Download MOD-IO development board user`s manual

Transcript

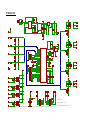

MOD-IO development board user's manual All boards produced by Olimex are ROHS compliant Rev. C, March 2013 Copyright(c) 2011, OLIMEX Ltd, All rights reserved Page 1 INTRODUCTION MOD-IO is a small but powerful development board who let you control 4 optoisolated input and 4 relay outputs - with this features is possible to turn on and off almost any electronic device at home. The board has UEXT_FEMALE connector which allows you to communicate with a PC and UEXT_MALE connector where you can connect other Olimex board with UEXT. The MOD-IO project is fully open software and open hardware. The customer has full access to the documentation of the board including schematics and board design. The main idea of MOD-IO chain connection is to extend: - isolated relay outputs - isolated digit inputs - non isolated analog inputs - non isolated digit inputs/outputs using UEXT male/female connector. So the MCU interfaces (I2C, SPI, UART) from all chain boards are connected in parallel. Note that if you want to connect more than 1 MOD-IO board then on the interface bus (I2C or UART or SPI) has to have only one Master device. The other devices have to be Slaves. For example: if UART interface is used - the master will send a string with Slave address and command. All Slaves will listen UART bus through RXD line while all Slave TXD lines are inputs. So when the address is recognized from the Slave device, the one will answer as it will force TXD pin like output but immediately after command answer is finished the Slave TXD pin must be initialized like input. The same principle can be used for other interfaces (SPI or I2C). BOARD FEATURES – Microcontroller: Atmega16L – AVRISP connector – JTAG connector – EXT connector – UEXT_MALE – UEXT_FEMALE – Clock circuit – User button – Reset circuit and button – Power Jack – Power-on led – Nine status leds – Four optocoupler isolated inputs Page 2 – Four Relays – PCB: FR-4, 1.5 mm (0,062"), solder mask, silkscreen component print – Dimensions: 100x80 mm (3.94x3.15") Page 3 ELECTROSTATIC WARNING The MOD-IO board is shipped in protective anti-static packaging. The board must not be subject to high electrostatic potentials. General practice for working with static sensitive devices should be applied when working with this board. BOARD USE REQUIREMENTS Cables: Hardware: Software: The cable you will need depends on the programmer/debugger you use. If you use AVR-PG1, or AVR-JTAG, you will need RS232 cable, if you use AVR-PG2, you will need LPT cable, if you use AVR-USBJTAG, AVR-ISP500, AVR-ISP500-TINY, AVR-ISP500-ISO, AVR-ISPMK2 you will need 1.8 meter A-B USB cable. One of Olimex programmers/debuggers – AVR-PG1, AVR-PG2, AVR-ISP500, AVR-ISP500-TINY, AVR-ISP500-ISO, AVR-JTAG, AVRUSB-JTAG, AVR-ISP-MK2 or other compatible programming/debugging tool. Make sure to check if the above programmer/debugger is supported by the IDE you are going to use. AVR C Compiler PROCESSOR FEATURES MOD-IO use 8-bit AVR Microcontroller with 16K Bytes In-System Programmable Flash, with these features: – High-performance, Low-power AVR® 8-bit Microcontroller – Advanced RISC Architecture – – 131 Powerful Instructions – Most Single-clock Cycle Execution – 32 x 8 