Download XBA Installation Guide & Service Manual(En) n

Transcript

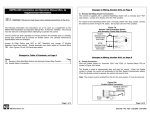

XBA Bill Acceptor Installation Guide & Service Manual XBA Use of Materials Limitations International Currency Technologies Corporation (ICT) all rights reserved. All materials contained are the copyrighted property of ICT. All trademarks, service marks, and trade names are proprietary to ICT. ICT reserves the right at all times to disclose or to modify any information as ICT deems necessary to satisfy any applicable law, regulation, legal process or governmental request, or to edit, refuse to post or to remove any information or materials, in whole or in part, in ICT's sole discretion. www.ictgroup.com.tw XBA Contents 1. General Information 1-1. Specifications..........................................................3 1-2. Dimensions............................................................. 4 1-3. Harness Application................................................ 5 1-4. Bezel Styles............................................................10 2. Software download and test 2-1. Download Firmware................................................11 2-2. Auto Testing Tool.................................................... 15 2-3. Component Names.................................................28 2-4. Assembling Procedure............................................29 3. Operation 3-1. Operation Flowchart...............................................36 3-2. I/O Circuit................................................................37 4. Maintenance..................................................................40 5. Troubleshooting 5-1. Introduction.............................................................41 5-2. Failed to Power Up.................................................42 5-3. Failed to Communicate...........................................43 5-4. Low Acceptance......................................................44 5-5. Wrong Credit Output...............................................45 5-6. Motor with Strange Sound......................................46 5-7. No Diagnostic LED Status......................................47 5-8. Bill Acceptor Error Code.........................................48 6. Parts and Assembly Views 6-1. Exploded Views......................................................58 6-2. Circuit Board Overviews.........................................64 7. Model Number Configuration.........................................65 www.ictgroup.com.tw XBA 1. General Information 1-1. Specifications General Acceptance Rate 98% or greater *Note: The acceptance rate excludes notes that are dirty, wet, broken or wrinkled. Bill Insertion Four way acceptable Transaction Speed Approx. 2.5 s to stack Interface Pulse, MDB, RS232 Installation Indoor & Outdoor Electrical Power Source 12V DC±10% 24V DC±10% 34V DC±10% Power Consumption Normal Mode- Standby : 0.15A, 1.8W Operation: 1.0A, 12W Maximum: 2A, 24W Power Saving Mode- Mode 1: 50µA Mode 2: 15µA Operation Environment Operation Temperature: -20°C~65°C Storage Temperature : -30°C~70°C Humidity: 30%~95%RH (no condensation) Mechanical Bill Box Capacity Approx. 200 bills 400 bills Weight Approx. 1.5kg Outline Dimension Refer to page 4 Bill Accepted Width 62~77mm -3- www.ictgroup.com.tw XBA 1-2. Dimensions t Two Sided Bezel 147[5.79]400bills 115[4.53]200bills 23.5[0.93] 83[3.27] 100.7[3.97] 400pcs. 200pcs. 107[4.21] 132[5.2] 116[4.57] 115[4.5] 238.5[9.39] ] 8[0.3] 22 0. 6[ 5. 83[3.27] 50.8[2.00] 48.6[1.91] 6- 104.2[4.10] (Figure.1) t TOB Bezel 104.2[4.10] 102[4.0] 117.5[4.63]200bills 300 pcs 100 pcs 106.3[4.18] 69.2[2.72] 25[0.98] 259.8[10.23] 153.3[6.04] 13.2[0.52] 20.2[0.79] 149.5[5.89]400bills 50.8[2.0] 117.5[4.63] 7.9[0.3] 81.2[3.20] (Figure.2) 101.2[4.0] Unit : m : m [inch] www.ictgroup.com.tw -4- XBA 1-3. Harness Application Interface Used Voltage 12VDC MDB Pulse ICT Protocol Usage Mode 6 WEL-RS7P02 6 WEL-RM006 7 Power & Data comm. WEL-RV701 7 Extension Wire CU-R961 8 Power & Data Comm. WEL-RV703 8 Extension Wire WEL-RV702 9 Power & Data Comm. WEL-RXBA18 9 Extension Wire CU-R961 Power & Data comm. 34VDC Normal 12VDC Sleep 24VAC Normal 12VDC Normal Page WEL-RV705 Sleep 12/24VDC Harness 8 (Table.1) *Data Comm. : Data Communication. -5- www.ictgroup.com.tw XBA Interface Used Voltage Mode Usage MDB 12V DC Sleep Power & *Data Comm. WEL-RV705 PIN 1- BLUE..........................