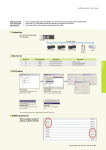

Download "user manual"

Transcript