General Purpose Working Registers – Fully Static Operation – Up to 16 MIPS Throughput at 16 MHz – On-chip 2-cycle Multiplier High Endurance Non-volatile Memory segments – 16K Bytes of In-System Self-programmable Flash program memory – 512 Bytes EEPROM – 1K Byte Internal SRAM – Write/Erase Cycles: 10,000 Flash/100,000 EEPROM – Data retention: 20 years at 85°C/100 years at 25°C – Optional Boot Code Section with Independent Lock Bits In-System Programming by On-chip Boot Program True Read-While-Write Operation Page 4 – – – Programming Lock for Software Security JTAG (IEEE std. 1149.1 Compliant) Interface – Boundary-scan Capabilities According to the JTAG Standard – Extensive On-chip Debug Support – Programming of Flash, EEPROM, Fuses, and Lock Bits through the JTAG Interface Peripheral Features – Two 8-bit Timer/Counters with Separate Prescalers and Compare Modes – One 16-bit Timer/Counter with Separate Prescaler, Compare Mode, and Capture Mode – Real Time Counter with Separate Oscillator – Four PWM Channels – 8-channel, 10-bit ADC 8 Single-ended Channels 7 Differential Channels in TQFP Package Only 2 Differential Channels with Programmable Gain at 1x, 10x, or 200x – – – Byte-oriented Two-wire Serial Interface – Programmable Serial USART – Master/Slave SPI Serial Interface – Programmable Watchdog Timer with Separate On-chip Oscillator – On-chip Analog Comparator Special Microcontroller Features – Power-on Reset and Programmable Brown-out Detection – Internal Calibrated RC Oscillator – External and Internal Interrupt Sources – Six Sleep Modes: Idle, ADC Noise Reduction, Power-save, Power-down, Standby and Extended Standby I/O and Packages – – Operating Voltages – – 2.7 - 5.5V Speed Grades – – 32 Programmable I/O Lines 0 - 8 MHz Power Consumption @ 1 MHz, 3V, and 25⋅C – Active: 1.1 mA Page 5 – Idle Mode: 0.35 mA – Power-down Mode: < 1 µA Page 6 BLOCK DIAGRAM Page 7 MEMORY MAP Page 8 Page 9 SCHEMATIC G1 DB104(SMD) PWR_J VR1(5V) 8 4 YDJ-1134 8-30 VDC 2 R1 3.3V 3 150k C4 1uF/50v 220uF/35V +5V EN 5 VIN LM1117IMPX-ADJ SW 1 INV N.C. GND 7 FB IN 100uH/SW68 RT 6 100n 110k REL4 D9 RAS-05-15 1N4148/SMD OUT ADJ/GND C5 R2 C3 green O4 3.3V VR2(3.3V) L1 BD9001FSO-8 C1 4n7 C2 PWR_LED red R7 R4 D1 1N5819(smd) R3 8.2K REL4 R37 OUT4-3 OUT4-2 1K C6 240R/1% C7 R6 100n 390R/1% 10n C9 C8 OUT4-1 R8 0R AIN-1-1 100n O1 1K R35 T4 BC817 1K GND R36 R5 AIN-1-2 Fmax=50kHz R19 AN1 100R R20 C20 NA 33nF 10K 2K green O3 R9 100R RST AIN-1-3 TB2/3.5mm R21 AN2 100R R22 C21 NA 33nF 10K O[1..4] R23 AVRISP AN3 100R C22 R24 33nF NA 2 1 4 3 6 5 8 7 10 9 RST R11 AN4 100R STAT yellow C23 R26 3.3V 330R 3.3V TB2/3.5mm RST 3.3V 1 4 3 6 5 8 7 10 (ADC7)PA7 31 (ADC6)PA6 AN3 32 (ADC5)PA5 AN4 O4 O3 O2 O1 33 (ADC4)PA4 34 (ADC3)PA3 35 (ADC2)PA2 36 (ADC1)PA1 37 (ADC0)PA0 Q2 REL3 RST 4 RESET 7 XTAL2 1 C12 33p C13 Q1 8MHz/20pF 8 XTAL1 33p (SCK)PB7 2 (MISO)PB6 1 (MOSI)PB5 44 (SS)PB4 43 (AIN1)PB3 42 (AIN0/INT2)PB2 41 (T1)PB1 40 (T0)PB0 26 (TOSC2)PC7 25 (TOSC1)PC6 24 PC5(TDI) 23 PC4(TDO) 22 PC3(TMS) 21 PC2(TCK) 20 PC1(SDA) AREF AVCC AGND TCK TDO TMS TDI 9 O2 GND R38 TDI TDO TMS TCK 1K R39 NA 10K 3.3V 29 100n green O2 27 C15 28 REL2 RAS-05-15 1N4148/SMD 100n SDA SCL VCC2 19 PC0(SCL) 16 (OC2)PD7 2 15 (ICP)PD6 3 14 (OC1A)PD5 13 (OC1B)PD4 12 (INT1)PD3 11 (INT0)PD2 10 (TXD)PD1 9 (RXD)PD0 REL2 D7 R43 OUT2-3 OUT2-2 1K VCC