+12VDC INPUT PIN 2- YELLOW..................................Ground PIN 3- PURPLE.............MDB_WAKE_UP_EN MOLEX 5559-06P PIN 4- ORANGE............MDB_MASTER_RXD PIN 5- RED....................MDB_MASTER_TXD BACK VIEW PIN 6- GREEN...........................MDB Ground 4 5 6 1 2 3 MOLEX 5559-06P 6 5 4 3 2 1 MOLEX 5557-6R BACK VIEW #WEL-RV705 MOLEX 5557-6R 1 2 3 4 5 6 DC 12V MDB 1 2 3 4 5 6 PIN 1- BLUE..................................+12VDC INPUT PIN 2- YELLOW..........................................Ground PIN 3- PURPLE.....................MDB_WAKE_UP_EN PIN 4- ORANGE....................MDB_MASTER_RXD PIN 5- RED............................MDB_MASTER_TXD PIN 6- GREEN...................................MDB Ground * * 2464 22AWG 6C CABLE 1 16 2 17 3 18 4 19 5 20 6 21 7 22 8 23 9 24 10 25 11 26 12 27 13 28 14 29 15 30 BLK-15*2 PIN 3- BLUE......................................+12V INPUT PIN 6- ORANGE..................MDB_MASTER_RXD PIN 14- RED..........................MDB_MASTER_TXD PIN 17- PURPLE...................MDB_WAKE_UP_EN PIN 20- YELLOW........................................Ground PIN 28- GREEN.................................MDB Ground (Figure.3) Interface Used Voltage Mode Usage MDB 12 / 24VDC Sleep Power & *Data Comm. WEL-RS7P02 4 5 6 1 2 3 MOLEX 5559-06P BACK VIEW PIN1 BLUE.......................DC+12/24V INPUT PIN2 YELLOW....................................Ground PIN3 PURPLE..............MDB_WAKE_UP_EN PIN4 ORANGE.............MDB_MASTER_RXD PIN5 RED......................MDB_MASTER_TXD PIN6 GREEN..............................MDB Ground 6 5 4 3 2 1 MOLEX 5559-6R BACK VIEW DC 12/24V MDB MOLEX 5559-06P #WEL-RS7P02 MOLEX 5557-6R 1 2 3 4 5 6 2464 22AWG 6C CABLE 1 2 3 4 5 6 PIN3 BLUE.....................................+12V INPUT PIN6 ORANGE.................MDB_MASTER_RXD PIN14 RED........................MDB_MASTER_TXD PIN17 PURPLE.................MDB_WAKE_UP_EN PIN20 YELLOW.......................................Ground PIN28 GREEN................................MDB Ground PIN1 BLUE............................+12VDC INPUT PIN2 YELLOW....................................Ground PIN3 PURPLE...............MDB_WAKE_UP_EN PIN4 ORANGE.............MDB_MASTER_RXD PIN5 RED.....................MDB_MASTER_TXD PIN6 GREEN.............................MDB Ground * * 1 16 2 17 3 18 4 19 5 20 6 21 7 22 8 23 9 24 10 25 11 26 12 27 13 28 14 29 15 30 BLK-15*2 (Figure.4) www.ictgroup.com.tw -6- XBA Interface Used Voltage Mode Usage MDB 34V DC Normal Power & *Data Comm. WEL-RM006 4 5 6 1 2 3 MOLEX 5559-06P BACK VIEW PIN 1- BLUE..............................................34VDC PIN 2- YELLOW.................34VDC Power Return PIN 3- .............................................................N/C PIN 4- ORANGE...................MDB_MASTER_RXD PIN 5- RED...........................MDB_MASTER_TXD PIN 6- GREEN.....................................MDB Groud #WEL-M006 MOLEX 5559-06P * * DC 34V MDB MOLEX 5557-6R 1 2 3 4 5 6 1 2 3 4 5 6 1 16 2 17 3 18 4 19 5 20 6 21 7 22 8 23 9 24 10 25 11 26 12 27 13 28 14 29 15 30 HORN-30 6 5 4 3 2 1 MOLEX 5557-6R BACK VIEW PIN 1- BLUE............................................34VDC PIN 2- YELLOW...............34VDC Power Return PIN 3- ...........................................................N/C PIN 4- ORANGE.................MDB_MASTER_RXD PIN 5- RED.........................MDB_MASTER_TXD PIN 6- GREEN...................................MDB Groud PIN 6- ORANGE...............MDB_MASTER_RXD PIN 14- RED.......................MDB_MASTER_TXD PIN 16- YELLOW............