Download USER`S MANUAL

Transcript

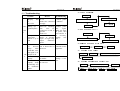

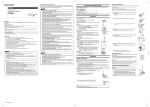

R R XH-KG55B XH-KG55B XH-KG55B Temperature Controller USER’S MANUAL 一 OVERVIEW XH-KG55B is a in telligen t te mpe ra tu re con tro lle r, design ed by object’s charac teristics, con tro lling progra mmed te mpera tu re according to proc ess cu rse . It simplifie s syste m op era tion of KG66 and d ecrea ses outpu t in te rfac e, to going to sma ller an d mo re intelligen t d irection. A nd it is strong versatile , fit for controlled te mpe ra ture wh ich is less than 15 0 ℃ , i.e. wash ing mechan ism an d ele ctric hea te r. 二 MAIN SPECIFICTIONS 2.1 I/O interfaces 1 inpu t ch anne l fo r te mpera ture mea sure men t 3 outpu t ch anne ls with switch ing variab le o f which : 2 he ating c ontro ls 1 ca ll con tro l rela y ou tput: AC 240V/3A 2.2 Temp erature con trol specifications te mp era ture me asu re me nt co mponen t P t100 pla tin u m the rmo -resistor : 1 R R XH-KG55B :000.0℃~153.0℃ te mp era ture con tro l ran ge :030.0℃~150.0℃ te mp era ture con tro l a cc urac y : sta ble error ≤± 1.2 ℃ te mp era ture me asu re me nt range 2.3 Programmable Functions prog ra mmab le p rocess No .: (0 ~ 9 ) , to ta l 10 P rogra mma ble p rocess step s of each p rocess is ten. Each step is b e set ob jec t te mp era tu re, gradient and iso the rm time. 2.4 Temperature Control Method: optimize self-adaptive method 2.5 Temperature p arameters setting range :( 030.0 ~ 150.0 )℃ g rad ien t :( 0.2 ~ 9.9 )℃ /min time o f iso the rmic phase :( 00 ~ 9 9 ) min ob jec t te mperatu re 2.6 Programming Checkout Functions P ress “△” ke y to check wheth er se tting para mete rs correspon d with pa ra meters in the process flo wcha rt or no t. 2.7 Safekeeping ( 1) Suddenly powe r cu t o ff, a run ning con tro ller can con tin ually run in retrie ving the old proc e ss step data after powe r is on a gain. 2 XH-KG55B R R XH-KG55B XH-KG55B Reader’s Card (2) During run ning p robe is Dear Sir, broken, the con troller calls 18 times, then it stops. (3) When te mpe ra ture is hig her than 150 Thank you for accepting our product. Ple ase fill in Re ade r’s Card and se nd to us. We ’d like to give you e xce lle nt se rvice . ℃, the controlle r ca lls and au to matica lly stop s. 2.8 Power Range AC ✄ (180~250)V、50/60HZ ≤3W Power consumption 2.9 Dimension o f Apparatus Type of Controller W(96)×H(96)×L(100)mm Qty. 3 2.10 Dimension o f I nstallatio n W(92)×H(92)mm Date 2 2.11 Work Environment Company Temp era ture Contac t Pe rson ≤ 50 ℃ re la tive hu mid ity ≤ 90 % 三 OPERATING GUIDE Te l. 3.1 Add ( 1) RST Functional Keys When press it,”P” will flash on pan el. In runnin g sta te pu sh STOP at first, then p ush RS T. P.C. ( 2) PRG Advice : —— : Add:Building1NanhaiTiananCyberPark,FoshanGuangdong Tel 0757-81230666 Fax 0757-81230666 —— P r e s s i t t o g o t o p r o g r a m m i n g s t a t e . —— In re se t sta te press it to displa y F*L* , it ( 3) RUN means process No. & step No. After en te r F*L* it sta rt to run . During running press it to d ispla y process No. & step No for 3 sec s. 3 14 R R XH-KG55B (4)STOP — — In op era ting sta te pre ss it to XH-KG55B pause Problem controlle r. —— (P age up ) P ress it to page u p da ta o f each step (5) in sequence and me mo rize p ara meters. And ch eck Can’t program. operation progra m step b y step. (6) ——( ——( P age down )P ress it to page do wn data o f ea ch error step in sequen ce. And c heck prog ra m in nega tive step. “ 0 ~ 9 ” ——( —— (number)Enter decimal number 0~9. (8) —— ( shift righ t ) Dig ital displa ying p lace sh ifts (7) towa rds righ t. When controller is on, it’s in isothermic phase. STOP and RST key can’t be operated. 