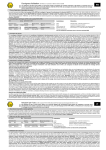

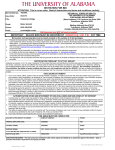

Download Quality Control - Density User Manual

Transcript