+34VDC Power Return PIN 23- BLUE...........................................34VDC PIN 28- GREEN.................................MDB Groud (Figure.5) Used Voltage Interface 12VDC Pulse Mode Usage Sleep Power & *Data Comm. WEL-RV701 2 1 6 5 4 8 7 9 +AMP AMP 172340-1 BACK VIEW DC 12V 3 * * #WEL-RV701 AMP 172340-1 1 2 3 4 5 6 7 8 9 PIN 1- YELLOW ........................................ INHIBIT+ PIN 2- GREEN ............................................ INHIBITPIN 5- RED ................................... +12V DC INPUT PIN 7- BLUE ....................... CREDIT_RELAY (N.O.) PIN 8- PURPLE ............... CREDIT_RELAY (C OM) PIN 9- ORANGE ............................................ GND PIN 1- PURPLE ............. CREDIT_RELAY ( COM) PIN 2- BLUE ................... CREDIT_RELAY ( N.O.) PIN 3- RED ................................ +12V DC INPUT PIN 4- YELLOW ..................................... INHIBIT+ PIN 18- GREEN ........................................ INHIBITPIN 20- ORANGE .......................................... GND 1 16 2 17 3 18 4 19 5 20 6 21 7 22 8 23 9 24 10 25 11 26 12 27 13 28 14 29 15 30 BLK-15*2 (Figure.6) -7- www.ictgroup.com.tw XBA Interface Used Voltage Mode Pulse 12V DC Sleep ICT Protocol 12V DC Normal Usage Extension Wire for WEL-RV701 Extension Wire for WEL-RXBA18 WEL-RU961 1 2 3 4 5 6 7 8 9 2 1 6 5 4 8 7 9 DC 12V 3 2464 22 AWG 6C CABLE #CU-R961-1 AMP 172332-1 202 202 202 202 202 202 PIN 1- YELLOW...............................INHIBIT+ PIN 2- GREEN.................................INHIBITPIN 5- RED......................... ..+12VDC INPUT PIN 7- BLUE...............CREOIT-RELAY(N.O.) PIN 8- PURPLE.........CREDIT-RELAY(COM) PIN 9- ORANGE....................................GND +AMP AMP 172340-1 BACK VIEW (Figure.7) Interface Used Voltage Mode Usage Pulse 24V AC Normal Power & *Data Comm. 3 2 1 6 5 4 8 7 9 +AMP AMP 172340-1 BACK VIEW AC 24V AMP 172340-1 1 2 3 4 5 6 7 8 9 #WEL-RV703 WEL-RV703 2464 22 AWG 6C CABLE PIN 1- PURPLE..............CREDIT_RELAY (COM) PIN 2- BLUE....................CREDIT_RELAY (N.O.) PIN 4- YELLOW.....................................INHIBITPIN 16- ORANGE..........................+24V AC (RET) PIN 18- GREEN........................................INHIBITPIN 23- RED.............................................+24V AC PIN 2- YELLOW............................................INHIBIT+ PIN 4- BLUE...........................CREDIT_RELAY (N.O.) PIN 5- PURPLE.....................CREDIT_RELAY (COM) PIN 5- GREEN...............................................INHIBITPIN 7- ORANGE.................................+24V AC (RET) PIN 8- RED....................................................+24V AC BLK-15*2 * * 1 16 2 17 3 18 4 19 5 20 6 21 7 22 8 23 9 24 10 25 11 26 12 27 13 28 14 29 15 30 (Figure.8) www.ictgroup.com.tw -8- XBA Interface Used Voltage Pulse 24V AC Usage Mode Normal Extension Wire WEL-RV702 3 2 1 6 5 4 8 7 9 +AMP AMP 172340-1 BACK VIEW AC 24V AMP 172332-1 202 202 202 #WEL-RV702 1 2 3 4 5 6 7 8 9 202 202 202 PIN 2- YELLOW................................................INHIBIT+ PIN 4- BLUE...............................CREDIT_RELAY (N.O.) PIN 5- PURPLE.........................CREDIT_RELAY (COM) PIN 5- GREEN...................................................INHIBITPIN 7- ORANGE.....................................+24V AC (RET) PIN 8- RED.......................................................+24V AC (Figure.9) Used Voltage Interface ICT Protocol Usage Mode Normal 12V DC Power & *Data Comm. WEL-RXBA18 4 8 7 9 +AMP AMP 172340-1 BACK VIEW PIN 1 PURPLE .....................CREDIT RELAY(COM) PIN 2 BLUE............................CREDIT RELAY(N.O.) PIN 3 RED........................................+12V DC INPUT PIN 4 YELLOW.............................................INHIBIT+ PIN 18 GREEN..............................................INHIBITPIN 20 ORANGE..................................................GND AMP 172340-1 1 2 3 4 5 6 7 8 9 DC 12/24V 1 5 D-SUB(F) 5 4 3 2 1 9 8 7 6 D-SUB 9F TOP VIEW PIN 2.......................RXD PIN 3.......................TXD PIN 5......................GND #WEL-RXBA18 2 6 ICT PROTOCOL #WEL-RXBA18 3 PIN1 YELLOW...............................INHIBIT+ PIN2 GREEN..................................INHIBITPIN5 RED............................