Download Tecumseh AWA9490ZXTHN Performance Data Sheet

Transcript

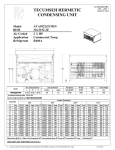

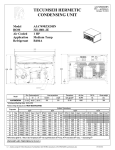

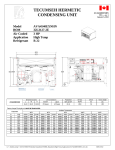

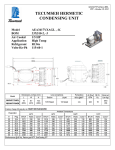

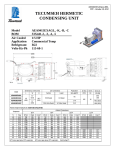

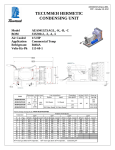

AWA9490ZXTHN TPC___REV 1 March 21, 2012 TECUMSEH HERMETIC CONDENSING UNIT Model BOM Air Cooled Application Refrigerant AWA9490ZXTHN 32L1902-2E 1 HP Commercial Temp R404A 36.25 35.38 25.50 23.50 26.08 4.24 SUCTION 5/8" SWEAT LIQUID 3/8" SWEAT Dim. Enclosure(inch)* L W H Model AWA9490ZXTHN 31.50 40.50 Line connections Suction Liquid 5/8 26.75 Pumpdown o 90% @ 90 F 20.16 3/8 Air flow SCFM Oil Ch. Oz. Gross weight Lbs. 1800 38.6 320 *) Enclosure Mounting Holes, 38.5 x 25.5 Factory charge 20 psig dry air, MUST BE EVACUATED Evaporator o F -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 Psig 23.2 27.5 32.1 37.0 42.4 48.2 54.5 61.2 68.4 76.1 84.4 93.2 103.0 113.0 o BTUH 4800 5900 7300 8800 10500 12300 14100 16000 17900 19700 21500 23100 24600 25800 80 F Watts Head Cond T 1300 206 91 1350 208 91 1410 211 92 1480 214 93 1560 217 94 1650 221 96 1730 226 97 1810 231 99 1890 238 101 1960 245 103 2010 253 105 2050 262 107 2070 272 110 2080 283 113 o BTUH 3700 4600 5700 7000 8400 9900 11500 13100 14800 16300 17800 19100 20300 21200 Ambient Temeratures o o 95 F 100 F Watts Head Cond T BTUH Watts Head Cond T 1230 251 105 3300 1200 268 109 1280 255 105 4100 1260 272 110 1350 258 106 5200 1330 276 111 1440 262 107 6400 1420 280 112 1530 267 109 7700 1520 284 113 1630 271 110 9200 1620 289 115 1730 277 111 10700 1730 295 116 1840 283 113 12200 1840 301 117 1940 290 115 13800 1950 308 119 2030 297 117 15200 2050 315 121 2110 306 119 16600 2150 323 123 2180 315 121 17900 2230 333 125 2240 325 124 18900 2290 343 128 2270 337 126 19800 2340 354 130 o o o o BTUH 2500 3200 4100 5200 6400 7700 9100 10500 11900 13200 14400 15500 16400 17000 110 F Watts Head Cond T 1150 306 119 1210 310 120 1290 314 121 1380 318 122 1490 322 123 1610 327 124 1730 333 125 1850 339 126 1980 345 128 2100 353 130 2210 361 131 2310 370 133 2390 380 135 2460 391 138 o Performance @ 60 Hz ; Return Gas Temperature 20 F max superheat above 20 F evap, 40 F max below 20 F evap ; --- SubCooling 5 F PRELIMINARY PERFORMANCE DATA L:\~ Andreea temp\ZZ Follett Datasheets\TecDataSheet Info\WORD_datasheets\AWA9490ZXTHN_REV1.doc 21/03/2012 AWA9490ZXTHN TPC___REV 1 March 21, 2012 Parts/Specifications STANDARD Unit BOM Unit MODEL 32L1902-2E AWA9490ZXTHN Refrigeration RANGE Design Pressure Low Design Pressure High Volts - HZ - Ph Voltage Range Min. Circuit Ampacity Max. Fuse Size -10°F to 45°F 181 450 200-230V 3~ 60HZ 180 - 254 9.94 15 Compressor MODEL Compressor BOM Compressor