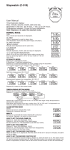

Download Tiger Series User Manual

Transcript