+12V DC INPUT PIN7 BLUE.................CREDIT RELAY(N.O.) PIN8 PURPLE...........CREDIT RELAY(COM) PIN9 ORANGE......................................GND PIN 10- YELLOW........................GND PIN 25- RED................................VCC PIN 26- BLACK...........................TX11 PIN 27 -WHITE...........................RX11 1 16 2 17 3 18 4 19 5 20 6 21 7 22 8 23 9 24 10 25 11 26 12 27 13 28 14 29 15 30 BLK-15X2 (Figure.10) -9- www.ictgroup.com.tw XBA 1-4. Bezel Styles t Standard-Bezel Part Number: A421900-R 48.6[1.91] 2] 15[0.59] 33[1.30] 41.5[1.63] 12.4[0.49] 50.8[2.00] 78[3.07] 102[4.02] 2 [0. 9[0.35] 8[0.31] 5.5 24.5[1.0] 107[4.21] 116[4.57] 84.5[3.33] 83[3.27] (Figure.11) t T-Bezel Part Number: A422000-R 12.5[0.5] 106.3[4.18] 117.5[4.63] 153.3[6.04] 102[4.02] 81.2[3.20] 7.9[0.31] 5.2 [0.2 0] 30.5[1.20] 39[1.54] 50.8[2.0] 78[3.07] 84.8[3.34] (Figure.12) www.ictgroup.com.tw -10- XBA 2. Software download and test 2-1. Download Firmware 2-1-1. PC BA Step 1: Select Firmware File: File -> Open (Figure.13) Step 2: Select Firmware File & Press Open (Figure.14) Step 3: After opening , screen will display the file size and Checksum. (Figure.15) -11- www.ictgroup.com.tw XBA Step 4: Connection XBA & PC, turn on the XBA ,Press “Connect USB” (Figure.16) Step 5: Display Connect (Figure.17) www.ictgroup.com.tw -12- XBA Step 6: To set the DIP. Please select Set Dip Switch. And selecting DIP, Outside is a side DIP, Inside is an internal DIP. (Figure.18) Press Download. (Figure.19) -13- www.ictgroup.com.tw XBA Step 7: Download Success. (Figure.20) Step 8: After rebooting BA. Step 9: BA Version->Read Version. Check BA Version & Checksum. (Figure.21) www.ictgroup.com.tw -14- XBA 2-2. Auto Testing Tool 2-1-1. Connection Preparation before start A. XBA Auto test tool B. Connection cables(#WEL-RXBA06/#WEL-RHP57) C. Power source D. PC(OS Windows XP、Win7) E. XBA calibration card POWER WEL-RV701 WEL-RHP57 (Figure.22) XBA PC Step 1: Start the tool and make sure the version is the latest one. (Figure.23) -15- www.ictgroup.com.tw XBA Step 2: Enter the version and CheckSUM of this auto test tool. (Figure.24) www.ictgroup.com.tw -16- XBA Step 3: Press Connect USB. Message at upper left corner becomes “USB Connected”. It means the connection is successful. Turn off and turn on the BA and then the tool reads BA program version, shows the test items it will perform. (Figure.25) -17- www.ictgroup.com.tw XBA Step 4: Press the 【Start test】 button, the tool starts testing in order. (Figure.26) www.ictgroup.com.tw -18- XBA Step 5: 01 Fram Test 、02 I/O Sensor Test、03 Motor Test. It will appear “NG” if error happens. (Figure.27) -19- www.ictgroup.com.tw XBA Step 6: Calibration Test: Please insert XBA series calibration card. (Figure.28) www.ictgroup.com.tw -20- XBA Step 7: The message shows at the bottom left corner. (Figure.29) -21- www.ictgroup.com.tw XBA Step 8: Bill test. Please insert any Banknote for Accept Testing. (Figure.30) www.ictgroup.com.tw -22- XBA Step 9: Mask LED Test: Please check if the LED flashed the correct color and press OK or NG in the pop-up window. (Figure.31) Step 10: Stacker Test: Automatically perform stacking for one time, it will be listed as NG if error happens. -23- www.ictgroup.com.tw XBA Step 11: Pulse Test : Please check if the pulse the correct and press OK or NG in the pop-up window. (Figure.32) www.ictgroup.com.tw -24- XBA Step 12: Dip Switch Test: Please turn on/off the DIP switch according to the message at the bottom left corner. (Figure.33) -25- www.ictgroup.com.tw XBA Step 13: While testing “10 Cash box Test”, please remove and reinstall the cash box according to the message at the bottom left corner. (Figure.34) Step 14: Optical anti-stringing design Test, test Optical anti-stringing function. It will appear “NG” if error happens. www.ictgroup.com.tw -26- XBA Step 15: Flash Test There will be error message in the Test information if the read/write error happens. The “Issue” shows the result after the entire test: (Figure.35) -27- www.ictgroup.com.tw XBA 2-3. Component Names Stack Module CPU Door Bill Box Module M3x8 Screw with washer CPU Board ØM3*8 Self-tapping Screw Black Zinc Plated TP2 M4x12 Screw Upper Base Module Lower Base Module Standard Bezel Unit www.ictgroup.com.tw Main Module (Figure.36) -28- XBA 2-4. Assembling Procedure 2-4-1. Disassembly Procedure Step 1: Remove bill box. 3 1 2 (Figure.37) (Figure.38) Step 2: Loosen four screws to remove the bezel. Step 3: Remove the cover plate of main unit. (Figure.39) (Figure.40) -29- www.ictgroup.com.tw XBA Step 4: Loosen four screws to remove cpu board. Step 5: Press the snap on both left and right sides to remove the upper base. (Figure.41) Step 7: Loosen four screws to remove transmission module. Step 6: Loosen two screws to remove the Lower Base. (Figure.43) www.ictgroup.com.tw (Figure.42) -30- (Figure.44) XBA Step 8: 1. Remove the sensor unit top cover. 2. Remove Upper Base Waterproof Foam. Remove Upper Base Baffle Board. Waterproof Foam Baffle Board Waterproof long foam Sensor Board (Figure.45) 3. Disassembly IR LED/ Sensor mirror. (Figure.47) -31- (Figure.46) 4. Disassembly security hook. (Figure.48) www.ictgroup.com.tw XBA Step 9: 1. Loosen three screws to remove the Lower Base cover. 2. Remove Lower Base Water Proof Rubber. Loosen three screws to remove the LED board. Lower Base cover. Water Proof Rubber LED Board (Figure.49) (Figure.50) 3. Loosen four screws on the side to remove the Lower Base Gear Cover Plate. (Figure.51) www.ictgroup.com.tw -32- XBA 4. Loosen two screws to remove Lower Base Waterproof cover. 5. Remove two Plastic Axle Bush to take rubber wheels out. (Figure.52) (Figure.53) -33- www.ictgroup.com.tw XBA Step 10: 1. Disassembly transmission module. Loosen screw to remove Sensor board. 2. Loosen two screws to remove Block structure Rails. LED Board (Figure.54) 4. Remove E-ring. Pull the Belt Axle out. Remove Belt Roller. 3. Loosen four screws to remove Bill Sending Motor Set. (Figure.56) www.ictgroup.com.tw (Figure.55) -34- (Figure.57) XBA 5. Rise Stacker Board up. Remove E-ring. Remove Stacker Board. (Figure.58) 6. Loosen three screws to remove Stacker Motor. (Figure.59) 7. Remove E-ring. Pull the Belt Axle out. Remove Belt & Belt Roller. (Figure.60) -35- www.ictgroup.com.tw XBA 3. Operation Power On 3-1. Operation Flowchart No Check working voltage 10~15V? YES First time wake up? No YES Auto check All check ok NO YES No Exception Mode No YES Time Out Time Out NO Device ready YES NO Sleep Mode YES Time Out NO YES Sleep Mode Wait Bill insert YES Get pattern Bill Judge Sleep Mode NO Reject YES NO Laser detect Input Sensor Trigger? YES Is Fish? YES Power ON YES Reject NO Stack Stacking OK NO Exception Mode NO Time Out YES Sleep Mode (Figure.61) www.ictgroup.com.tw -36- XBA 3-2. I/O Circuit Pulse Interface. +5VDC~+12VDC +5VDC 4K7 Credit_Relay_NO Credit O/P Credit_Relay_COM Bill Acceptor Customer Side +5VDC~+12VDC +5VDC 1K Inhibit I/P Inhibit+ InhibitHi"TR ON Lo"TR OFF TR Bill Acceptor Customer Side Table.11 BA Status Inhibit Enable DIP SW Setting Inhibit Active Inhibit Active Control Signal Low Low High High Low High High Low (Figure.62) -37- www.ictgroup.com.tw XBA MDB Interface. +5VDC +5VDC~+12VDC TXD 1 8 2 7 3 6 4 5 MDB_MASTER_RXD Bill Acceptor Customer Side +5VDC RXD 1K +5VDC~+12VDC 8 1 7 2 6 3 5 4 MDB_MASTER_TXD 1K HiZTR ON LoZTR OFF Bill Acceptor Customer Side (Figure.63) www.ictgroup.com.tw -38- XBA ICT Interface. +5VDC +5VDC TXD TXD RXD Bill Acceptor 1K Customer Side +5VDC RXD TXD RXD Hi"TR ON Lo"TR OFF Bill Acceptor Customer Side (Figure.64) -39- www.ictgroup.com.tw XBA 4. Maintenance To make sure the bill acceptor always works smoothly, please clean the internal parts regularly. To clean the internal parts: 1. Press the buttons on the sides of bill path and pull the unit out. Buttons (Figure.65) (Figure.66) 