LRA Compressor RLA AW616RT-121-A2 AWA9490ZXT 51 4.70 OverLoad Relay Run Capacitor Run Capacitor Rating Start Capacitor Start Capacitor Rating Contactor 91014B Unit Drawing Wiring Diagram DGU1918-L305 WD23-2FM OPTIONAL Fan Motor Fan Motor Qty Fan Motor RLA Fan Blade Fan Guard Shroud 810F050C20 2 0.7 51568 70831 70648-2 High Pressure switch Low Pressure Control Dual Pressure Conrol 84095-2L 84026-2 Condenser Head Master Valve Check Valve Process Valve Liquid Valve Suction Valve 50855-1 70083-1 56626 Receiver Receiver Qty Accumulator Liquid Filter Sight Glass Suction Filter 51099-2L 1 CrankCase Heater 91022-1 Fix.Fan Switch #1 (F opt.) Fix.Fan Switch #2 (F opt.) Adjus. Fan Ctrl. (A opt.) Defrost Clock (Tn option) Defrost Heaters Contactor Rec. Heater (R option) Solenoid Valve (loose) Disconnect (D option) 84132-01 Wiring with F option Wiring with A option WD23-2AT2 Phase Monitor, ICM402 900-10026 BOM INDEX DESCRIPTION 56500-K06 56500-10K 32xYYYY- 2ERA(F)TnDS E Enclosure R Receiver Heater A Adjustable fan control F Fixed fan Control T1 Defrost timer option T2 Defrost timer & Defrost Heaters Contactor D Disconnect S Solenoid liquid Valve (supplied loose) 70081-3 70084 70822-6S NOTES IMPORTANT: COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD PROTECTOR. ALLOW TIME FOR RESET. USE COPPER CONDUCTORS ONLY. (EMPLOYER DES CONDUCTEUERS DE CUIVER SEULEMENT.) FIELD WIRING NOTES 1. ALL FIELD WIRING MUST BE DONE IN COMPLIANCE WITH ALL APPLICABLE LOCAL AND NATIONAL CODES. 2. CONNECT INCOMING POWER LEADS FROM POWER SUPPLY TO L1, L2, AND L3 IN COMPRESSOR CONTACTOR OR TO L1, L2 AND L3 IN DISCONNECT SWITCH (IF PROVIDED). USE COOPER CONDUCTORS ONLY. (EMPLOYER DES CONDUCTEURS DE CUIVER SEULEMENT.) PROVIDE EQUIPMENT GROUNDING CONDUCTOR. USE 75°C (MIN.) WIRING FAN 1 FAN 2 GENERAL NOTES: A. CONTACTOR COIL CIRCUIT IS FACTORY CONNECTED TO 230 V SOURCE IN TO "Y-OUT" AT PHASE MONITOR COMPRESSOR CONTACTOR COIL see note A HP LP A B D.T. C TERMINAL BOARD P1 PANEL AS SHOWN B. COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD PROTECTOR. ALLOW TIME FOR RESET. TO "230 VAC" AT PHASE MONITOR L1 FFC TO "C" AT PHASE MONITOR L2 AFC L3 T1 T3 F1 F2 LP POWER SUPPLY 230-60-3 LOW PRESSURE CONTROL HP L3 T3 L2 T2 L1 T1 TO "P1" AT TERMINAL BOARD ADJUSTABLE FAN CONTROL HIGH PRESSURE SWITCH TO "L2" AT TERMINAL C BOARD A D.T. B TO "L1" AT TERMINAL BOARD DISCHARGE THERMOSTAT GRD FACTORY COMPONENTS CRANK CASE HEATER L1 L2 L3 T1 T2 T3 Y C 115 230 VAC VAC OPTIONAL FACTORY COMPONENTS ICM402 3 PHASE MONITOR COMPRESSOR TERMINAL L1 L2 L3 BLACK R CONDENSING UNIT WIRING, 230V 60Hz 3 Ph, fixed fan control, PHASE MONITOR OPTION RED YELLOW REVISION L:\~ Andreea temp\ZZ Follett Datasheets\TecDataSheet Info\WORD_datasheets\AWA9490ZXTHN_REV1.doc AUG. 18, 2009 C S YOUT WD23-2FM 21/03/2012