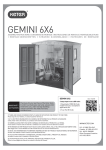

Download to - Automatic Doors

Transcript