VCC1 1 T3 BC817 3.3V C14 3 OUT3-1 2 VCC MCP130T C11 OUT3-2 1K RESET OUT3-3 R40 U2 3.3V 32768Hz/6pF JTAG 2 30 GND 33nF NA AIN-2-3 AN1 AN2 SCK MISO MOSI #SS LED I2 I3 I4 BH10S AIN-2-2 D8 REL3 1N4148/SMD RAS-05-15 3.3V T1107A(6x3.8x2.5mm) R10 100n AN[1..4] 3.3V AIN-2-1 C10 5 OUT2-1 17 O3 38 R41 T2 BC817 1K R42 10K IN4-2 + red LED4 U6 R27 3.9k I1 1 D5 1N4148/SMD IN4-1 2 4 I1 3 + H11A817SMD 3.9k D4 1N4148/SMD IN3-1 + 3.9k D3 1N4148/SMD 4 2 3 I2 + IN1-1 - 3.9k 100n 100n 100n green O1 39 REL1 D6 RAS-05-15 1N4148/SMD 1 2 H11A817SMD OUT1-3 OUT1-2 OUT1-1 O4 2 REL1 R46 47K I3 3.3V 3.3V 3.3V 3.3V 3.3V R44 1K 3.3V T1 BC817 R45 10K 4 I3 R32 R12 47K 3 4.7K R13 I4 red LED1 U3 D2 1N4148/SMD 18 ATMEGA16L H11A817SMD R33 C18 R30 - IN1-2 C17 O[1..4] 1 1 IN2-1 GND2 C16 1K red LED2 U4 R31 GND1 I2 H11A817SMD - IN2-2 6 EXT WF6S red LED3 U5 R29 I1 BUT TXD RXD 5 47K - IN3-2 4 R28 GND 6 4 3 I4 R34 47K 100n NA R15 R16 R17 R18 4.7K NA 4.7K 4.7K BUT 100R C19 R14 BUT T1107A(6x3.8x2.5mm) UEXT_MALE RXD1 SCL3 5 MISO SCK7 9 BH10S UEXT_FEMALE 2 TXD SDA MOSI 10 #SS 4 6 8 1 RXD SCL3 5 MISO SCK7 9 2 TXD SDA MOSI 10 #SS 4 6 8 IDC10S/PCB This schematic is released under the Creative Commons Attribution-Share Alike 3.0 United States License. MOD-IO_rev_A1 https://www.olimex.com OLIMEX LTD, Plovdiv, Bulgaria, 2013 BOARD LAYOUT POWER SUPPLY CIRCUIT MOD-IO is typically power supplied with 8-30V DC. Power consumption when all relays are working is about 310 mA. CLOCK CIRCUIT Crystal Quartz 8 MHz connected to Atmega16l pin 7 (XTAL2) and pin 8 (XTAL1). Crystal Quartz 32.768kHz connected to Atmega16L pin 25 ((TOSC1)PC6) and pin 26 ((TOSC2)PC7). RESET CIRCUIT MOD-IO reset circuit includes Reset scheme MCP130T (U2), AVRISP connector pin 5, JTAG connector pin 6, Atmega16L pin 4 (RESET), R9 (100Ohm), R10 (10k), C10 (100nF) and RST button. Page 11 CONNECTOR DESCRIPTIONS AVRISP Pin # Signal Name 1 MOSI 2 3.3V 3 NC 4 GND 5 RST 6 GND 7 SCK 8 GND 9 MISO 10 GND Pin # Signal Name 1 TCK 2 GND 3 TDO 4 3.3V 5 TMS 6 RST 7 3.3V 8 NC 9 TDI 10 GND Pin # Signal Name 1 PD7 2 PD6 3 PD5 4 PD4 5 3.3V 6 GND JTAG EXT Page 12 UEXT_MALE More info available here: https://www.olimex.com/Products/Modules/UEXT/ Pin # Signal Name 1 NC 2 GND 3 RXD 4 TXD 5 SCL 6 SDA 7 MISO 8 MOSI 9 SCK 10 #SS Pin # Signal Name 1 NC 2 GND 3 RXD 4 TXD 5 SCL 6 SDA 7 MISO 8 MOSI 9 SCK 10 #SS UEXT_FEMALE Page 13 IN1, IN2 IN3, IN4 Please note that the opto-isolated inputs IN1, IN2, IN3, IN4 in earlier revisions were able to receive signals in the 3V to 6V range. R27, R29, R31, R33 were 330R and R28, R30, R32, R34 were R4.7k. We have now adjusted the values of the resistors in that part of the schematic in latest revisions to allow higher voltage input in the 3.3V-24.0V range. R27, R29, R31, R33 are now R3.9k and R28, R30, R32, R34 are now R47k Pin # Signal 1 - 2 + IN1 connected to (T0)PB0 – signal I4 IN2 connected to (T1)PB1 – signal I3 IN2 connected to (AIN0/INT2)PB2 – signal I2 IN4 connected to (INT1)PD3 – signal I1 OUT1, OUT2, OUT3, OUT4 OUT1 connected to (ADC3)PA3 – signal name O4 OUT2 connected to (ADC2)PA2 – signal name O3 OUT3 connected to (ADC1)PA1 – signal name O2 OUT4 connected to (ADC0)PA0 – signal name O1 AIN-1 Please note that the analog inputs by default are as big as the input levels but you might change this. Just calculate the needed resistors