3.2 Operating Flowchar t F — pro cess No . L — step No . i.e . pro cess No .: F2, step No .: L1 Can’t run to next step. (1)program: p r e s s 【 R S T 】 to display P press 【 P R G 】 to display F0L0 enter【F2】,press【►】to input【L1】 press【 ▲ 】 memorize and page up 4 enter data & next step press【 ▲ 】 memorize Don’t display. Abnormal enter end code 00000000 press 【 R S T 】 Reason Don’t push RST or PRG key. Don’t enter finish code 00000000 in programming mode. Troubleshooting Program again. Or turn on controller to program again. Up-gradient rate and down-gradient rate is set 00 in programming mode. Quickly push STOP and RST key, it can return to normal state. Check error parameter and program again. Set data is unsuitable, i.e., set temp is 30 Readjust set time is 10 parameters. min. But actual temp is higher than 30 in summer. ℃, ℃ Press STAET key of sampling dyeing machine, but keys can’t run rightly. It results in wrong initial state. Cut off power for 8-10 seconds, then power on again. 八 Service A wa rran ty of time fo r ou r produc t is o ne yea r. We pro vid e ou r custo me rs with consisten t b est a fter-sale s support. If you h a ve an y p roble m, p lea se don ’t hesitate to contac t with u s. 13 R R XH-KG55B ( 2) Check Progra m: 8.0 Troubleshooting Problem ℃ Display Probe 000 ℃ or 153 Instable temp during upgradient phase Circu it Temp inaccurate which is up to 95 ℃ Val ve Can’t increase or decrease temp when controller runs, but lights is on. Output is ok. Increase temp slowly Increase temp rapidly. Temp continually rise in isothermic phase XH-KG55B Reason P robe circuit is short or cut. Probe flex connected wrongly. Joins in probe line or three-core insulating line can’t be connected or bad to ground. Probe wet. Water come into probe. It become vapor at high temp. Vapor influences probe. AC contactor can’t run or heated flex is burnt out.. display P Troubleshooting Check probe and lines. Check and connect probe line again. Blow out water in probe, then seal and fix it. If necessary, change new one. Maintain external electric apparatus. press 【 0~9】 to display F0L0 press press enter F*L* ( 3) Run process( F2 L1) display P enter F 2 L1 press 【 RUN】 to display F0L0 press 【 RUN】 to start ( 4) Re-run proce ss after halt running state running state change a new one 【RST】 : p r e s s S TO P ( 5) Process Step Jump: Power of heated flex is smaller. AC contactor is bad or can’t run. 【 ▲】 to check press STOP press press RUN △ towards object process push RUN twice ( 6) Process Param eters Correction : display P press △ p r e s s P R G t o d i s p l a y F 0L0 modify data press △ enter F*L* press 【 R S T 】 12 5 R R XH-KG55B 3.3 Subroutine Fu n ction (1) Running pau se sub.161 00000 & e nd sub .00000 000 , XH-KG55B ℃) Temperature ( Ω) PT100 resistor( 24 109.352 26 110.230 28 110.904 30 111.670 40 115.540 50 119.400 60 123.240 70 127.070 80 130.890 90 134.700 d ispla y - 5. 