Plate Cap (lower)

38

167155

Starting Rod Adjustor

63958

Foot Plate Cap (upper)

39

51657

Rod Lock Nut

63953

Clamp Closing Slide

40

167154

Starting Rod

239451

Bell Crank with +239452

41

53617

Swivel Stud Lock Nut

+63969

Arch Clamp Bar Locating Finger Pointer

+239452

Arch Clamp Closing Bell Crank Scud

239456