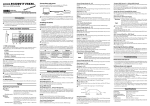

Download MSS Controller/Microstepping Motor Drive User Manual

Transcript