R19/R20 and R21/R22. Pin # Signal Name Connected to 1 3.3V VCC 2 AN1 (ADC7)PA7 3 AN2 (ADC6)PA6 Page 14 AIN-2 Please note that the analog inputs by default are as big as the input levels but you might change this. Just calculate (and mount/replace) the needed resistors R23/R24 and R25/R26. Pin # Signal Name Connected to 1 AN3 (ADC5)PA5 2 AN4 (ADC4)PA4 3 AGND Analog GND PWR_J Pin # Signal Name 1 Power Input 2 GND Page 15 JUMPER DESCRIPTION There are no jumpers on this board. INPUT/OUTPUT User button with name BUT – connected to Atmega16L pin 11 ((INT0)PD2). Reset button with name RST – connected to Atmega16L pin 4 (RESET). Status LED (yellow) with name STAT – connected via R11 (330 Ohm) to Atmega16l pin 43 ((AIN1)PB3). Status LED (red) with name LED1 – visualize input (IN1) state. Status LED (red) with name LED2 – visualize input (IN2) state. Status LED (red) with name LED3 – visualize input (IN3) state. Status LED (red) with name LED4 – visualize input (IN4) state. Status LED (green) with name O1 – visualize relay (REL1) state. Status LED (green) with name O2 – visualize relay (REL2) state. Status LED (green) with name O3 – visualize relay (REL3) state. Status LED (green) with name O4 – visualize relay (REL4) state. Power-on LED (red) with name PWR_LED – shows that +3.3V voltage is applied to the board. Page 16 MECHANICAL DIMENSIONS Page 17 AVAILABLE DEMO SOFTWARE There are two firmware available for MOD-IO: one is for RS232 control and the other is for I2C control. They might be found at the web page of MOD-IO. Direct download links: – – MOD-IO I2C (newer) firmware C source and hex MOD-IO RS232 (older) firmware C source and hex Page 18 ORDER CODE MOD-IO assembled and tested. How to order? You can order directly from our web shop or from any of our distributors. The list of distributors might be found here: https://www.olimex.com/Distributors. Check our web https://www.olimex.com for more info. Revision history: Board's revision: Manual's revision: Rev. A - create November 2009 Rev. B – edited September 2011 added more detailed INTRODUCTION and MECHANICAL DIMENSIONS Rev. C – edited March 2013 added new schematic, more information about AIN and IN inputs; IN input voltage adjusted; updated disclaimer and product support Page 19 Disclaimer © 2013 Olimex Ltd. Olimex®, logo and combinations thereof, are registered trademarks of Olimex Ltd. Other product names may be trademarks of others and the rights belong to their respective owners. The information in this document is provided in connection with Olimex products. No license, express or implied or otherwise, to any intellectual property right is granted by this document or in connection with the sale of Olimex products. The Hardware project is released under the Creative Commons Attribution-Share Alike 3.0 United States License. You may reproduce it for both your own personal use, and for commercial use. You will have to provide a link to the original creator of the project https://www.olimex.com on any documentation or website. You may also modify the files, but you must then release them as well under the same terms. Credit can be attributed through a link to the creator website: https://www.olimex.com The software is released under GPL. It is possible that the pictures in this manual differ from the latest