100 138.540 B If chan ge ne w IC, re -se t te mp correc tion p rogra m. If ne edn ’t correc t te mp , ple ase se t 16200000 . 110 142.290 120 146.060 C 130 149.820 And temperature correction subroutine is 16200000. Only there 140 153.580 is old apparatus and bad probe, we have to correct temperature. 148 156.570 150 157.310 the co ntrolle r stops and calls. (2)Te mp era ture co rrec tio n : i.e. enter F9 L9, se e corre ction func tion as belo w, 162 000 0 9 0 subroutine No. Note A △ press to memorize ~9: max corrected temp is 9℃ 0—positive correction 1—negative correction : 、 During runn ing pu sh ( 0 ~ 9 ) ke y to disp la y corre cte d te mp, i. e. +5 、 ℃ ,℃ displa y 5 -5 、 Temperature deflection of KG55B is less than ±0.6℃. ℃ The corrected temp value is used under 99 after the controller is in isotherm time 20mins. It is right correction method that 6 Start contro ller to pre -he at for 3 min s. bits standard resistor corresponds with standard temperature. Moreover, three-core insulating line can’t effect measured Then calib rate low p oint 50 temperature within 50 meters. 130 6 ℃ and h igh poin t ℃ . P rimarily ca lib rate th is two po ints and then o the rs. Te mpe ra ture deflec tion of each poin t is less than 0.6 ℃。 11 R R XH-KG55B 1 XH-KG55B 4.0 Operation Attention 17 (1 )The last bit flashes in isotherm phase, not flashing in up- 2 CALL 3 18 gradient temperature phase. It is to identify if setting temperature is equal with real temperature or not. PT100 19 (2 ) It is ea sy to start at an y proc ess No .(F) & step No.(L). 4 20 0 5 HEAT 1 COM21 (3) Handle abno rma l situ ation : If abn ormal situa tion happens in ope ra tion , cut o ff powe r for 5secs before th e con tro ller ru ns aga in o r press RST. 22 HEAT 2 23 6 24 (4) Opera tion of ke ys should be on for one se cond to a void error. 7 25 (5) When programming, set temperature had better to be integer(set zeroes after decimal point). KG55B Back Panel d iagram 2 7.0 Method of Temperature Calibration (6 ) In ru nning sta te push STOP to o nly displa y te mpra ture of d ye ing ta nk. (7 ) If c orrecting pro cess p ara me ters, nee dn ’t sh ift last p lace to pre ss △ to pag e up “ ” Replace P T100 with 6 b its sta ndard re sistor. ℃) Temperature ( 10 Ω) PT100 resistor( (8) We pro vide . custo me rs with gene ra l softwa re withou t te mpe ra ture c orrec tion. If cu sto mers ha ve 10 103.900 special 20 107.790 corre ction software. 22 108.576 o rde r, we can give you te mpe ratu re 7 R R XH-KG55B 5.0 Explanation of Programming , i.e. proce ss No. F2 ste p No . XH-KG55B 6.0 Diagram of KG55B Output Connection L0 . hold ing te mperatu re 8 0℃ fo r 30 END up -g rad ient XH-KG55B DYEING CONTROLLER 1.5℃ / min a mbie nt te mperatu re TEMP (℃) *GRAD (℃ /min) *TIME (min) * Diagram of Programming No action setting gr a d isotherm t e mp (℃ /min ) time (℃ ) 8 Process HOLD CALL RUN No.F * (min ) Step No L * 1 press RST P 2 press PRG F0L0 enter F*L* 3 press 0~ 0~9 F2L0 enter F2 4 press 000.0 0.0 0 0 enter data 5 set parameters 1 .5 3 0 F2L1 6 press △ 0 8 0. 0.0 000.0 0.0 0 0 enter data 7 set end program 000.0 0.0 0 0 F2L2,set 0 8 press RST P △ HEAT end 0~9 RUN STOP PRG RST R FOSHAN HANSUNG AUTOMATION Co., Ltd. KG55B Front Panel Diagram 1 9