2. Use a soft, dry cloth or towel to clean the bill path and sensors. Sensors Sensors (Figure.67) (Figure.68) (Figure.69) Maintenance Notice (Any improper maintenance will result invalid warranty.) Alcohol www.ictgroup.com.tw Recommended Mild, non-abrasive, soap water. DO NOT USE Organic solvent , Alcohol, Volatility liquid. -40- XBA 5. Trouble Shooting 5-1. Introduction INTRODUCTION Check if the unit is flashing in red error ? YES NO Refer to 5-8 Refer to 5-2 (Figure.70) -41- www.ictgroup.com.tw XBA 5-2. Failed to Power Up Failed to Power Up Make sure the input voltage is 12V DC. Make sure the harness connection is correct. Can power be applied to unit? NO Is there any pin or harnesses missing? YES Replace Power Line YES NO Replace CPU Board Test the unit by inserting notes. (Figure.71) www.ictgroup.com.tw -42- XBA 5-3. Failed to Communicate Failed to Communicate Is the connection to PC correct ? YES YES Can power be applied to unit? Is unit programmable? Reload the program NO NO Replace CPU Board Replace CPU Board NO Is the problem solved? YES Test the unit by inserting notes. (Figure.72) -43- www.ictgroup.com.tw XBA 5-4. Low Acceptance Low Acceptance Clean the bill path. Make sure the program is the latest version. Is the problem solved? NO YES Replace Sensor Board Is the problem solved? NO Replace LED Board Is the problem solved? YES Test the unit by inserting notes. NO Please contact ICT for technical support. (Figure.73) www.ictgroup.com.tw -44- XBA 5-5. Wrong Credit Output Wrong Credit Output Is credit multiplier used by the host? NO YES NO RS232 Pulse Check firmware for the denominations. Check DIP Switch for proper setting. Verify credit output independently. Is the problem solved? NO Replace Dip Switch YES Is the problem solved? Replace CPU Board Test the unit by inserting notes. (Figure.74) -45- www.ictgroup.com.tw XBA 5-6. Motor with Strange Sound Motor with Strange Sound Make sure belts, pulleys and wheels are in position. Is the problem solved? NO Replace Drive Motor Assembly YES Test the unit by inserting notes (Figure.75) www.ictgroup.com.tw -46- XBA 5-7. No Diagnostic LED Status No Diagnostic LED Status YES Can power be applied to the unit? Refer to 5-2 "Failed to Power Up" Replace CPU Board NO NO YES Is the problem solved? Replace LED or Sensor Board Test the unit by inserting notes. (Figure.76) -47- www.ictgroup.com.tw XBA 5-8. Bill Acceptor Error Code Flash of Diagnostic LED ONE Red Bill Jammed (See. 5-8-1) TWO Red Disabled From The System (See. 5-8-2) General Sensor Error (See. 5-8-3) THREE Red THREE+TWO Red Hook Sensor Error (See. 5-8-4) THREE+FOUR Red Fish Sensor Error (See. 5-8-5) A stringing attempt has been detected. (See. 5-8-6) FOUR Red FIVE Red Stacker Open (See. 5-8-7) SIX Red Stacker Error (See. 5-8-8) Motor Error (See. 5-8-9) SEVEN Red (Figure.77) www.ictgroup.com.tw -48- XBA 5-8-1. One Flash One Flash Bill Jammed Clean the bill path. Is the problem solved? YES NO Check hook sensor Is the problem solved? NO Replace Sensor or LED Board Test the unit by inserting notes. (Figure.78) -49- www.ictgroup.com.tw XBA 5-8-2. Two Flashes Two Flashes Disabled From The System Adjust Dip switch accordingly or Disable inhibit signal. Is the problem solved? NO Replace CPU Board YES Test the unit by inserting notes (Figure.79) www.ictgroup.com.tw -50- XBA 5-8-4. Three Flashes Three Flashes Sensor Error Clean the bill path. Is the problem solved? NO Replace LED Board Is the problem solved? NO YES Replace Sensor Board Is the problem solved? NO Replace CPU Board Test the unit by inserting notes. (Figure.80) -51- www.ictgroup.com.tw XBA 5-8-5. Three+Two Flashes Three + Two Flashes Hook Sensor Error Clean the bill path. Check hook sensor. Is the hook in position? NO YES Replace Hook Spring Is the problem solved? NO YES Replace Sensor Board Test the unit by inserting notes. (Figure.81) www.ictgroup.com.tw -52- XBA 5-8-6. Three+Four Flashes Three+Four Flashes Fish Sensor Error Clean the bill path. Is there anything blocking