revision of the board. The product described in this document is subject to continuous development and improvements. All particulars of the product and its use contained in this document are given by OLIMEX in good faith. However all warranties implied or expressed including but not limited to implied warranties of merchantability or fitness for purpose are excluded. This document is intended only to assist the reader in the use of the product. OLIMEX Ltd. shall not be liable for any loss or damage arising from the use of any information in this document or any error or omission in such information or any incorrect use of the product. This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation purposes only and is not considered by OLIMEX to be a finished end-product fit for general consumer use. Persons handling the product must have electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental measures typically found in end products that incorporate such semiconductor components or circuit boards. Olimex currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive. Olimex assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or services described herein. THERE IS NO WARRANTY FOR THE DESIGN MATERIALS AND THE COMPONENTS USED TO CREATE MOD-IO. THEY ARE CONSIDERED SUITABLE ONLY FOR MOD-IO. Page 20 For product support, hardware information and error reports mail to: [email protected]. Note that we are primarily a hardware company and our software support is limited. Please consider reading the paragraph below about the warranty of Olimex products. Warranty and returns: Our boards have lifetime warranty against manufacturing defects and components. During development work it is not unlikely that you can burn your programmer or development board. This is normal, we also do development work and we have damaged A LOT of programmers and boards during our daily job so we know how it works. If our board/programmer has worked fine then stopped, please check if you didn't apply over voltage by mistake, or shorted something in your target board where the programmer was connected etc. Sometimes boards might get damaged by ESD shock voltage or if you spill coffee on them during your work when they are powered. Please note that warranty do not cover problems caused by unproper use, shorts, over-voltages, ESD shock etc. If the board has warranty label it should be not broken. Broken labels void the warranty, same applies for boards modified by the customer, for instance soldering additional components or removing components - such boards will be not be a subject of our warranty. If you are positive that the problem is due to manufacturing defect or component you can return the board back to us for inspection. When we receive the board we will check and if the problem is caused due to our fault and we will repair/replace the faulty hardware free of charge, otherwise we can quote price of the repair. Note that all shippings back and forth have to be covered by the customer. Before you ship anything back you need to ask for RMA. When you ship back please attach to it your shipping address, phone, e-mail, RMA# and brief description of the problem. All boards should be sent back in antistatic package and well packed to prevent damages during the transport. Page 21