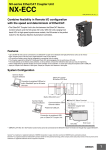

Download NX7 Machine Automation Controller CPU Unit Hardware

Transcript