output sensor? YES Remove NO Replace output Sensor on Sensor board NO Is the problem solved? YES Test the unit by inserting notes. (Figure.82) -53- www.ictgroup.com.tw XBA 5-8-7. Four Flashes Four Blinks Flashes A stringing attempt has been detected. Clean the bill path. Power OFF Power ON Test the unit by inserting notes. (Figure.83) www.ictgroup.com.tw -54- XBA 5-8-8. Five Flashes Five Flashes Stacker Open Remove notes from the stacker. YES Is the problem solved? NO Check Stacker Open Sensor Unit YES Is the problem solved? NO Replace CPU Board Test unit by inserting notes. (Figure.84) -55- www.ictgroup.com.tw XBA 5-8-9. Six Flashes Six Flashes Stacker Error Remove bills and reset Unit. Is the problem solved? NO Make sure stacker cap is in position. NO Is stacker cap in position? YES Replace Stack Sensor Board Is the problem solved? YES YES NO Replace Stacker Motor Assembly Test unit by inserting notes. www.ictgroup.com.tw -56- (Figure.85) XBA 5-8-10. Seven Blinks Seven Flashes Motor Error Is there anything blocking the bill path? YES NO Replace Drive Motor Module Remove Is the problem solved? NO YES Replace CPU Board Test the unit by inserting notes. (Figure.86) -57- www.ictgroup.com.tw XBA 6. Parts and Assembly Views 6-1. Exploded Views XBA Main Module 11 5 10 9 3 8 7 1 4 7 6 5 4 3 2 1 SS399A S30660 A41990-R 3RMB-SBX85000 3RMB-FAC40000 3RMB-CAS17000 3RMB-DWN24001 3RMB-UPX18001 3RMB-CAS18000 CPU Board M3x8 Screw with washer XBA CPU Door 200P Bill Box Module Standard Bezel Unit Stack Module XBA Lower Base Module XBA Upper Base Module XBA Main Module 1 6 1 1 1 1 1 1 1 Quantity 8 4 Appellation 9 S30750 4 Part number 10 ØM3*8 Self-tapping Screw Black Zinc Plated TP2 (Table.2) M4x12 Screw 11 6 S40310 Order 2 (Figure.87) -58- www.ictgroup.com.tw XBA Upper Base Module 10 19 17 14 1 12 7 18 1 6 8 13 11 10 9 5 4 15 A4181000-R Spring Upper Base Unit 6 1 Quantity G11170 2 Appellation 1 Ldler Cover Part number 2 A21280-R Order 3 3 15 14 13 12 11 10 9 8 7 6 5 4 Z51370-R A42060-R G11290-R C23990-R Z51330-R Z51290-R S20060 D S30750 A41820-R A41860-R A41840-R A41830-R A33700-R A31460-R Upper Base Waterproof Foam Upper Base Baffle Board Mylar Leler Mount Burglarproof Hook Drawspring Upper Base Baffle Board Prism Dust Eraser Upper Base Dust Eraser Upper Base Waterproof cover LED light guide prism Upper Base Upper Cover Burglarproof Leler Mount Press Roller 1 1 1 2 1 1 2 1 1 2 1 1 4 6 (Table.3) 2 7 16 Z51380-R Sensor Board Ø3*8 Self-tapping Screw Black Zinc Plated TP2 2.3X6 Self-tapping Screw Black Zinc Plated TP2 17 SS399Hxx 2 18 19 16 (Figure.88) www.ictgroup.com.tw -59- XBA 8 13 3 4 16 14 9 15 21 6 7 1 5 11 10 19 18 2 17 (Figure.89) 9 8 7 6 5 4 3 2 1 S31240 A41940-R A41910-R A41960-R F10940-R F10880-R F11250-R Z51310-R A42070-R SS399Gxx A4189000-R Lower Base Gear Cover Plate (Left) M3x4 I Type Screw Black Zinc Plated Lower Base Gear Cover Plate (Right) Lower Base Waterproof cover Optical Shutter (30P) O Type Gear( M0.7x T15xW2) O Type Gear( M0.7x T25xW2) D Type Gear(M0.7xT10xW2) Lower Base Water Proof Rubber Roller D Type LED Board Lower base Module 1 4 1 1 2 2 2 2 2 2 1 1 Quantity 10 A41950-R 6 Appellation 11 Plastic Axle Bush Part number 12 A35390-R Order 13 2 4 Front Roller Axle 1 B15130-R 1 14 S30750 Ø3*8 Self-tapping Screw Black Zinc Plated TP2 Lower Base Water Proof Rubber 2 S10020 Z51300-R Lower Base Cover 15 16 A41900-R M3*8 Screw with washer 20 19 A41970-R Z51320-R Waterproof cover light guide O ring (P3) 2 2 8 17 S30660 E3-E Type Ring 18 21 (Table.4) -60- www.ictgroup.com.tw 20 12 Lower Base Module XBA 19 4 01 Stack Module 3 20 17 2 22 9 28 24 29 14 1 21 7 15 25 27 26 11 28 16 10 11 29 23 8 6 (Figure.90) 18 5 21 (Table.5) 4 4 4 E3-E Type Ring 2 Quantity S10020 Ø3*8 Self-tapping Screw Black Zinc Plated TP2 M3x8 Screw with washer 2 Appellation S30750 Belt Roller T30 Type D 2 M3x20 Round Head Screw with washer Part number 4 S30660 O Type Gear( M0.7x T25xW2) 4 S31430 5 A20740-R Belt Roller T20 Type O 1 1 Order 6 F10880-R Bearings-740ZZ(D7Xd4Xt2.5) 1 