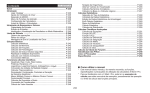

Download Elta® R 45, Elta® R 55, Elta® R 50 Routine Total

Transcript