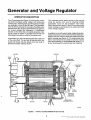

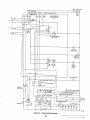

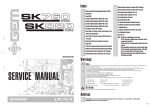

Download Generator and Controls

Transcript