3 7 A29850-R Bill Stacking Structure Pedestal 1 M3x30 Round Head Screw with washer 8 J11140-R Right Scissors Unit 1 S31700 9 A4198000-R Left Scissors Unit 1 2 10 C2397000-R Stacker Motor 2 11 C2398000-R Bill Sending Motor Set (Right) Anti-skid Rubber 12 3RMB-MOT21000 Z50530-R 13 3RMB-MOT20000 3 14 28 27 26 25 24 23 22 21 20 19 18 17 16 A42250-R E50460-R G11170 A42040-R A42050-R B15150-R B15140-R B15160-R F12020-R A42010-R A42000-R SS399Fxx A42020-R 3RMB-MOT22000 Plastic E3-E Type Ring(3mm) Belt(140MXL-4.8W) Spring Press Roller Leler Mount Belt Axle (20T) Belt Axle Type D (25T) Belt Axle Type D (30) Spur Gears(M0.7X12T-D type) Block structure Rails L Block structure Rails R Cash Box Sensor Board Stacker Board Bill Sending Motor Set (Left) 6 2 2 2 2 2 2 2 2 1 1 1 1 1 1 15 29 www.ictgroup.com.tw -61- XBA Bill Box Module (200P) 12 11 3 13 2 10 16 9 1 5 4 14 15 8 7 6 (Figure.91) 9 8 7 6 5 4 3 2 1 B10860-R G1038A-R A2202A-R C20280-R J11160-R G11580-R A42170-R A42180-R A42120-R A42100-R A42110-R Door Link Spindle Tensional Spring of Door Link Door Link Spring Slider Pick Tensional Spring of Bill Pressed Board (0.3x3.0x10T) 1/4" Nylon Ball Bill Pressed Board Positioned lens Bill Box Door Plate Bill Box Top Cover Bottom Base Module of Bill Box 1 2 2 2 2 1 1 5 4 1 1 1 1 1 Quantity 10 G12040-R Vortex Spring Appellation 11 B13600-R Bills Supporting Board Part number 12 G11130-R Order 13 A42130-R 1 1 14 Bill Box Sticker 140 x 67 mm 15 16 (Table.6) -62- www.ictgroup.com.tw XBA Bill Box Module (400P) 13 10 9 17 11 16 18 8 4 19 12 2 14 7 15 6 1 5 3 (Figure.92) Order Part number Appellation Quantity A42170-R Tensional Spring of Bill Pressed Board (0.3x3.0x10T) 1/4" Nylon Ball Bill Pressed Board 1 4 4 1 1 G11580-R Pick 2 1 4 J11160-R Slider 2 Bottom Base Module of Bill Box 5 C20280-R Door Link 2 Bill Box Top Cover 6 A2202A-R Tensional Spring of Door Link 1 A42110-R 7 B10860-R Door Link Spindle 1 A42140-R 8 G12040-R Bills Supporting Board 2 1 9 B14500-R Bill Box Door Plate 1 2 10 A42160-R Scissors 1 11 A42150-R Vortex Spring Positioned lens 12 C23760-R A42180-R 13 G12710-R 3 14 S10010 B15060-R Spring E2-E Type Ring Scissors Spindle 1 4 2 1 15 16 G1038A-R 1 17 Bill Box Sticker 140 x 67 mm 18 19 (Table.7) www.ictgroup.com.tw -63- XBA 6-2. Circuit Board Overviews LED BOARD INPUT SENSOR 3BA-RSS399Gxx 3BA-RAA399Gxx 3BA-RSS399Fxx 3BA-RAA399Fxx SENSOR BOARD 3BA-RSS399Hxx 3BA-RAA399Hxx WEL-RQ705 WEL-RXBA07 FFC-RG12070 MOTOR DECODER CPU BOARD CPU BOARD 3BA-RSS399Exx 3BA-RAA399Exx 3BA-RSS399Axx 3BA-RAA399Axx 3BA-RSS399Axx 3BA-RAA399Axx WEL-RXBA02 (Figure.93) www.ictgroup.com.tw -64- XBA 7. Model Number Configuration XBA - X X X X X XX X X XX A B C D E F G H I J K A: Model E: Bezel I: Denominations B: Retention code F: Coating method J: Customer C: Voltage G: Interface K: Software Version D: Bill Box Capacity H: Currency (A): Mode Code Model XBA XBA Series (Table.8) (B): Retention code Code - Retention code (Table.9) (C): Voltage Code Voltage 1 DC 12V 2 DC 24V 3 DC 34V 4 AC 24V / DC 34V (Table.10) (D): Bill Box Capacity Code Bill Box Capacity 2 200 Bills 4 400 Bills (Table.11) -65- www.ictgroup.com.tw XBA (E): Bezel Code Bezel D Standard Bezel (Two-Sided) T T-Bezel (Table.12) (F): Coating method Code Coating method P PVD N Non-PVD (Table.13) (G): Interface Code Interface M MDB P Pulse R ICT002 (Table.14) (H): Currency : EU. Euro ( I ): Denominations Code Denominations 1 1 Denomination 2 2 Denominations 3 3 Denominations 4 4 Denominations 5 5 Denominations 6 6 Denominations 7 4 Denominations (Table.15) (J): Customer Customer Code (Table.16) (K): Software Version : 00~99 www.ictgroup.com.tw -66- Taiwan International Currency Technologies Corporation Ji-Hong Building, No 24, Alley 38, Lane 91, Nei-hu Rd., Sec. 1, Taipei, Taiwan, R.O.C. Tel: 886-2-2797-1238 ‧ Fax: 886-2-2797-1634 [email protected] (For Sales) ‧ [email protected] (For Customer Service) Website: www.ictgroup.com.tw www.ictgroup.com.tw 2013 International Currency Technologies Corporation V. 1.0 Part Number: H