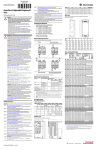

Download 520-QS001 - Rockwell Automation

Transcript